News / Events

Stay up to date with us

Meet the Glatt team at Vitafoods Europe 2024 in Geneva at stand L 173

From the idea to market with functional granules. With a short time-to-market from product and process development directly to contract manufacturing or your own production plant Benefit from bundled expertise in particle design - from the first feasibility test to scale-up, masterbatch and validation of the production process. Glatt offers suitable solutions for almost every requirement. With Glatt process technologies, you can optimize and functionalize your products of tomorrow today! Visit us at stand L173.

Particle design + Plant engineering. Glatt at ChemProTech India 2024

Discover the perfect symbiosis to produce bulk material with maximum functionality for their intended use. At Glatt, we go beyond the ordinary. Discover the future potential for YOUR production. Immerse yourself in a world where your visions of tomorrow are already taking shape today. ChemProTech India in Mumbai – April 24 - 25. Save the date and meet us in Hall 1 at Booth J07

Novel Foods Group and Glatt for new biotech cluster in the UAE

We are very happy to be part of this project! Novel Foods Group, the Abu Dhabi based global pioneer in the alternative proteins sector, together with several esteemed global engineering companies have announced a landmark agreement to commence the planning phase of a USD500mn biotech production site located in the UAE. The agreement was signed during the inaugural Healthy Innovation Conference (HiConf) held recently in Dubai.

Particle design + Plant engineering. Glatt at Anuga FoodTec

Februrary 2024: Discover with Glatt the future potential for your production when drying liquids into powders and granulates with defined properties. Benefit from the unique combination of technological expertise in bulk solids particle design and plant engineering from a single source. Visit us at Anuga FoodTec - Stand 10.1 G 060.

Upscaling of fluidized bed Wurster processes

March 5, 2024 | 9:45 a.m. Hotel Leonardo Weimar. Save the date! The lecture presents an upscaling concept for fluidized bed processes with Wurster configuration developed and established by Glatt. It is suitable for coating and agglomeration processes alike. The concept is based on basic thermodynamical and fluid mechanical principles, resulting in reliable scaleup factors. Speakers are Dr. Sören E. Lehmann and Dr. Norbert Pöllinger, Glatt Pharmaceutical Services

Copyright: Glatt

Copyright: GlattCoating of cohesive powders using chemical vapor deposition in a fluidized bed reactor

March 5, 2024 | 11:10 a.m. Hotel Leonardo Weimar. Save the date! The lecture presents a novel coating process based on chemical vapor deposition (CVD). In this process, fine, cohesive pigment powders are coated with thin carbon layers. These materials are used in the cosmetics industry and are characterized by exceptional visual properties. The speaker is Dr. Christian Rieck, Glatt Ingenieurtechnik

BioCampus MultiPilot plant as a catalyst for industrial biotechnology

13.12.2023 - Industrial biotechnology is one of the key technologies for the transformation of the economy towards greater sustainability. In recent years, there have been increasing calls from research and industry for more capacity to scale up new processes. Thomas Luck, Director Business Development, MultiPilot Plant, BioCampus Straubing (German Article)

Copyright: Glatt

Copyright: GlattPhosphorus recovery by Glatt PHOS4green at CRU Phosphates 2024 at stand 36

With PHOS4green, we have developed an innovative patent-protected technology to recover the essential nutrient phosphorus from sewage sludge ashes and use it for new phosphate or compound fertilizers. Recovery of phosphorus from ashes. Direct conversion into fertiliser granules. Heavy metal depletion. Meet us at the CRU Phoaphates 26-28 February 2024 in Warsaw, Poland at stand 36 and learn more about our proven technology.

Copyright: ZVH Straubing

Copyright: ZVH StraubingGlatt wins follow-up order for BioCampus MultiPilot in the port of Straubing-Sand

Straubing/Germany, December 2023 – Weimar based Glatt Ingenieurtechnik GmbH will be responsible for the Detail engineering and delivery of integrated process technology for the multipurpose BioCampus MultiPilot (BMP) demonstration facility in the port of Straubing-Sand. The flexible platform, to be used to scale-up and commercialise innovative biotech processes and sustainable products, will enable start-ups, research groups and industrial companies to further develop, test scale up and optimise their biotechnological processes to pre-industrial scale, validate their economic viability and produce material samples.

Copyright: ISTMAG – ISTANBUL MAGAZINE GROUP

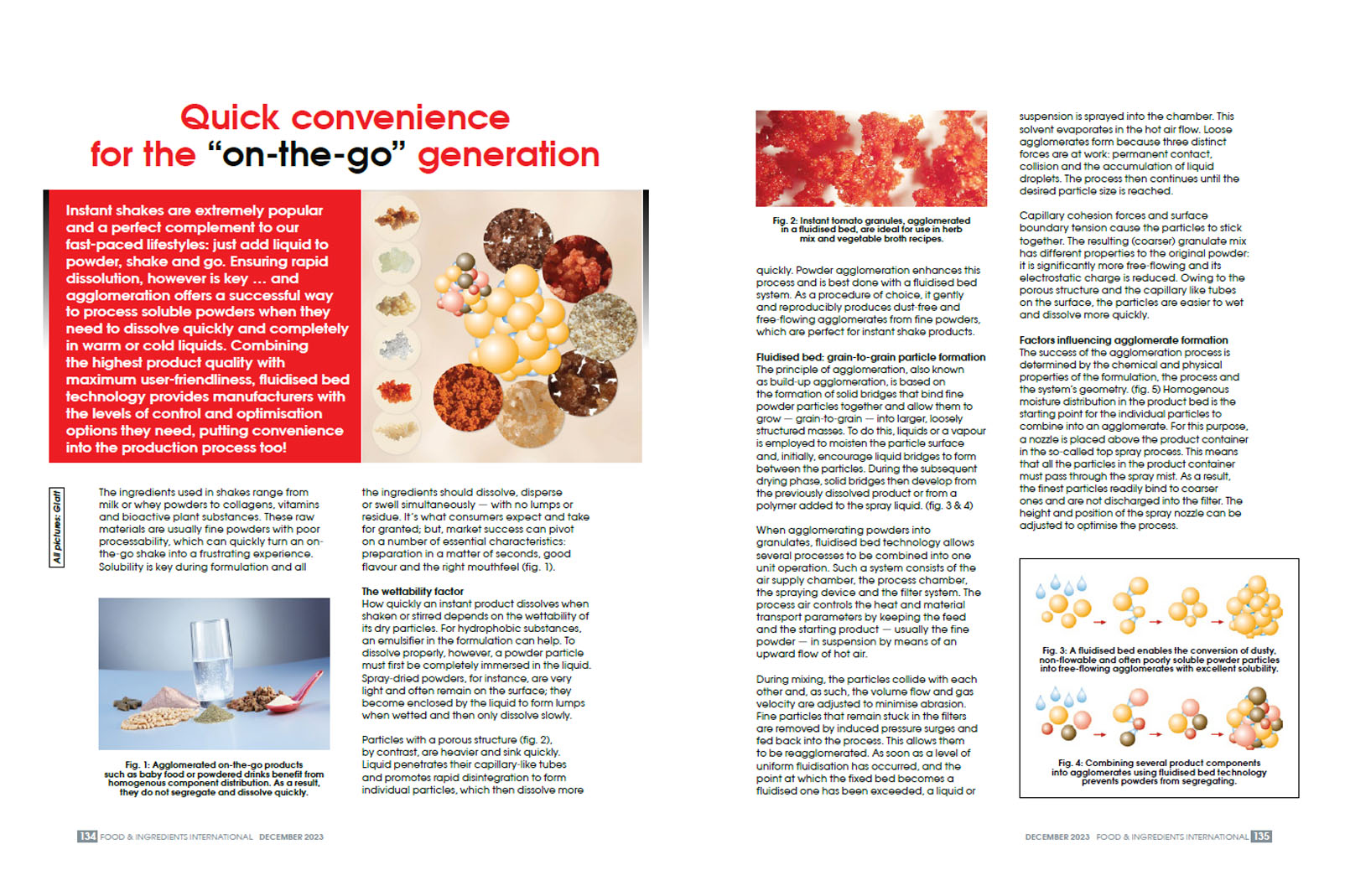

Copyright: ISTMAG – ISTANBUL MAGAZINE GROUPQuick convenience for the “on-the-go” generation by powder agglomeration

Instant shakes are extremely popular and a perfect complement to our fast-paced lifestyles: just add liquid to powder, shake and go. Ensuring rapid dissolution, however is key … and agglomeration offers a successful way to process soluble powders when they need to dissolve quickly and completely in warm or cold liquids. Combining the highest product quality with maximum user-friendliness, fluidised bed technology provides manufacturers with the levels of control and optimisation options they need, putting convenience into the production process too!

Copyright: Glatt

Copyright: GlattGlatt Particle Design for Food Ingredients at the FI Europe 28.-30.11.2023 in Frankfurt

We explain how flexible fluidized bed processes can realize your product ideas. Particle size and particle structure can be specifically adjusted. This gives you a direct influence on characteristics such as bulk density, solubility, dispersibility, release behavior and flowability. Improved dosing and storage stability extend the range of applications for the subsequent processing of your optimized ingredients. Fluid bed spray granulation for highly soluble protein granules with improved sinking behavior. Fluidized bed coating enables tailor-made encapsulation of spherical and irregular particles.

Copyright: Glatt

Copyright: GlattGlatt Webinar on ‘Aerosol-based processes for the production of battery materials’ 15. November 2023. Virtual Battery Day

The increasing demand for applications within electromobility or stationary energy storage requires the implementation of novel, sustainable and continuous manufacturing processes as well as processes for coating active materials. Aerosol-based methods based on spray drying / spray calcination and spray granulation by powder synthesis and fluid bed technology are presented using selected examples. First results on electrochemical characterisation are shown.

Copyright: Inter-Euro Medien

Copyright: Inter-Euro MedienExploring new ways to produce cosmetic pigments – Interview with Merck and Glatt about the cooperation and the project

Using completely new technology, pigment specialists at Merck and Glatt Ingenieurtechnik’s technology and production experts have worked closely together to produce an innovative range of cosmetic pigments. The Darmstadt-based Merck Group placed an order for the development and construction of a plant based on chemical vapour deposition (CVD) after successful joint trials at Glatt’s location in Weimar. We interview the partner companies about the cooperation and the project.

Copyright: Glatt

Copyright: GlattMeet the Glatt experts at 15th University Course Fluidization Technology

Dr. Michael Jacob, Head of the Process Engineering Department at Glatt Ingenieurtechnik GmbH, will give a lecture on "Vacuum drying in fluidized beds". This will be part of the 4-day program around fundamentals and applications in drying, granulation and agglomeration.

Copyright: Glatt

Copyright: GlattMeet the Glatt Experts @ SEPAWA Congress ● Stand E723 ● October 25-27, 2023 ● Berlin ● Germany

Learn more about the the interrelationships of influencing factors in the formulation of sustainable homecare products. Meet the Glatt experts and figure out the potential of different technologies in terms of product structures and application properties. Check out the process options of fluid bed and spouted bed technology for value-adding product forms at the annual SEPAWA Congress round about the detergents/cleansers, cosmetics and fragrance industry in Europe.

Copyright: Glatt

Copyright: GlattSafety concepts. Heat recovery. Environmental compatibility. Meet the Glatt experts at Powtech 2023. Booth 2-216

Glatt will be presenting cutting-edge safety concepts that go far beyond current legal requirements. As a plant manufacturer and operator, Glatt combines professional engineering with extensive technological know-how from its own practical experience. Visitors to the stand can discover which comprehensive concepts and innovations Glatt has developed and how they pay off in terms of product quality, fire/explosion protection, operational safety, heat recovery and environmental compatibility.

Copyright: Glatt

Copyright: GlattMeet the Glatt Experts at Alimentaria Foodtech from 26-29 September 2023 – Barcelona at booth E563

Transform poorly free-flowing powders into dust-free, easy-flowing granules! Adjust the solubility of your instant products! Increase the bioavailability of active ingredients. Stabilize oxidation-sensitive and volatile substances. Encapsulate your additives for better transportability and storability with clever particle coatings! Discover fluid bed or spouted bed processes!

Jens Lehnert, Funkemedien

Jens Lehnert, FunkemedienManaging Director Reinhard Böber leaves Glatt Ingenieurtechnik GmbH to retire

Dr Reinhard Böber is leaving the management of Glatt Ingenieurtechnik GmbH on 1 September to begin his well-earned retirement. He co-founded the company 32 years ago with the "Continuous Fluidised Bed" research group of the Magdeburg Heavy Engineering Combine (SKET) in Weimar and was largely responsible for the company's development. Dr Böber's farewell ceremony was attended by shareholders, executives and partners of the Glatt Group, as well as numerous representatives from Thuringia's business community, society and politics.

Copyright: Glatt

Copyright: GlattMeet the Glatt Experts at Food Ingredients India from 17-19 August 2023 – Bombay Exhibition Centre in Mumbai in hall 1 at booth S10

Transform poorly free-flowing powders into dust-free, easy-flowing granules! Adjust the solubility of your instant products! Increase the bioavailability of active ingredients. Stabilize oxidation-sensitive and volatile substances. Encapsulate your additives for better transportability and storability with clever particle coatings! Discover fluid bed or spouted bed processes!

Copyright: Jens Lehnert

Copyright: Jens LehnertGlatt joins forces with Merck for cosmetic pigment production – Festive inauguration of the Dryflux facility

On 30 June 2023, a completely new type of production plant for special effect pigments was officially commissioned at the Glatt Technology Centre. The Darmstadt-based Merck Group placed the order for the development and construction of a plant based on chemical vapour deposition (CVD). The Dryflux technology is suitable for numerous powder applications.

Talk about Your Particle Design Ideas with the Glatt Powder Processing Experts at IFT 2023, booth 4230

IFT first. July 16 -19, 2023 / Chicago, IL. Visit the Glatt particle customization specialists at booth 4230. Our team will be happy to discuss a wide range of topics — from product ideas to contract manufacturing as well as to full production machines with production ranges from tens of kilograms to multiple tons per hour. Feasibility Trials. Equipment Design & Build. Site Services. Plant Layout & Design.

Copyright: Glatt

Copyright: GlattGlatt lecture on Spray Granulation vs. Spray Drying of Hydrolyzed Proteins – Istanbul, May 31, 2023

'Spray Granulation vs. Spray Drying – Fluid Bed Technology as an Innovative Drying Process for Hydrolyzed Proteins?' Lecture by Dr. Jens Bergman, Glatt Ingenieurtechnik / Food & Nutritional Ingredients 2023 in Istanbul - May 31, 16:45 - 17:15. Save the date or meet us in Hall 10 at Booth D201. Together with our Turkish partner Pulse Group, we answer your questions about particle design of bulk solids from liquids and powders.

Copyright: Glatt

Copyright: GlattGlatt experts for particle design and plant engineering at EXPOQUIMIA from 30.05. – 02.06.2023 in Barcelona

Particle design + plant engineering. A perfect symbiosis for the production of bulk materials with optimal properties and functionality. With Glatt technologies such as fluid bed or spouted bed as well as with powder synthesis in pulsating gas flow, you can influence parameters such as particle strength, particle size, bulk density, solubility and many more. Visit us in Hall 3 at Booth 152. Our team will be happy to answer your questions.

Meet the Glatt Experts at CHEMUK from 10-11 May 2023 – in Birmingham, UK at stand D30

Glatt will be exhibiting at CHEMUK2023, Britain’s leading trade fair for bulk, fine and specialty chemicals, which will be held at the National Exhibition Center in Birmingham on 10th and 11th of May 2023. Visit us at booth D30 and exchange ideas with our experts. Please approach our specialists with questions that cover the entire bandwidth from feasibility trials, product development, conceptual studies up to the engineering of tailor-made production plants.

Copyright: LEG Thüringen

Copyright: LEG ThüringenGlatt Ingenieurtechnik honored as a “Hidden Champion” made in Thuringia

The State Development Corporation of Thuringia (LEG) launched its new marketing campaign “Hidden Champions – Thuringia’s world market and technology leaders” with a kick-off event on 3 March 2023. They didn’t have to look far to identify 89 companies that are at the forefront of the market in their industry. Among them is Glatt in its capacity as a leading specialist for plant engineering and processes in fluid bed and spouted bed technology as well as the patented powder synthesis.

Glatt Particle Design for Additives and Fillers at ECS 2023 – Booth 3-732

The product requirements of paints and coatings are versatile, but the properties of commercially available fillers or additives are often not. Glatt experts will explain how this gap can be closed with optimised powders and particles. As a leading company for powder synthesis, fluid bed and spouted bed technology, Glatt will provide insights into successful customer projects for particle design, process planning and plant engineering at booth 3-732.

Copyright: Glatt

Copyright: GlattGlatt Particle Design from NANO to MACRO at SOLIDS 2023 – Booth H04-5

As a leader in fluid bed technology and powder synthesis with its own Technology Center in Weimar, Germany, Glatt will highlight integrated concepts in the areas of particle design, process know-how and plant engineering. Glatt experts will be happy to discuss a wide range of topics — from product idea to the industrial manufacture of products and ingredients — in the bulk solids processing industries. Meet our experts at booth H04-5.

Copyright: Glatt

Copyright: GlattWith short time-to-market from process development directly to contract manufacturing

The Glatt Group's customers benefit from bundled expertise in particle design - from the initial feasibility trial, through scale-up, to validation of the production process. Glatt offers suitable solutions for every variant and, if required, also implements customer-specific processes. In this way, new products move more quickly from the development phase to market maturity. (German article)

Copyright: HPCi Media Limited

Copyright: HPCi Media LimitedDrying liquids – Selecting the best technology for nutraceuticals

Both spray drying and fluid bed spray granulation can be used to convert liquid products into bulk materials. The most effective process will often be dictated by the desired properties of the final particles and the specific application. Glatt Ingenieurtechnik has a thorough understanding of both techniques and has a long history of designing fluid bed systems that are tailored to individual customer products.

Copyright: CRU

Copyright: CRUProduct Design for Customized Specialty Fertilizers. Phosphates 27.02.-01.03.2023 in Istanbul

Save the Date: March 1st – 12:00am! Dr. Jens Bergmann, Sales Manager - Process Technology Food, Feed & Fine Chemicals at Glatt Ingenieurtechnik GmbH, will inform about Glatt as partner for particle design and plant manufacturing for functional granules from your product idea to industrial production. Fluid bed technology is the key to environmentally friendly production of effectively acting, abrasion-resistant, easy-to-dose, storage-stable fertilizers.

Copyright: Thomas Müller

Copyright: Thomas MüllerBodo Ramelow, Minister President of the Free State of Thuringia, visits Glatt Ingenieurtechnik

On January 13, 2023, the Prime Minister of Thuringia, Bodo Ramelow, visited us in Weimar's Nordstraße. During the tour of the site, the Minister President was given an impressive insight into our plant technology and the range of services we offer. During a tour of the company buildings, he personally informed himself with some employees about their work tasks in projects. He then paid tribute to our technological expertise and our broad positioning in many industrial sectors, which is certainly unparalleled in Thuringia.

Copyright: Springer Fachmedien Wiesbaden GmbH

Copyright: Springer Fachmedien Wiesbaden GmbHCeramic Raw Materials from the Pulsating Hot Gas Stream

By using Glatt’s innovative powder synthesis technology and the associated spray drying and calcination processes, new opportunities in raw material production have been explored. In this article, the inherent potential of barium strontium cobalt iron oxide (BSCF), doped and coated zirconium dioxide is described.

Copyright: ISTMAG –ISTANBUL MAGAZINE GROUP

Copyright: ISTMAG –ISTANBUL MAGAZINE GROUPOptimization of functional ingredients for improved nutrition by fluid bed and spouted bed technologies

Fluidised bed and spouted bed processes by Glatt offer manufacturers almost unlimited possibilities in terms of optimised particle design and the functionalisation of ingredients, the properties of which can be fine-tuned using spray granulation, agglomeration, microencapsulation and film, lipid and hotmelt coating.

Copyright: Glatt

Copyright: GlattGlatt. Meet the Experts @ 4G127 ● Fi Food Ingredients Europe ● 6-8 Dec 2022 ● Paris ● France

Glatt fluidized bed technologies for sophisticated product design: Added-value ingredients require gentle processes and sustainable packaging. At Fi Europe, particle design, process development and plant engineering specialist Glatt will present innovative solutions to meet these needs.

Copyright: Glatt

Copyright: GlattGlatt and IE Group commissioned to plan the world’s first integrated precision and mycelium fermentation protein plant

Planetary's production facility is designed to be a first of its kind multi-product microbial fermentation facility, able to produce precision fermented compounds, such as proteins and lipids, as well as biomass from mycelium on a commercial scale. Glatt Ingenieurtechnik will plan the process technology systems, including media supply, process control and automation, as well as the safety technology.

Copyright: Hüthig GmbH

Copyright: Hüthig GmbHPowder expertise for demanding tasks – Targeted plant modifications for fluid bed processes

The fluid bed is a technology that, with the right modifications, can be used for a variety of different processes. With the right expertise, individual process steps such as drying, granulation and agglomeration can be combined. (German article by Monika Goslinska, Process Development Manager, Inprotec)

Copyright: Glatt

Copyright: GlattMeet the Glatt experts at 14th University Course Fluidization Technology

Dr. Michael Jacob, Head of the Process Engineering Department at Glatt Ingenieurtechnik GmbH, will give a lecture on "Vacuum drying in fluidized beds". This will be part of the 4-day program around fundamentals and applications in drying, granulation and agglomeration.

Copyright: Glatt

Copyright: GlattGlatt Ingenieurtechnik GmbH in Weimar puts 100 kWp photovoltaic sytsem into operation

The company Glatt Ingenieurtechnik GmbH invested a six-digit sum for the photovoltaic system and uses the generated energy completely as self-consumption and thus reduces the purchase of electrical energy from the public grid as well as the expected high electricity costs.

Copyright: Glatt

Copyright: GlattMeet the Glatt Experts @ SEPAWA Congress ● Stand E723 ● October 26-28, 2022 ● Berlin ● Germany

Meet the Glatt experts and learn how Glatt technologies can improve the performance of your ingredients. Check out the process options of fluid bed and spouted bed technology for value-adding product forms at the annual SEPAWA Congress round about the detergents/cleansers, cosmetics and fragrance industry in Europe.

Copyright: Glatt

Copyright: GlattGlatt Particle Design + Plant Engineering at Powtech 2022

”From Particle Design to the Production of Powders, Granules and Pellets” is Glatt’s motto for POWTECH 2022. Company experts will be available in Hall 3 Booth 3A-101 to discuss the complete workflow from product idea to commercial production. As a leading fluid bed technology company with its own Technology Center in Weimar, Germany, Glatt will be showcasing the interplay between particle design, process know-how and plant engineering.

Glatt selected for Engineering Project for new GMP Biorefinery by NSTDA in Thailand

August 2022 – National Science and Technology Development Agency Thailand (NSTDA) is implementing the Government initiative Thailand 4.0 with regard to strategic biotechnology growth hub at Eastern Economic Corridor of Innovation (EECi) in Thailand. One part of the new BIOPOLIS complex is the GMP Biorefinery Pilot Plant at EECi, for which German engineering company Glatt Ingenieurtechnik was selected to provide the engineering services. The contract between NSTDA and Glatt comprises Conceptual and Basic Design phase for the GMP Biorefinery.

Copyright: Konradin Verlag Robert Kohlhammer GmbH

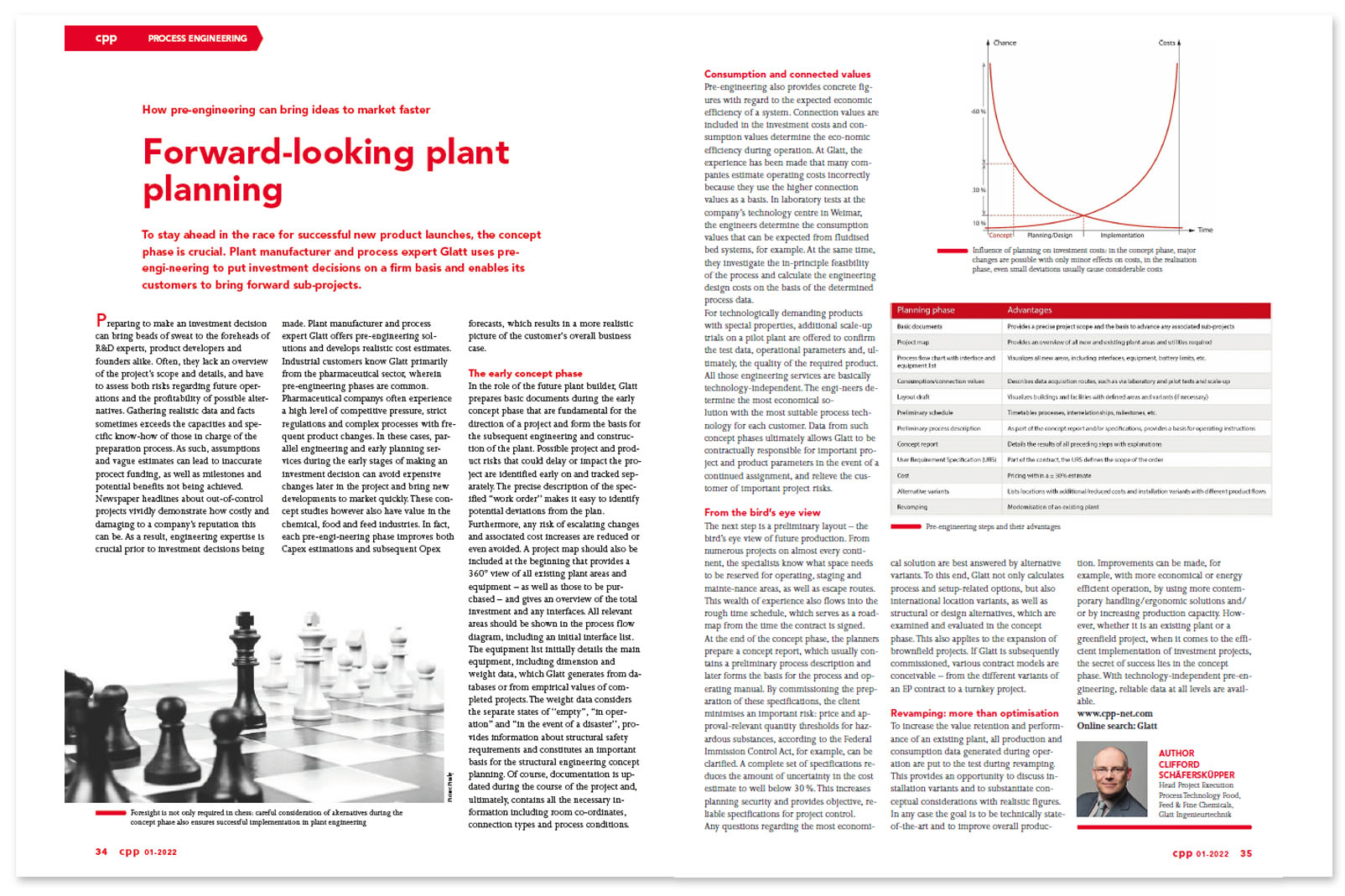

Copyright: Konradin Verlag Robert Kohlhammer GmbHForward-looking plant planning – How pre-engineering can bring ideas to market faster

Being prepared to make an investment decision. Stay ahead in the race for successful new product launches, the concept phase is crucial. Plant manufacturer and process expert Glatt uses pre-engineering to put investment decisions on a firm basis and enables its customers to bring forward sub-projects.

Copyright: Glatt

Copyright: GlattGlatt Particle Design of Catalytic Powders @ Katalytikertagung 2022

'Synthesis of powders in an oscillating process gas: Reactor design and application for catalytic active materials'. The Glatt Powder Synthesis is not only suitable to produce powders but also for the coating of materials. Starting from suspensions, drying, coating and calcination can be done in one step by a core-shell process. Besides the presentation of the technology, the fabrication of photocatalysts as well as oxide materials for the generation of hydrogen will be exemplified.

Copyright: Glatt

Copyright: GlattTechnologies for particle design + plant engineering: Solids 6/R22

Particle sizes from nano to macro: Homogeneous powders and flowable, abrasion-resistant granules and pellets from solid and/or liquid raw materials. Learn more about the process engineering options with processes for drying, granulation, coating, encapsulation and/or calcination. Meet our Glatt particle design and plant engineering experts at Solids from June 22-23, 2022 in Dortmund, Germany at booth 6/R22.

Copyright: Glatt

Copyright: GlattGlatt Particle Design from Nano to Macro @ ceramitec 2022

With their wide range of process options, Glatt technologies provide almost unlimited possibilities for optimum particle design and the functionalization of powders and granules for bioceramics, industrial ceramics, LED applications and batteries for electromobility ... From nanometers to millimeters, Glatt Ingenieurtechnik will be demonstrating its expertise in particle design for grain sizes from nano to macro at this year’s ceramitec. Meet the Glatt experts at the booth C2.409

Copyright: Glatt

Copyright: GlattGlatt lecture at the University of Leeds – Short Cours MICROENCAPSULATION

This course covers the basic science and engineering of microencapsulation across a wide range of applications including the important stages of emulsification control, stability and release property control. Meet our Glatt expert Didier Schons and listen to his lecture "Particle functionalization by core-shell or matrix-encapsulation in fluidized beds from an industrial perspective". University of Leeds - Short Cours MICROENCAPSULATION from 27 to 29 June 2022

Copyright: Glatt

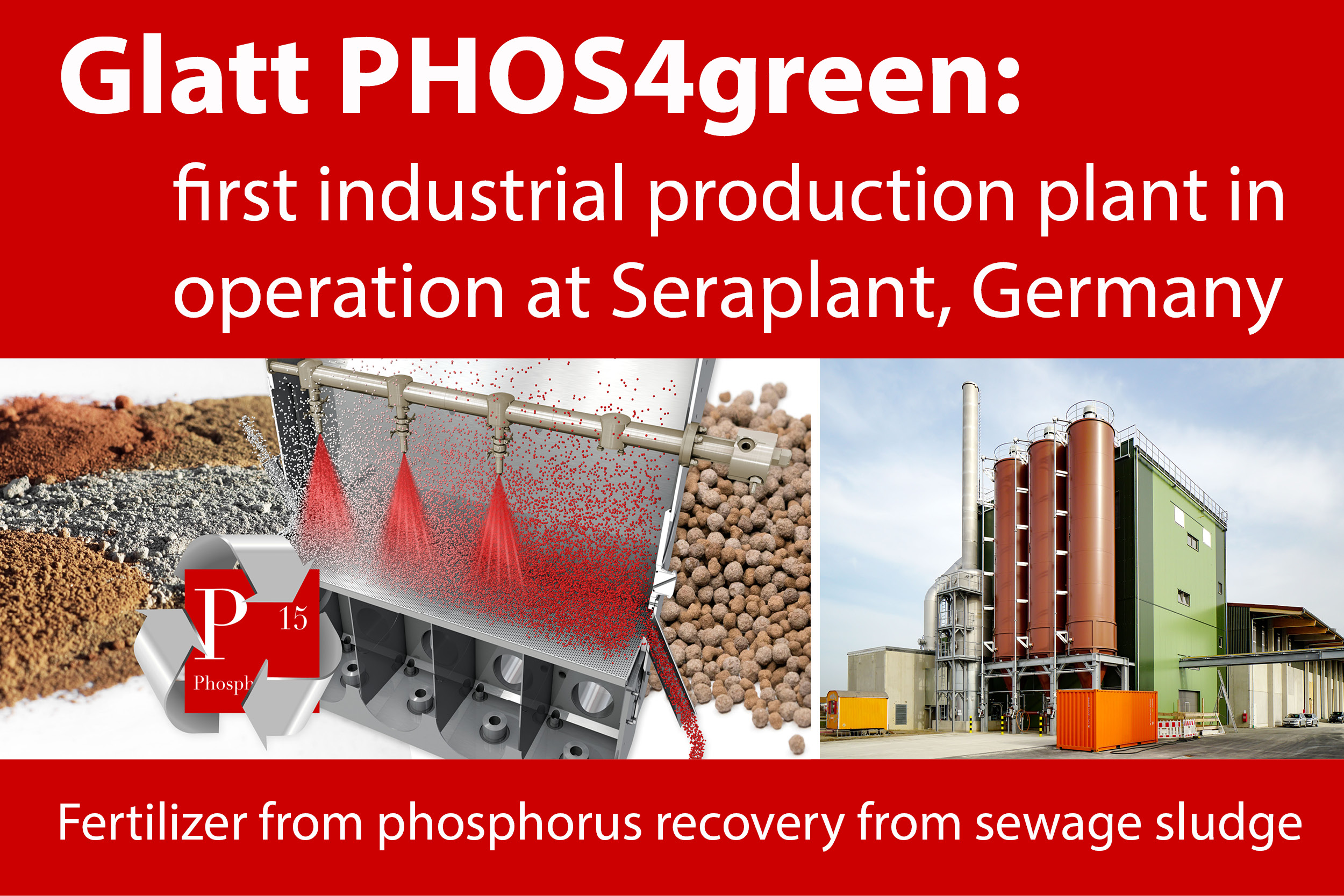

Copyright: GlattGlatt PHOS4green at the IFAT 2022

Glatt Ingenieurtechnik is exhibiting for the first time at IFAT, the world's leading trade fair for environmental technologies in Munich. The company will showcase its patented PHOS4green technology to recover phosphorus from sewage sludge ash and convert it directly into ready-to-use phosphate or compound fertilizers. On booth A4.509, visitors will be able to learn more about this innovative approach that’s already being successfully used at an industrial scale.

Copyright: Glatt

Copyright: GlattParticle Design & Engineering from Nano to Macro at the Chemspec Europe 2022

Meet the Glatt experts at Chemspec Europe on 31.05. - 01.06.2022 for Particle Design & Engineering from Nano to Macro:

Processing of liquids and powders at 40 - 1300 °C: drying, granulation, coating, calcination in ONE process step. Batch and continuous mode. Hotmelt Processing. Solvent Recovery.

High-performance powders, granules and pellets. Homogeneous. Dustfree. Unique. Adjustable properties. Functionalization.

Copyright: Glatt

Copyright: GlattGlatt @ Food & Nutritional Ingredients 2022, Istanbul

Drying and granule formation in only ONE process step. Benefit from Glatt spouted bed and fluid bed technology. Visit us at Food and Nutritional Ingredients from May 25-27, 2022 at the Istanbul Expo Center. You will find the Glatt experts for particle design, process technology and plant engineering in hall 10 at booth D201.

Copyright: PanGlobal Media

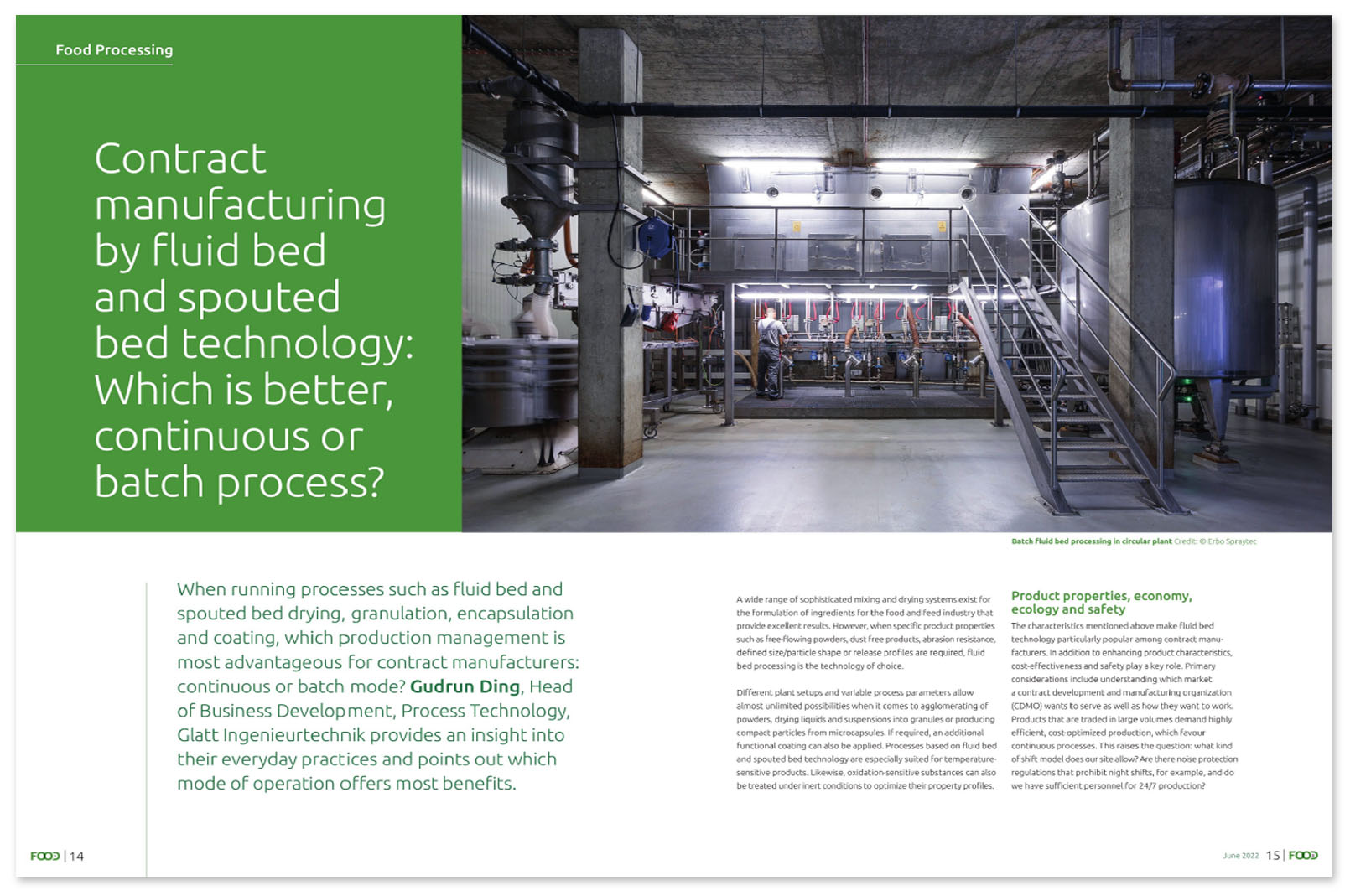

Copyright: PanGlobal MediaContract manufacturing by fluid bed and spouted bed technology: Which is better, continuous or batch process?

When running processes such as fluid bed and spouted bed drying, granulation, encapsulation and coating, which production management is most advantageous for contract manufacturers: continuous or batch mode? Gudrun Ding, Head of Business Development, Process Technology, Glatt Ingenieurtechnik provides an insight into their everyday practices and points out which mode of operation offers most benefits. Glatt + Erbo Spraytec provide an insight into practice

Copyright: Glatt

Copyright: GlattCourse Fluid Beds: Fluidization, Granulation/Coating and Drying

In his lecture on "Fluid bed granulation/coating - equipment design and operations", Didier Schons, Glatt Ingenieurtechnik, will explain these topics, presenting the differences between batchwise and continuous operation, as well as various aspects for particle and product flow. You will learn more about open and closed process gas systems as well as about the premises for the use of multi-purpose plants. The explanations will be illustrated by means of selected case studies.

Copyright: Glatt

Copyright: GlattMeet the Glatt experts at the 24th Microencapsulation Industrial Convention

Find out more about how Glatt, as a plant manufacturer and expert in technologies and processes for particle design, is meeting the current requirements from the powder processing industry. In their presentation "Trends and challenges in fluid bed encapsulation processes", Katja Oppermann and Didier Schons, both Glatt Ingenieurtechnik, will explain which options are opened up by adapted technological concepts.

Copyright: Glatt

Copyright: GlattMeet the Glatt experts at the ChemProTech India 2022

Free-flowing granules and pellets from liquids and powders using innovative fluid bed and spouted bed technology at Booth G12 in Hall 1. With state-of-the-art fluid bed and spouted bed technologies, Glatt offers intelligent particle design to dry, shape and functionalize powders and granules with the desired properties in just one process step, improving their application and handling.

Copyright: Glatt

Copyright: GlattGlatt expands engineering capacity in Cologne, Germany

On 1 March 2022, Glatt Ingenieurtechnik GmbH opened a new branch in Cologne. The new unit will showcase the company’s pharmaceutical, biotechnology and active ingredient plant expertise and represents Glatt’s first location in North Rhine-Westphalia. The decision to expand was based on a positive market outlook in the field of pharmaceutical engineering and excellent capacity utilization.

Copyright: Glatt

Copyright: GlattGlatt expands technology center with new laboratory plant for powder synthesis

In January 2022, plant manufacturer and process expert, Glatt Ingenieurtechnik, expanded its powder synthesis capacity at the company’s technology center in Weimar. The newly installed system ensures a homogenous process temperature throughout the entire length of the ProAPP® 80 HT reactor or the targeted adjustment of temperature gradients. This allows different process steps to be combined.

Glatt Ingenieurtechnik commissioned to plan new BioCampus in Straubing

Weimar, Germany, March 2022: Glatt Ingenieurtechnik GmbH (Weimar, Germany) will be responsible for the Basic Engineering of the process technology for the multipurpose BioCampus MultiPilot (BMP) plant on behalf of BioCampus Straubing GmbH. Here, at the Straubing-Sand port, customers will be able to develop, test, optimize and scale-up industrial biotechnology processes, validate their economic viability and manufacture samples.

Copyright: ISTMAG –ISTANBUL MAGAZINE GROUP

Copyright: ISTMAG –ISTANBUL MAGAZINE GROUPSpray agglomerating plant-based milk alternatives for optimised product properties

Powdery substances often cause problems during dosing, filling and transport because of their high dust content and poor flowability. Low solubilities and dispersing properties also impair the application of the end product. With the help of fluidised bed spray agglomeration, the size distribution and structure of difficult-to-process particles can be specifically adjusted and improved.

Copyright: Palladian Publications Ltd

Copyright: Palladian Publications LtdGrowing the German phosphate industry

Part 1 of this article will highlight a scientific study on the long-term bioavailability of the nutrients in different phosphorus fertilizers. Part 2 will provide a report on the first German production plant and present a research project in the Frankfurt Rhine-Main area. Jan Kirchhof, Glatt Ingenieurtechnik GmbH, Germany, reports on a laboratory experiment with phosphorus fertilizers and two current projects.

Copyright: Hüthig GmbH

Copyright: Hüthig GmbHOutsourcing of the production – Trust in competent partners

How the Glatt Group implements contract manufacturing with expertise and innovative solutions. There are many reasons for outsourcing production - minimizing one's own risks or a lack of expertise in alternative technologies are just two of them. But what to look for when looking for a contract manufacturing partner?

Copyright: SIGWERB GmbH

Copyright: SIGWERB GmbHA spirit of optimism between batch and continuous production

The concept of continuous production is captivating. No longer batch by batch - instead, for example, a liquid product can simply be tapped at any time. It is therefore surprising that "continuous manufacturing" did not already triumphantly conquer chemical and pharmaceutical production five or ten years ago. In the meantime, however, there are a whole series of forward-looking examples.

Copyright: PanGlobal Media

Copyright: PanGlobal MediaFood, feed and pet nutrition: a convergence of industries

Food mega-trends such as added health benefits, natural raw materials and sustainable sourcing are becoming increasingly important for another large target group: animals. Functional or active ingredients such as vitamins or probiotics, enzymes, yeasts, essential oils, proteins or microorganisms must be optimised and adapted for industrial processes, storage and feeding conditions. Glatt Ingenieurtechnik, a leading global plant manufacturer and process expert, offers feed producers process development, technology and plant expertise from a single source.

Copyright: Vereinigte Fachverlage

Copyright: Vereinigte FachverlageClosing the Loop – Phosphorus Recovery on an Industrial Scale

The first fertilizers produced using the PHOS4green process have been available on the German market since June. The technology, which breaks down the phosphorus contained in sewage sludge ash and makes it reavailable in marketable end products, was developed by plant engineering and process expert Glatt Ingenieurtechnik in cooperation with fertilizer specialist Seraplant.

Copyright: Glatt

Copyright: GlattParticle Design + Plant Engineering at the Food Ingredients Europe 2021

Are you interested in efficient possibilities in product design with natural ingredients for sports nutrition, dietary supplements and beverage applications? Then you’ve come to the right place with the Glatt experts for process development and plant engineering. Visit us at the Food Ingredients Europe in Frankfurt at the booth 31K62. We will be happy to explain how you can optimize the product properties of your ingredients.

Copyright: Glatt

Copyright: GlattParticle Design + Plant Engineering at the PCH Meetings 2021

Check out the unique supply chain from the first product idea to an efficient production from one single source: Technology transfer, plant design and factory engineering for the development, enhancement and production of functional powders, granules and pellets. Meet the Glatt experts for particle design and plant engineering at the PCH Meetings from 24-25 November 2021 in Lyon, France.

Copyright: Glatt

Copyright: GlattMeet the Glatt Experts for Particle Design at Les Rendez-Vous Carnot 2021

Upgrade your products by enhancing particle properties and adding functionality. Drying and granule formation for your products and ingredients in only one process step. Meet the Glatt experts for particle design at Les Rendez-Vous Carnot 2021, 17. - 18. November, Cité - Centre des Congrès – Lyon - France and discuss your product ideas.

Copyright: HPCi Media Limited

Copyright: HPCi Media LimitedHow to Tame Recalcitrant Ingredients with Technological Processes

Plant-based functional ingredients behave differently than manufacturers of nutraceuticals and cosmetic products would like. Innovative processes such as double microencapsulation can help them to overcome bioavailability and solubility challenges.

Copyright: Glatt

Copyright: GlattOptimizing the product properties of your ingredients

Drying and granule formation for your ingredients in only one process step. Meet the Glatt experts at the Vitafoods in Geneva. 5 - 7 October 2021 at booth K230 to find innovative technologies to enhance your ingredients: better bioavailability, flowability and dust-free properties, improved solubility, tabletable agglomerates, functional coating, controlled release of active ingredients, drying of solvent-based products, microencapsulation of volatile and sensitive substances ...

Copyright: Glatt

Copyright: GlattParticle Design & Engineering from Nano to Macro

Meet the Glatt experts at Chemspec DIGITAL 2021 on September 29 - 30, 2021 for Particle Design & Engineering from Nano to Macro:

Processing of liquids and powders at 40 - 1300 °C: drying, granulation, coating, calcination in ONE process step. Batch and continuous mode. Hotmelt Processing. Solvent Recovery.

High-performance powders, granules and pellets. Homogeneous. Dustfree. Unique. Adjustable properties. Functionalization.

Copyright: Glatt

Copyright: GlattNew fluid bed options for solvent-based processes and products requiring Kosher and Halal conditions

Glatt has expanded its range of services and capacities at the company’s Technology Centre in Weimar for trials and sample development. A new fluid bed granulator and coater for innovative solvent-based processes has recently become available. In addition to the capacity expansion, the existing plant can also now accommodate continuous spray granulation processes.

Copyright: Glatt

Copyright: GlattGlatt PHOS4green Experts at the German Phosphorus Platform 2021

Under the topic "Phosphorus Recyclates - Not for the garbage can!?" this year's forum event took place in Frankfurt am Main on September 9, 2021. The experts of Glatt PHOS4green thank you for the interest in the presentation of Jan Kirchhof, Glatt Ingenieurtechnik and Henning Schmidt, Seraplant on phosphorus recovery from sewage sludge ash and its conversion into ready-to-use standard fertilizers.

Meet the Glatt experts at 13th University Course Fluidization Technology

Dr. Michael Jacob, Head of the Process Engineering Department at Glatt Ingenieurtechnik GmbH, will give a lecture on "Vacuum drying in fluidized beds". This will be part of the 4-day program around fundamentals and applications in drying, granulation and agglomeration.

Copyright: Springer Fachmedien Wiesbaden GmbH

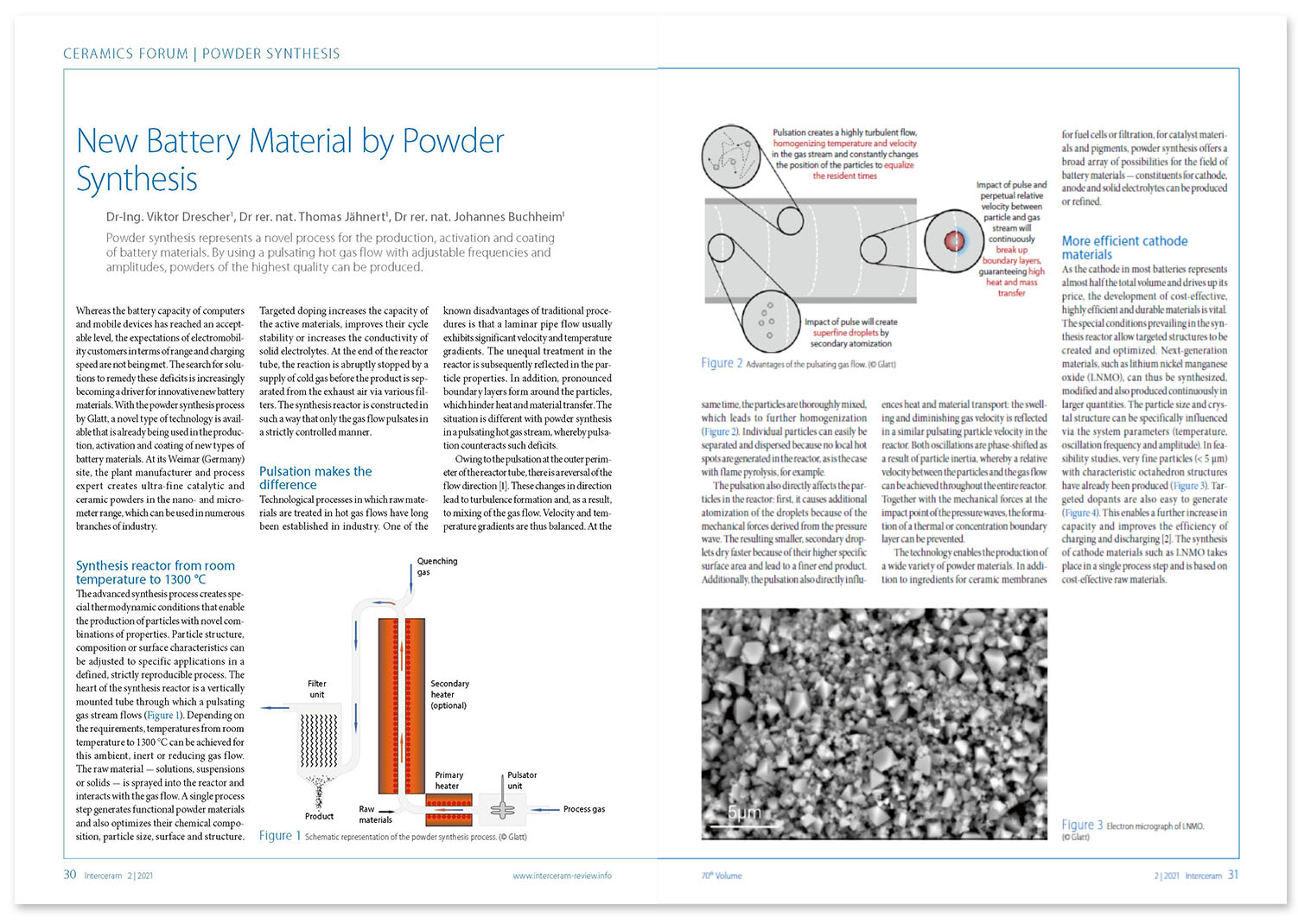

Copyright: Springer Fachmedien Wiesbaden GmbHNew Battery Material by Powder Synthesis

Powder synthesis represents a novel process for the production, activation and coating of battery materials. By using a pulsating hot gas flow with adjustable frequencies and amplitudes, powders of the highest quality can be produced. Solutions to address current shortcomings as innovation drivers for new battery materials.

Copyright: Glatt

Copyright: GlattGlatt synthesis reactor ProAPP® Lab as the world‘s first flameles high-temperature powder synthesis plant at Fraunhofer IKTS for high-purity oxidic nanopowders

At its Hermsdorf site, the Fraunhofer Institute for Ceramic Technologies and Systems IKTS creates high-performance oxide ceramics for medical technology and optical components. The world's first Glatt synthesis reactor for temperatures up to 1300°C was recently put into operation there, with the powder synthesis process based, for the first time, on a flameless concept with pulsating gas flow.

Copyright: Glatt

Copyright: GlattMeet the Glatt experts at the abonocare® online conference

At the 2nd Conference of abonocare® - sustainable nutrient recycling from organic residues Dr. Michael Jacob will give a lecture on 'Fertilizer production from N- and P-rich recyclates using fluid bed spray granulation'. He will show product examples and present an industrial-scale reference plant at Seraplant in Haldensleben, Germany.

Glatt Ingenieurtechnik honored as an outstanding company with the East German Business Forum Award

On June 14, 2021, the VORSPRUNG business award was presented for the second time. This year, the business prize 'VORSPRUNG' went to the Weimar company Glatt Ingenieurtechnik GmbH, along with 4 other prize winners from other federal states. The Thuringian Minister of Economics, Wolfgang Tiefensee, acted as laudator for the prize winner.

Copyright: Glatt

Copyright: GlattGlatt PHOS4green: first production plant for fertilizer from sewage sludge in operation at Seraplant

Production starts at first German PHOS4green plant for recycled fertilizers. Residue-free production of ready-to-use fertilizer from phosphate-containing sewage sludge ash is now possible, thanks to plant manufacturer and process expert Glatt Ingenieurtechnik, and fertilizer specialist Seraplant. The official commissioning on May 31, 2021, was attended by Prof Dr Armin Willingmann, Saxony-Anhalt's Minister for Economics, Science and Digitalization.

Copyright: Glatt

Copyright: GlattPHOS4green to be presented at the Sewage Sludge Meeting in Sweden, June, 2-3 2021

Save the date to get the lesson!

Sewage sludge treatment and recycling is also an important topic for Swedish municipalities.

Under the organization of Envisys AB, a technical meeting on sewage sludge will be held in Helsingborg, Sweden. Jan Kirchhof, Senior Sales Manager Process & Plant Engineering, Glatt Ingenieurtechnik GmbH, will inform about a PHOS4green plant for the production of fertilizer from sewage sludge ash.

Copyright: Glatt

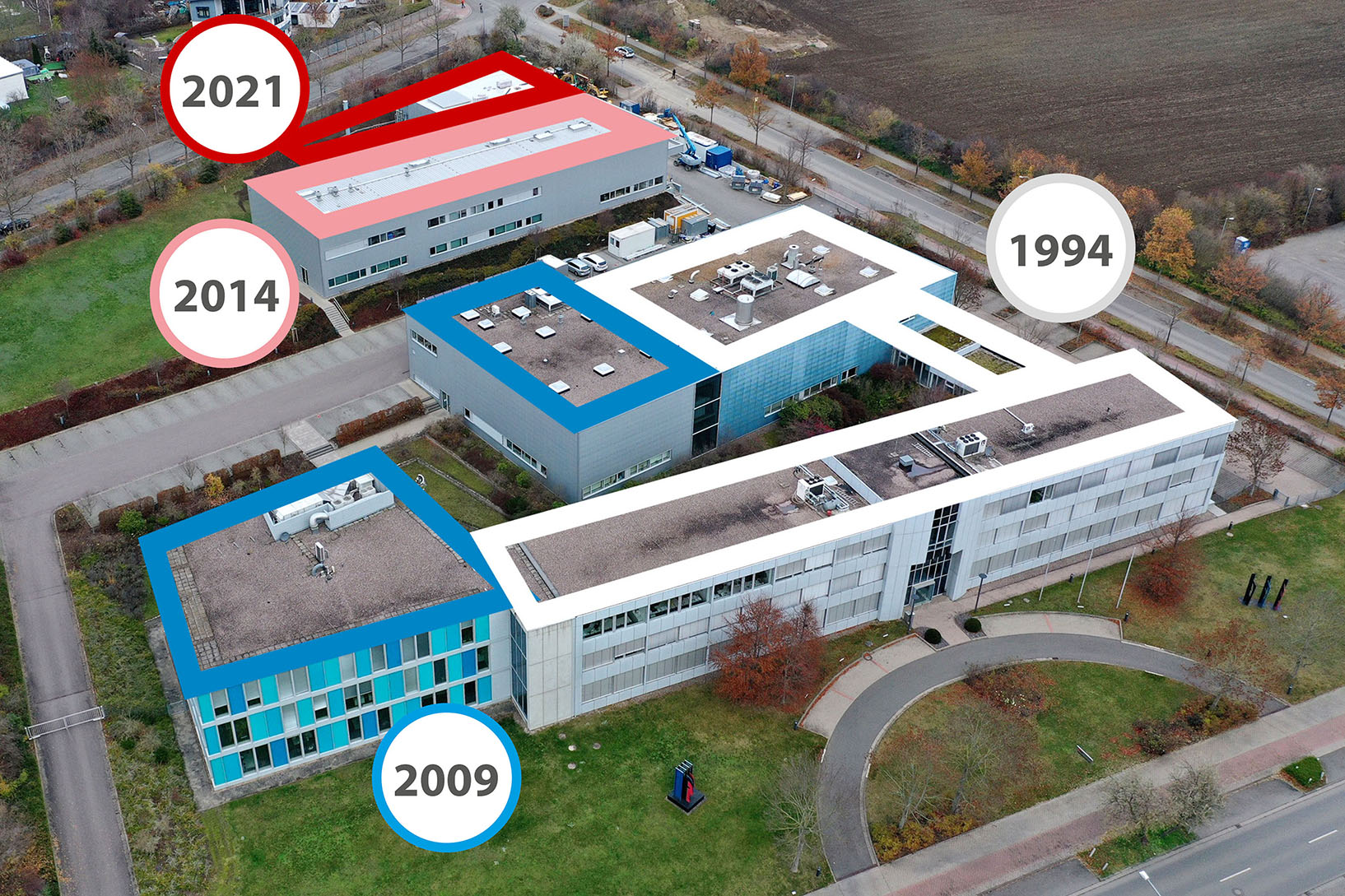

Copyright: GlattGlatt Ingenieurtechnik celebrates continued business success with third expansion of its Technology Center

New services, capacities, employees: plant engineering expert Glatt Ingenieurtechnik marks its 30th anniversary with an investment in the future of its headquarters

From vitamins in animal feed and enzymes in detergents to powder materials for high-performance batteries, Glatt, the Germany-based plant manufacturer and process expert, is working on all of these in close cooperation with renowned research companies. In spring 2021, Glatt will expand its technology center in Weimar for the third time in twelve years.

Join the Glatt Webinar on PHOS4green at the Phosphates Virtual Conference 2021

Save the date - Join the Glatt Webinar: March 24, 2021 - 5.10 pm

Jan Kirchhof, Senior Sales Manager Process & Plant Engineering, Glatt Ingenieurtechnik GmbH, will inform about a PHOS4green plant for the production of fertilizer from sewage sludge ash. At the Haldensleben site in Germany a project for an industrial-scale production plant is already being implemented. The location, the products to be manufactured and their recipes as well as the envisaged production capacities determine the economic efficiency.

Meet the Glatt experts at the Virtual ChemTECH World.IE 2021

Come and check out the innovative fluid bed and spouted bed technologies for granules and pellets!

Glatt welcomes you to visit the Glatt Dashboard and interact with experts to understand what we can do for your ingredients like fertilizers, crop protection agents, salts, polymers, seeds, phosphonates, enzymes, essential oils, fragrances, surfactants, detergents, cleaning agents, colour pigments, ceramics, catalysts, minerals, trace elements, acids, diamonds, and so much more to optimize the desired physical properties and / or to protect sensitive, active and volatile substances.

PHOS4green – Implementation of a Plant for the Production of 60,000 t/a of Fertilizer from Sewage Sludge Ash at Haldensleben

PHOS4green – Implementation of a Plant for the Production of 60,000 t/a of Fertilizer from Sewage Sludge Ash at SERAPLANT Gmbh in Haldensleben, Germany.

Copyright: Innovations in Food Technology

Copyright: Innovations in Food TechnologyFluid bed and spouted bed technologies – Optimising functional ingredients for enhanced nutrition

Fluidised bed and spouted bed processes by Glatt offer manufacturers almost unlimited possibilities in terms of optimised particle design and the functionalisation of ingredients, the properties of which can be fine-tuned using spray granulation, agglomeration, microencapsulation and coating.

Copyright: B5 S.r.l., Italy

Copyright: B5 S.r.l., ItalyThe Gentle Processing of Highly Volatile Oils

Sensitive raw materials, especially those that are volatile or of natural origin, require particularly gentle process conditions. Spray granulation, spray coating and (micro)encapsulation procedures have proven to be methods of choice, as they enable high yields, low temperatures and bespoke properties.

Copyright: Verlag für chemische Industrie H. Ziolkowsky GmbH

Copyright: Verlag für chemische Industrie H. Ziolkowsky GmbHProcess Technologies to Optimize Detergent Manufacturing

How can cleaning agents components be produced in a more environmentally friendly and effective way? With fluid bed and spouted bed technologies, plant manufacturer and process expert, Glatt Ingenieurtechnik, offers modern, established solutions.

Meet the Glatt PHOS4green experts at the 3rd Berliner Klärschlamm-Konferenz

In the presentation on "PHOS4green - Implementation of a plant for the production of 60,000 t/a fertilizer from sewage sludge ashes at the Haldensleben site", Jan Kirchhof, Glatt Ingenieurtechnik GmbH and Torsten Brumme, Seraplant GmbH will present the innovative PHOS4green process, with which the essential and sought-after nutrient phosphorus can be recovered from sewage sludge ashes and used for new phosphate or compound fertilizers.

Copyright: Glatt

Copyright: GlattGlatt builds demonstration plant for heavy metal separation from sewage sludge ash in the Rhine-Main region

How can waste management companies in the Rhine-Main economic region join forces and make phosphorus recyclable for the nutrient cycle, as required by law from 2029? This question is being addressed by the nine players in the RePhoRM joint project. Glatt is contributing its expertise to two subprojects: the planning and construction of a container plant in Industriepark Höchst and the studies on spray granulation of purified secondary phosphorus.

From nano to micro: Register fro free and join the webinar @ Virtual Process Show 8-11 Sep 2020

From nano to micro –

How to generate narrow PSD spherical particles in one step.

Learn about the generation and core-shell-coating of powder materials with new, previously unattained properties. Long-term stability for battery materials through precise, even coating of anode and cathode materials.

Unique new optical effects and maximum protection for paint and coating pigments. Reduced material quantity by core-shell-coated structures for catalytically active powders.

Glatt. Meet the Experts @ Virtual Process Show 8-11 Sep 2020

Trade fairs are postponed, conferences cancelled, travel restricted. Experience networking and the typical trade fair feeling digitally. So we are going on a new path. Visit us from 8 to 11 September 2020 at the Virtual Process Show – the new online trade fair for process and production technology in chemistry, biotech, pharmaceuticals, food and beverages. Register for free and meet the Glatt Experts in the live chat!

Copyright: MDPI

Copyright: MDPIPulsed Multiphase Flows—Numerical Investigation of Particle Dynamics in Pulsating Gas–Solid Flows at Elevated Temperatures

Although the benefits of pulsating multiphase flows and the concomitant opportunity to intensify heat and mass transfer processes for, e.g., drying, extraction or chemical reactions have been known for some time, the industrial implementation is still limited. This is particularly due to the lack of understanding of basic influencing factors, such as amplitude and frequency of the pulsating flow and the resulting particle dynamics. The pulsation generates oscillation of velocity, pressure, and temperature, intensifying the heat and mass transfer by a factor of up to five compared to stationary gas flow

Copyright: Glatt

Copyright: GlattWe are taking care – COVID-19 pandemic

Dear customers, partners and followers

The current situation is very special and challenging for all of us globally. At Glatt we continuously follow and comply with the recommendations by the governmental health authorities on how to conduct our business during the COVID -19 pandemic.

We are taking care ...

Meet the PHOS4green experts at the 1st Abonocare Conference 2020

Come and check out the innovative PHOS4green technology for fertilizer production out of phosphorus recyclates from sewage sludge ashes! Benefit from the information about this phosphorus recycling technology given by Jan Kirchhof, Glatt, in his lecture 'PHOS4green Hochleistungsdünger aus Klärschlammaschen' (PHOS4green: High-performance fertilizer from sewage sludge ashes)

Glatt

GlattGlatt. Meet the Experts @ booth 12D018 ● PRODEXPO ● 10-14 Feb 2020 ● Moscow ● Russia

Innovative Process Technologies for Customized Functional Ingredients and Beverage Powder Mixes: At the 27th International Exhibition for Food, Beverages, Food Raw Materials in Moscow, Glatt will present innovative fluidized bed and spouted bed technologies to dry, agglomerate, granulate and particle coat various ingredients for sophisticated applications. These ingredients may require specific particle sizes or shapes, optimum solubility, compressibility or the functional protection provided by active ingredients or improved stability via protective coatings.

Copyright: Göller Verlag

Copyright: Göller VerlagGlatt Powder Synthesis – Pioneering Process for Groundbreaking Particle Synthesis

Future materials such as high-energy and safe battery components, more economical membranes, orthopedic ceramics, functional additives or high-performance pigments must provide more than the current properties of existing material components. A common issue within each of these applications is the high levels of powder performance that are required. Therefore, completely new products or novel innovations require powder materials that must first be developed and then manufactured in the necessary quantities.

Copyright: EC PRESSE

Copyright: EC PRESSETechnologies à lit fluidisé / Fluid bed and spouted bed technology

Powdery substances often cause problems during dosing, filling and transport because of their high dust content and poor flowability. Low solubilities and dispersing properties also impair the application of the end product. With the help of fluidised bed spray agglomeration, the size distribution and structure of difficult-to-process particles can be specifically adjusted and improved.

Copyright: Innovations in Food Technology

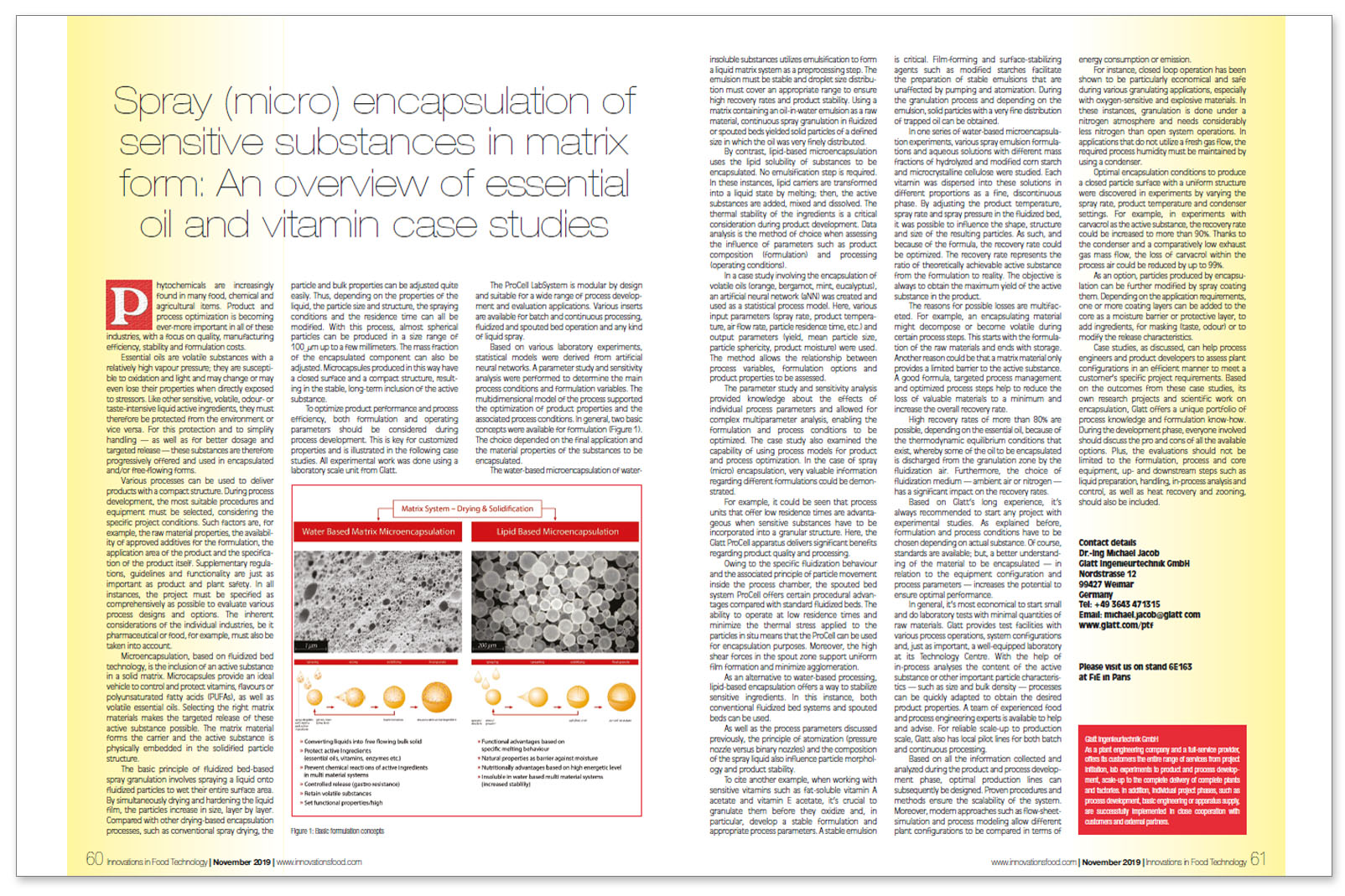

Copyright: Innovations in Food TechnologySpray (micro)encapsulation of sensitive substances in matrix form – An overview of essential oil and vitamin case studies

Phytochemicals are increasingly found in many food, chemical and agricultural items. Product and process optimization is becoming ever-more important in all of these industries, with a focus on quality, manufacturing efficiency, stability and formulation costs. Various processes can be used to deliver products with a compact structure. During process development, the most suitable procedures and equipment must be selected, considering the specific project conditions. Case studies, as discussed, can help process engineers and product developers to assess plant configurations in an efficient manner to meet a customer’s specific project requirements.

Copyright: Glatt

Copyright: GlattUnique German Fertiliser Production Plant Celebrates Roofing Ceremony

Seraplant and Glatt Ingenieurtechnik have jointly developed an innovative technology for residue-free production of phosphate-containing fertiliser granulates from sewage sludge ash.

Fertiliser manufacturer Seraplant from Haldensleben, Germany, recently celebrated the roofing ceremony at a production plant for phosphate-containing single and complex fertilisers for agriculture and forestry use.

Copyright: TRMG Ltd.

Copyright: TRMG Ltd.Improved performance for crop protection products

Plant protection products, be they herbicides or fungicides, must be dust-free, free-flowing, stable, safe to handle and provide good redispersibility properties. In the future, it will also be important to tailor their effectiveness to deal with particular hazards or pests, and increase tolerance to extreme weather conditions.

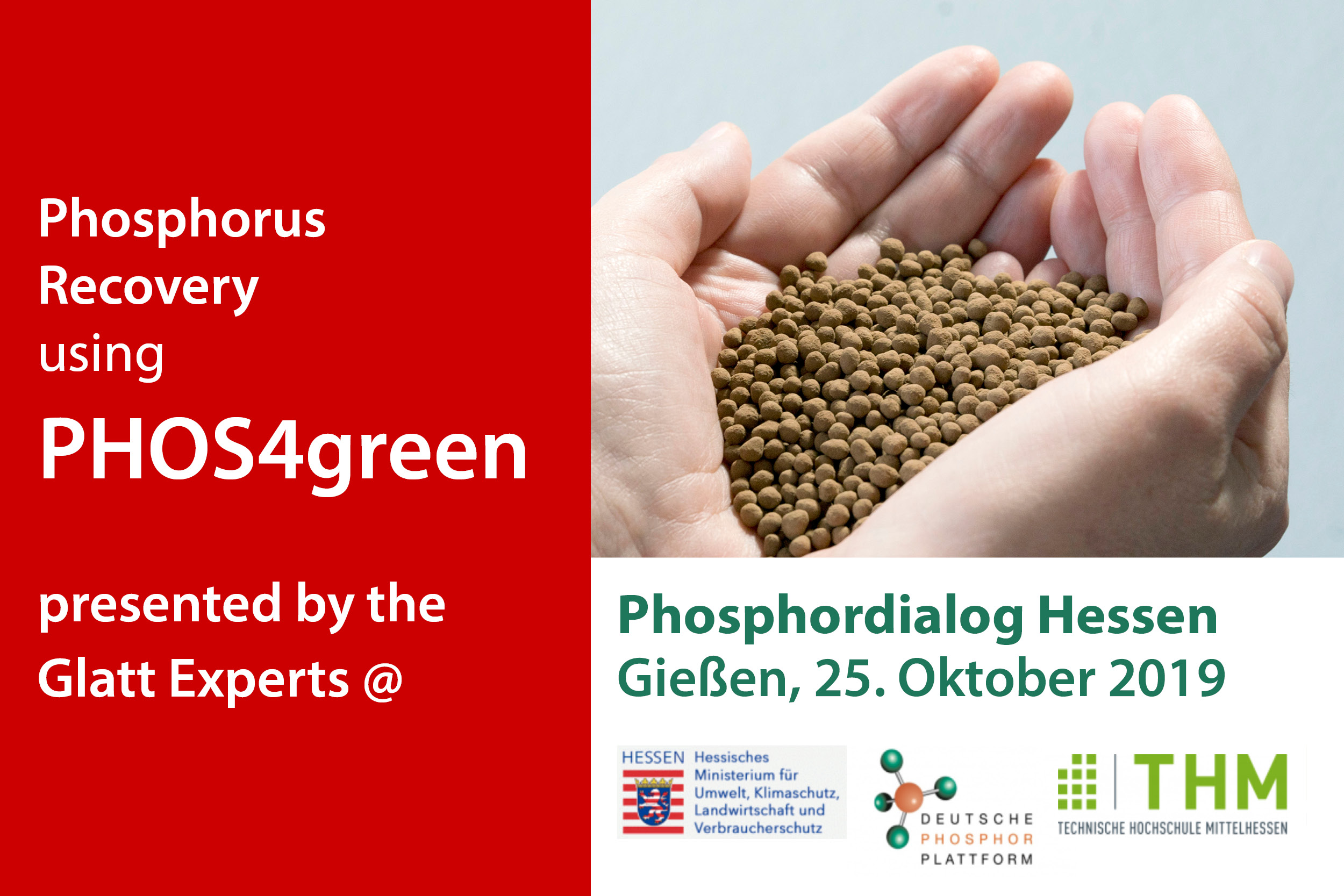

PHOS4green presented at the Phosphorus Dialogue Hesse 2019

On 25.10.2019, another phosphorus dialogue was held by the Hessian Ministry of the Environment, the THM and the DPP in Giessen to inform decision-makers as well as those involved in the process of phosphorus recovery on the topic. Jan Kirchhof, Glatt, presented PHOS4green as a solution for phosphorus recovery from sewage sludge ash and its residue-free conversion into commercially available standard fertilizers.

Copyright: ECS

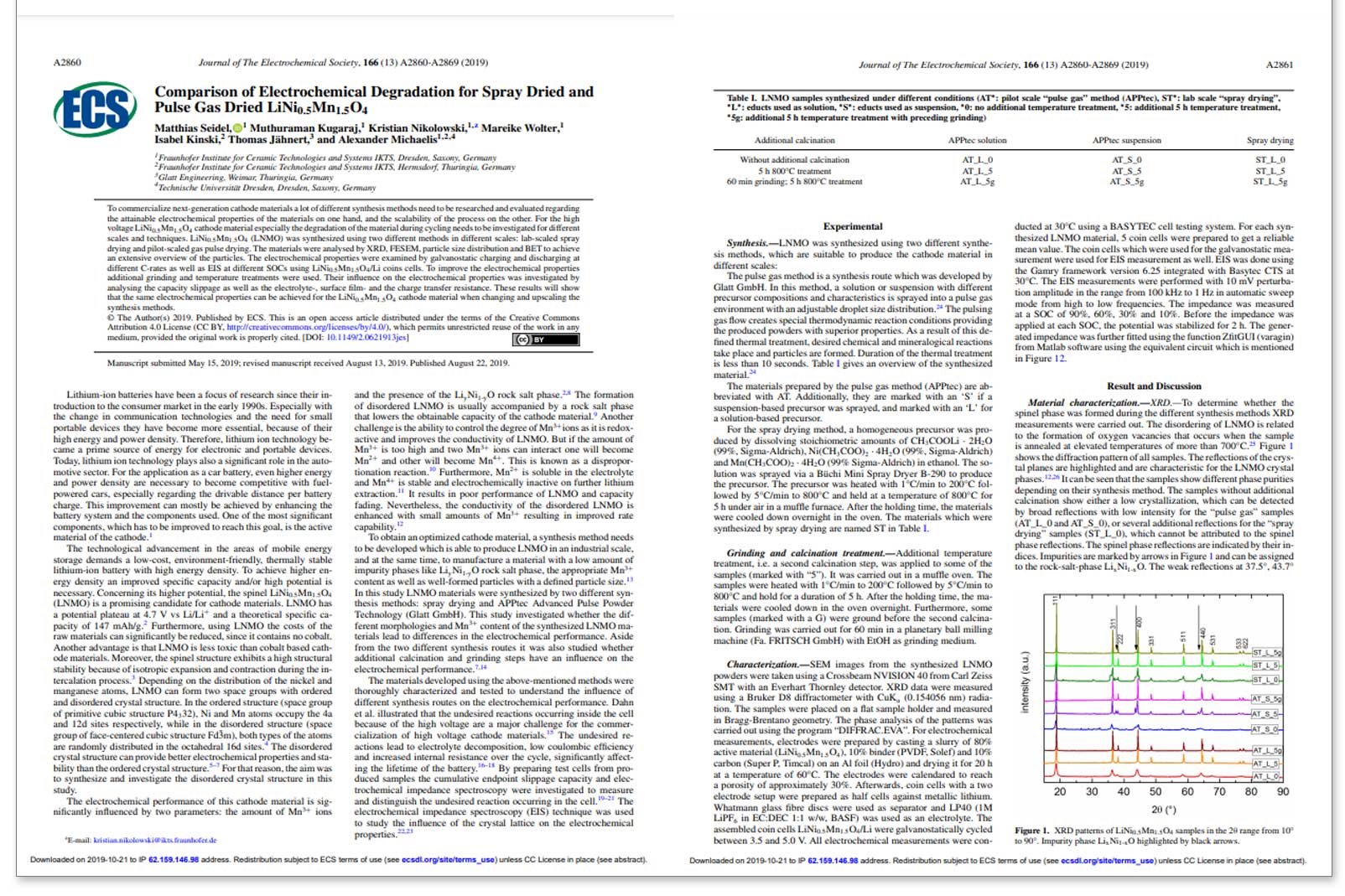

Copyright: ECSComparison of Electrochemical Degradation for Spray Dried and Pulse Gas Dried LiNi0.5Mn1.5O4

To commercialize next-generation cathode materials a lot of different synthesis methods need to be researched and evaluated regarding the attainable electrochemical properties of the materials on one hand, and the scalability of the process on the other. For the high voltage LiNi0.5Mn1.5O4 cathode material especially the degradation of the material during cycling needs to be investigated for different scales and techniques. LiNi0.5Mn1.5O4 (LNMO) was synthesized using two different methods in different scales: lab-scaled spray drying and pilot-scaled gas pulse drying.

Glatt

GlattGlatt. Meet the Experts @ 6E163 ● Fi Food Ingredients Europe ● 3-5 Dec 2019 ● Paris ● France

Glatt fluidized bed technologies for sophisticated product design: Added-value ingredients require gentle processes and sustainable packaging. At Fi Europe, plant engineering and process development specialist Glatt will present innovative solutions to meet these needs.

Copyright: TEKNOSCIENZE Srl

Copyright: TEKNOSCIENZE SrlWhy contract manufacturing is both critical and crucial

For decades, large companies have outsourced production capabilities, thus driving globalisation –but also contributing to the decline of domestic industries. Digitalization, however, means it makes sense for more and more well-known global players to relocate production back to Europe. Contract manufacturing, for example, gives an idea of where this journey can take us.

Meet the PHOS4green experts at the 5th P-Rück-Kongress 2019

The Ministry of the Environment Baden-Württemberg and the DWA Regional Association Baden-Württemberg organize the 5th Congress PHOSPHOR - A CRITICAL RAW MATERIAL WITH A FUTURE

Follow the presentation of Jan Kirchhof, Senior Sales Manager Process & Plant Engineering, Glatt Ingenieurtechnik GmbH, and learn more about the innovativation of PHOS4green technology for the fertilizer production with phosphorus recyclates out of sewage sludge ashes!

PHOS4green presented at the Nutrient Platform 2019 in Utrecht, NL

Frits Elferink, NBP Handelsbureau B.V., presented the Glatt PHOS4green technology as an innovative solution for phosphorus recovery from sewage sludge ashes and its residue-free conversion into ready-to-use, commercially available standard phosphorus fertilizers. The Nutrient Platform is a cross-sectoral network of Dutch organizations that believe in a pragmatic approach towards nutrient scarcity. By recovering phosphorus from the ‘waste’ streams and turning it into valuable new products, not only the environment is improved but also the phosphorus cycle is closed.

Meet the Glatt Experts @ 13. Schüttgut-Forum 2019 ● 19-20 November ● Würzburg, Germany

How do you produce dust-free granules and pellets from powders and liquids? In the fluid bed. In a single process step. Didier Schons, Area Sales Manager, Process Technology Food, Feed & Fine Chemicals at Glatt Ingenieurtechnik Weimar, explains how this works.

Meet the Glatt Experts @ 11th University Course Fluidization Technology ● November 07-07, 2019 ● Hamburg, Germany

Dr. Michael Jacob, Head of the Process Engineering Department at Glatt Ingenieurtechnik GmbH, will give a lecture on "Vacuum drying in fluidized beds". This will be part of the 4-day program around fundamentals and applications in drying, granulation and agglomeration.

Meet the Glatt Experts @ SEPAWA Congress ● Stand C529 ● October 23-25, 2019 ● Berlin ● Germany

Dipl.-Ing. Katja Oppermann, Glatt Ingenieurtechnik, Weimar, will give a lecture on "Process options of fluid bed technology for value-adding product forms" at the SEPAWA Congress round about the detergents/cleansers, cosmetics and fragrance industry in Europe.

Meet the Glatt Experts @ ProPack India 2019 ● Booth P1 ● 22-24 October ● Mumbai ● India

Sophisticated product design with Glatt fluid bed and spouted bed technologies @ ProPak 2019, booth P1: Added-value ingredients and active substances require gentle processes. Glatt’s laboratory plant enables the small-scale production and testing of innovative product ideas.

Meet the PHOS4green Experts at the VDI Technical Conference Sewage Sludge Treatment 2019 in Mainz, Germany

The VDI conference "Sewage Sludge Treatment" will take place for the tenth time this year. Discover phosphorus recovery with PHOS4green and check out this innovative technology for fertilizer production out of phosphorus recyclates from sewage sludge ashes! Benefit from the information about this phosphorus recycling technology given by Dr. Thomas Jähnert, Glatt, in his lecture 'PHOS4green Hochleistungsdünger aus Klärschlammaschen' (PHOS4green: High-performance fertilizer from sewage sludge ashes)

Meet the Glatt Experts @ NutriForm Business Days 2019 ● 11-12 September ● Saint Raphaël (Var), France

Particle design and drying in just one process step using fluidized bed technology. Perfect determination of particle properties, functionalization and protection of active, volatile and sensitive substances. Listen to the lecture on 'Functionalization of food supplements'.

PHOS4green presented @ Sewage Sludge Technical Forum 2019 in Berching, Germany

In some regions, the departure from agricultural sewage sludge use is coming faster than the sewage sludge ordinance requires. This was demonstrated at the sewage sludge specialist forum held by the Huber company in Berching, where a good 300 participants discussed concepts for sewage sludge utilization, phosphorus recovery and inter-municipal cooperation.

Jan Kirchhof, Glatt, presented PHOS4green as a solution for phosphorus recovery from sewage sludge ash and its residue-free conversion into commercially available standard fertilizers.

Meet the Glatt Experts @ EuroDrying’ 2019 ● 10-12 July ● Turin, Italy

At the 7th European Drying Conference Dr. Michael Jacob, Head of Process Engineering, Glatt Process Technology Food, Feed & Fine Chemicals, will give a lecture about "Process analytical technologies for inline control of fluidized bed agglomeration".

Glatt Ingenieurtechnik: Pioneer in the East and in cutting-edge research

Glatt Ingenieurtechnik: Pioneer in the East and in cutting-edge research

The plant engineering company Glatt Ingenieurtechnik is one of the most innovative companies in the East and conducts research into the materials and production processes of the future. (German article)

Copyright: Konradin-Verlag Robert Kohlhammer GmbH

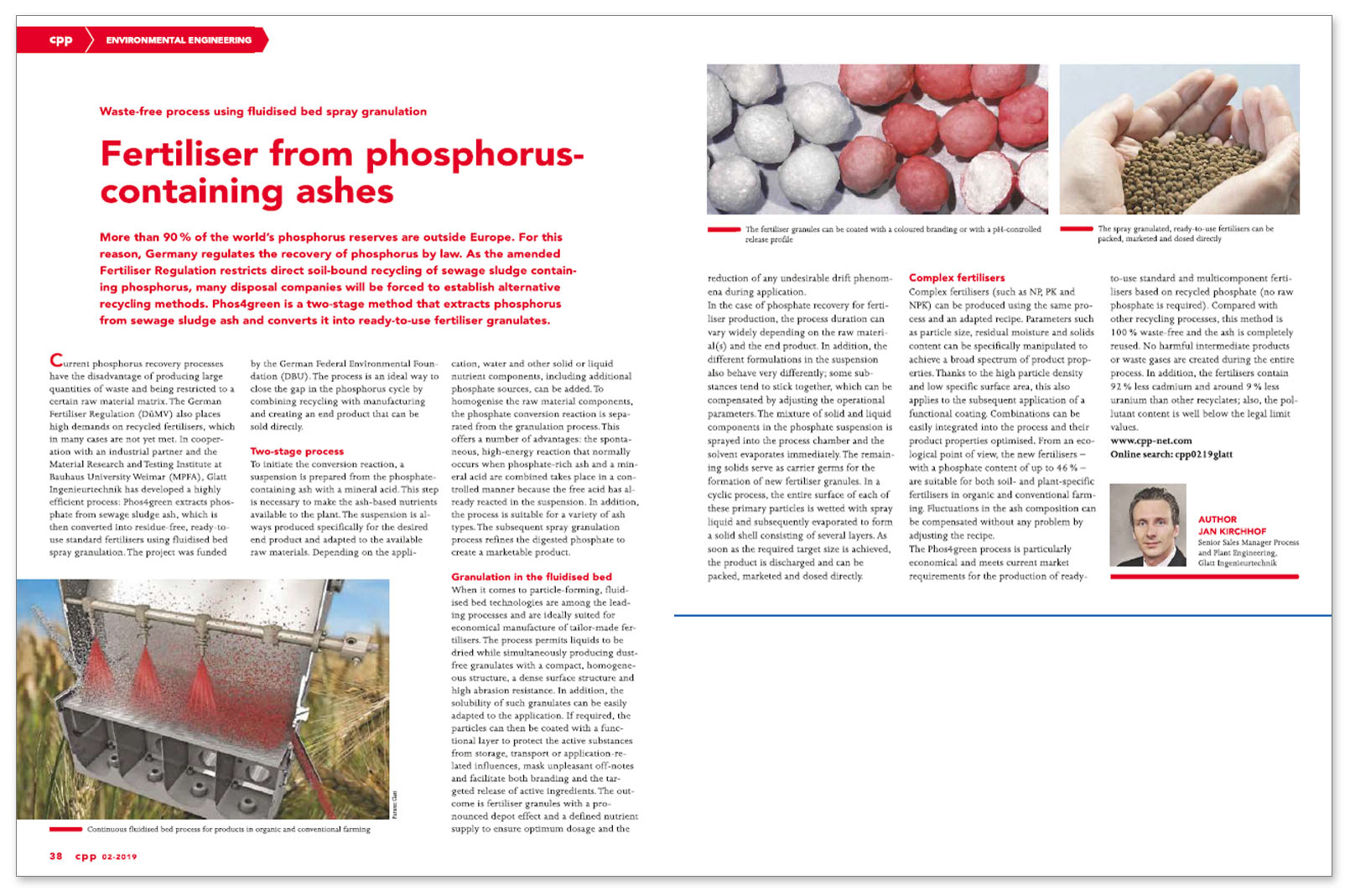

Copyright: Konradin-Verlag Robert Kohlhammer GmbHNew waste-free process produces fertilizer from phosphorus-containing ashes

With "PHOS4green" Glatt presents a new two-stage method that extracts phosphorus from sewage sludge ashes and converts it into ready-to-use fertilizer granulates. In cooperation with an industrial partner and the Material Research and Testing Institute of the Bauhaus University Weimar (MPFA) Glatt has developed a highly efficient process to extract phosphate from sewage sludge ashes, which is then converted into residue-free, ready-to-use standard fertilizers using fluidized bed spray granulation.

Copyright: Palladian Publications

Copyright: Palladian PublicationsPhosphorus recovery: Like a phoenix from the ashes

Jan Kirchhof, Glatt Ingenieurtechnik, Germany, presents a recovery technology that releases phosphate from sewage sludge ashes and converts it into ready-to-use fertilizers

PHOS4green presented at the DWA Conference 2019 in Weimar, Germany

The DWA Technical Committee KEK-3 for "Thermal Sewage Sludge Treatment" deals with the experiences and developments of thermal sewage sludge treatment in plants for mono- and co-incineration and the utilization or disposal of the resulting ashes.

During the meeting of the technical committee on April 03, 2019 in Weimar, Jan Kirchhof, Senior Sales Manager Process & Plant Engineering, Glatt Ingenieurtechnik GmbH, presented PHOS4green as an innovative solution for phosphorus recovery from sewage sludge ash and its residue-free conversion into ready-to-use phosphate standard fertilizers.

Meet the Glatt PHOS4green experts at the POWTECH 2019 Hall 3 / 3-249

Glatt Ingenieurtechnik will be presenting a market-ready process at POWTECH that fulfils the legal obligation of German waste disposal companies to recover phosphorus. In the first step of the two-stage "PHOS4green" process, a suspension is produced from the phosphate-containing ash. The suspension is then spray granulated in the fluidised bed. This results in fertiliser granulates that are available to plants and soil, which can be discharged, filled and delivered directly.

Copyright: Palladian Publications

Copyright: Palladian PublicationsFormulation For Success – Fluid Bed Systemes as Key for the Production of Speciality Fertilizers

From improving durability and flowability through dust reduction to a pronounced depot effect or a targeted nutrient supply via better active ingredient distribution, fluidised bed technology can deliver many benefits. The shape and size of the fertilizer granules can be determined within a defined range. The quantity of fertilizer components delivered to the soil can be adapted optimally, and significantly higher product qualities can be achieved. Solubility and protection against external influences can also be markedly improved.

Glatt Ingenieurtechnik GmbH is one of the 150 most innovative companies in Eastern Germany

In its current issue, the eastern German business magazine WIRTSCHAFT+MARKT presents 150 of the most innovative eastern German companies from seven sectors. These include mechanical engineering, the mobility sector, the IT and digital economy, energy and environmental technology, the healthcare industry, the chemical and plastics industry, and the food and agricultural industry.

Copyright: Johnson-Johnsen Publishing

Copyright: Johnson-Johnsen PublishingFluidised bed processing – Added-value ingredients for better products

The properties of functional ingredients can be fine-tuned using fluidised bed spray granulation, agglomeration, microencapsulation and coating. At Health ingredients Europe, plant manufacturer Glatt Ingenieurtechnik will showcase a new compact spray agglomeration concept for industrial-scale continuous production.

Copyright: Vincentz Network GmbH & Co. KG

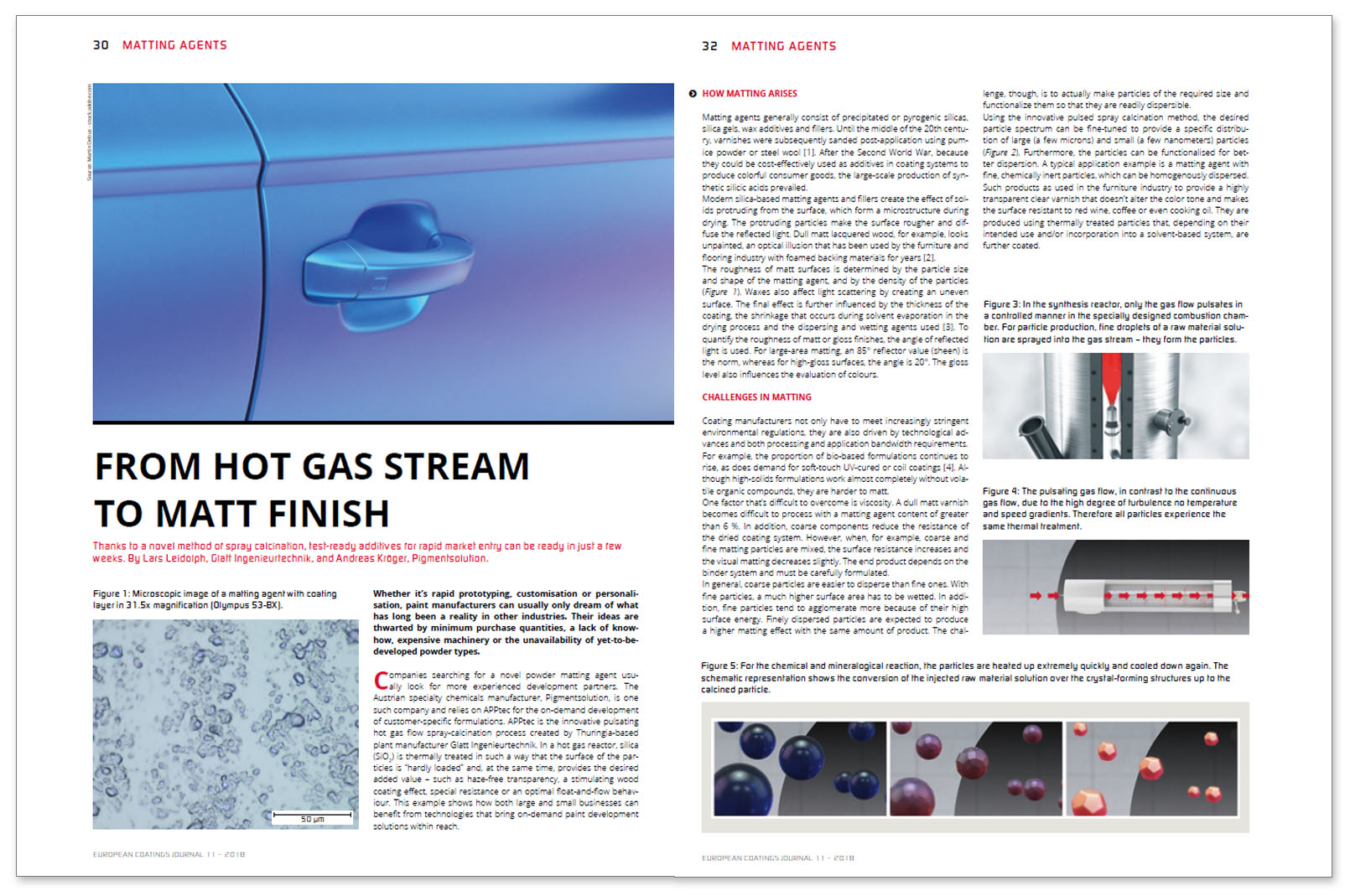

Copyright: Vincentz Network GmbH & Co. KGFrom Hot Gas Stream to Matt Finish by Glatt Powder Synthesis

Whether it’s rapid prototyping, customisation or personalisation, paint manufacturers can usually only dream of what has long been a reality in other industries. Their ideas are thwarted by minimum purchase quantities, a lack of know-how, expensive machinery or the unavailability of yet-to-be-developed powder types. Thanks to a novel method of spray calcination, test-ready additives for rapid market entry can be ready in just a few weeks.

PHOS4green presented at the State Association of the Recycling Industry Saxony e. V. in Leipzig

Phosphorus recovery on the agenda at State Association of the Recycling Industry Saxony on November 13, 2018 in Leipzig. "High-performance fertilizer from sewage sludge ash": this was the title of a presentation by Jan Kirchhof, Senior Sales Manager Process & Plant Engineering, Glatt Ingenieurtechnik GmbH, Weimar, as part of the program on "Phosphorus Recycling - Opportunities and Challenges in Saxony".

Copyright: Palladian Publications

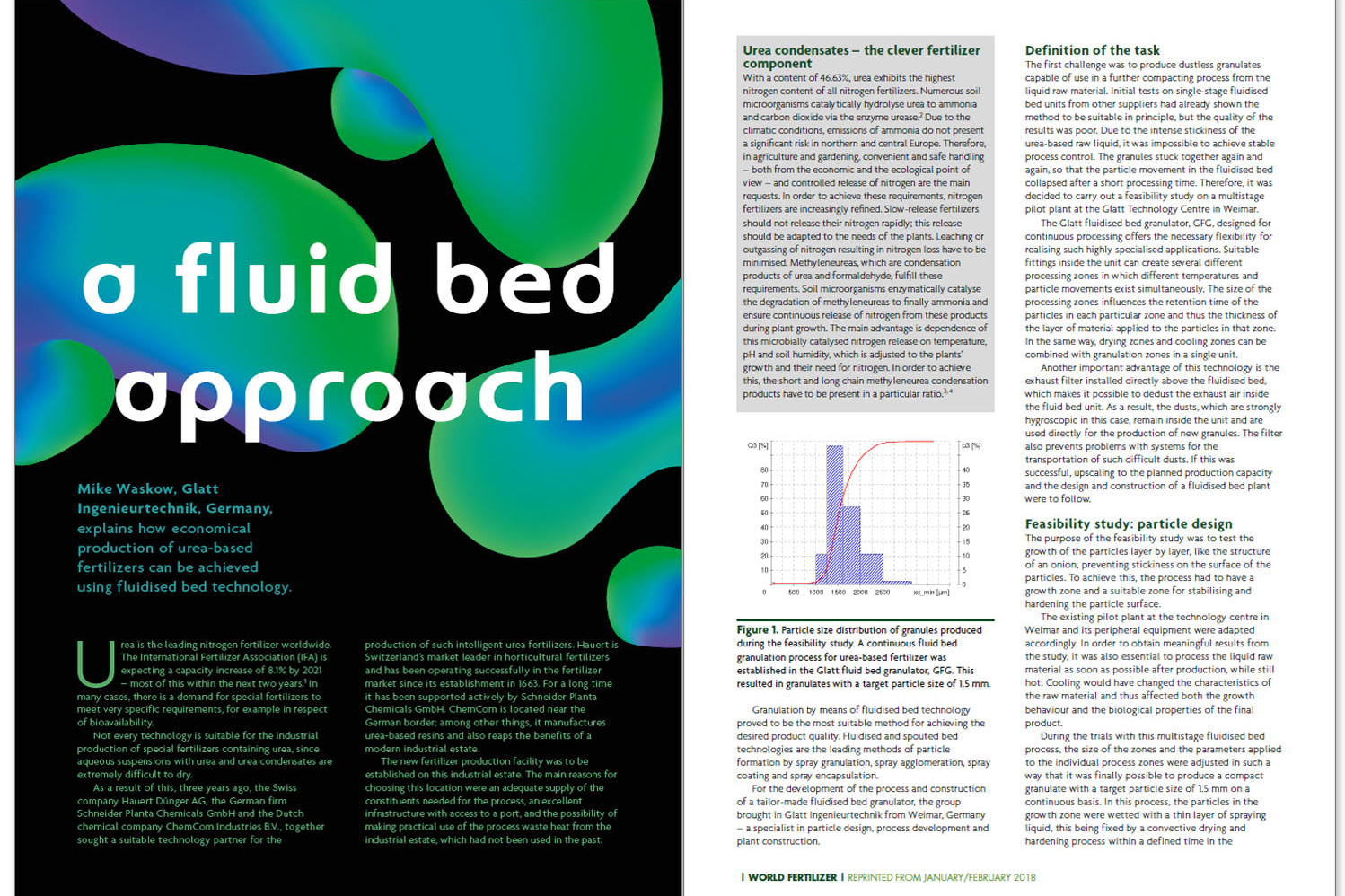

Copyright: Palladian PublicationsA Fluid Bed Approach for Urea-based Fertilizers

Mike Waskow, Process Engineer, Process Technology Food, Feed & Fine Chemicals, Glatt Ingenieurtechnik GmbH, Germany, explains how economical production of urea-based fertilizers can be achieved using fluidised bed technology. (Case study)

Copyright: J.Latka Verlag GmbH

Copyright: J.Latka Verlag GmbHEnhancing product properties with fluid bed and spouted bed technologies

Fluidized bed and spouted bed are among the leading technologies when it comes to improving the physical properties of bulk solids, such as particle size distribution, bulk density, structure and morphology, in order to deliver beneficial application properties like enhanced dispersibility, solubility and flowability. The combination of processes such as drying, granulating and microencapsulating in a single step provides a cost-effective manufacturing solution.

Copyright: Publishing House ERLING Verlag GmbH & Co. KG

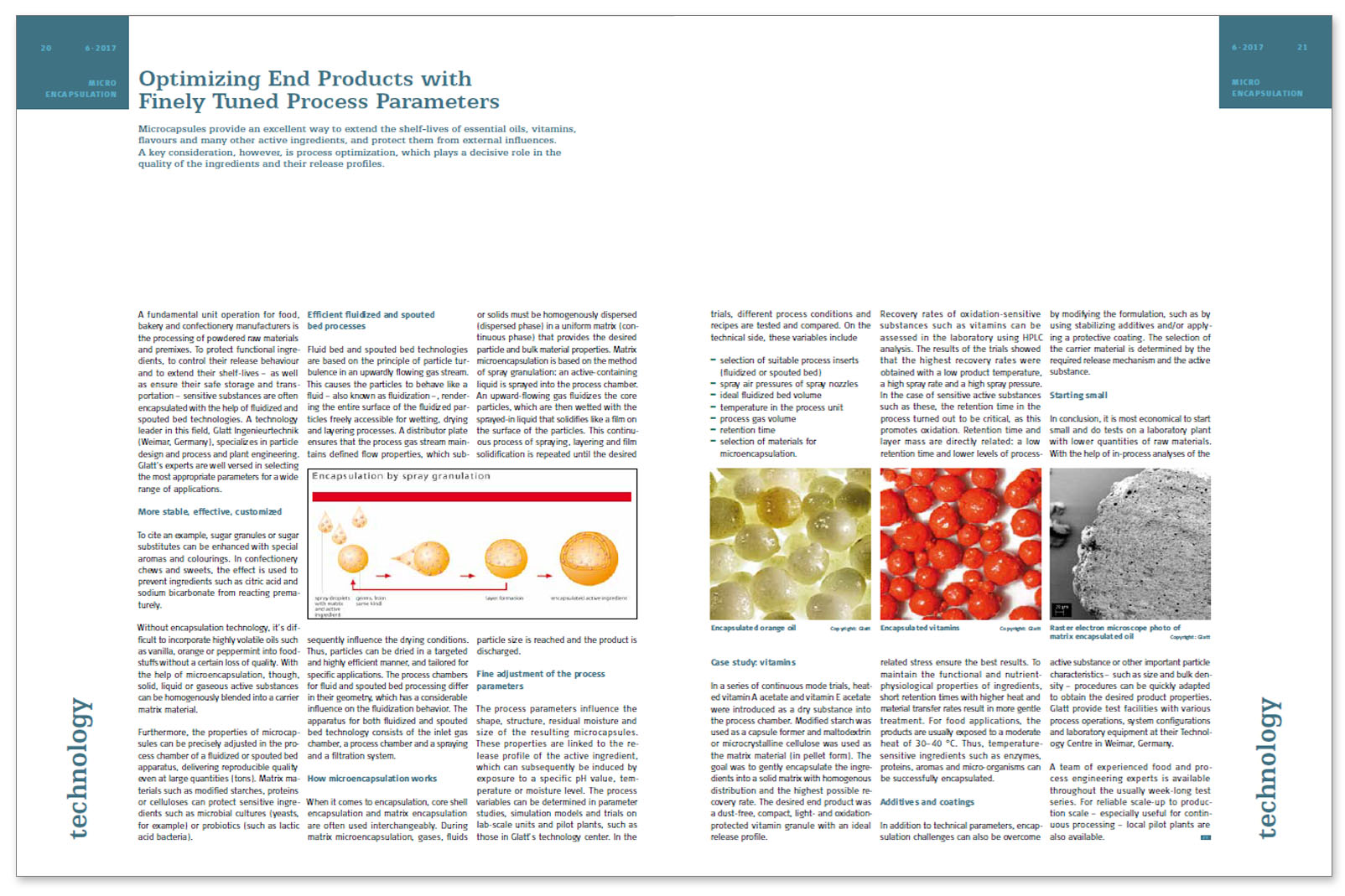

Copyright: Publishing House ERLING Verlag GmbH & Co. KGOptimizing end products with finely tuned process parameters

Microcapsules provide an excellent way to extend the shelf-lives of essential oils, vitamins, flavors and many other active ingredients, and protect them from external influences. A key consideration, however, is process optimization, which plays a decisive role in the quality of the ingredients and their release profiles.

Copyright: Dr. Harnisch Verlagsgesellschaft mbH

Copyright: Dr. Harnisch Verlagsgesellschaft mbHWe support product development from the very beginning

We accompany the product development from the first idea.

INTERVIEW WITH VOLKER BUDZINSKI FROM GLATT INGENIEURTECHNIK

Glatt Ingenieurtechnik from Weimar is a globally active plant engineering company with its own process technology, the fluid bed process. Volker Budzinski is the sales manager responsible for international project development in the Process Technology Food, Feed & Fine Chemicals division. In an interview with the editors of Food Technologie, he answered some questions about fluid bed technology. (German article)

Copyright: Hoskins & Fall Publishing

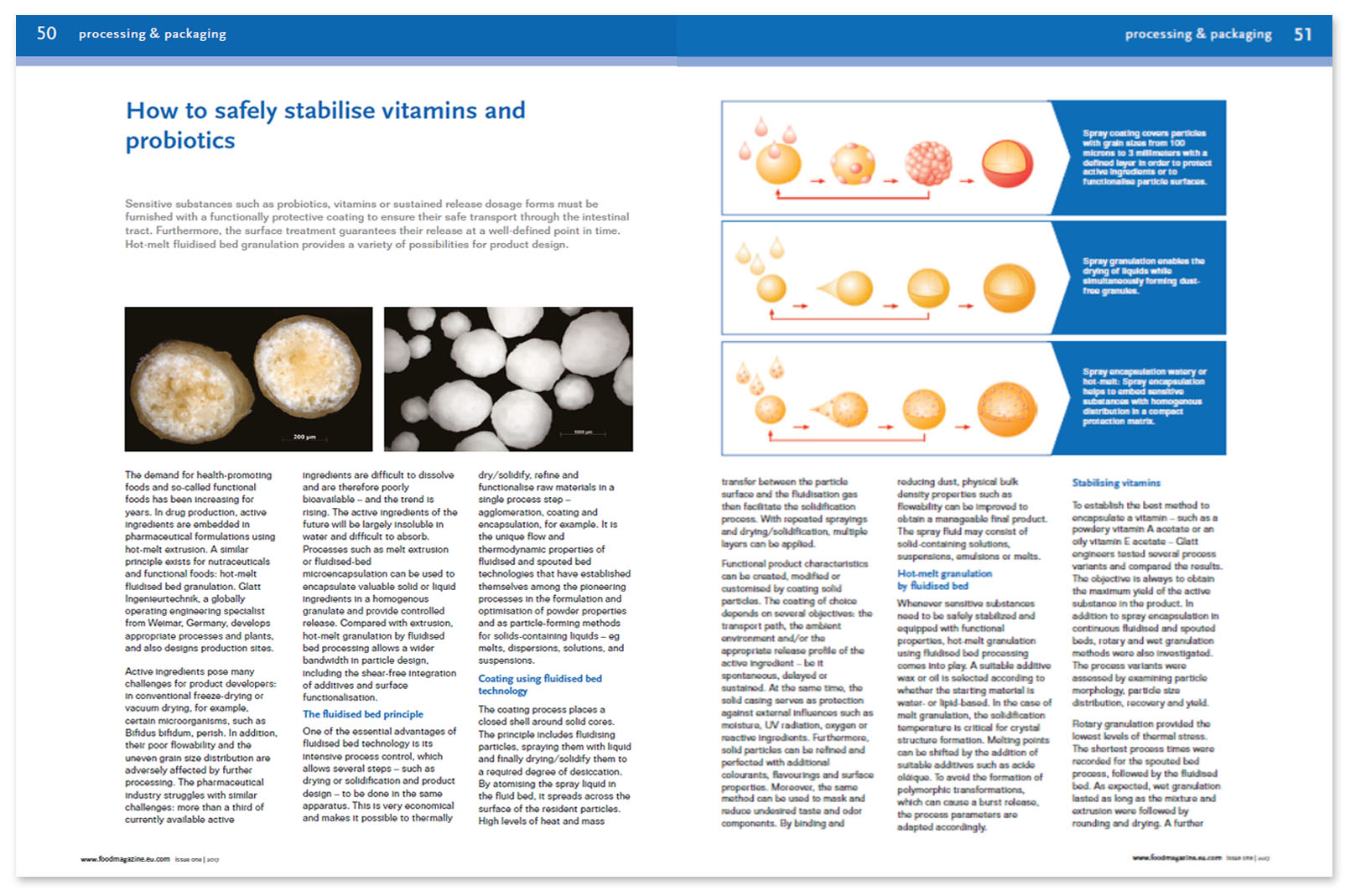

Copyright: Hoskins & Fall PublishingHot-melt applications for the food and beverage industry – How to safely stabilize vitamins and probiotics

Sensitive substances such as probiotics, vitamins or sustained release dosage forms must be furnished with a functionally protective coating to ensure their safe transport through the intestinal tract. Furthermore, the surface treatment guarantees their release at a well-defined point in time. Hot-melt fluidized bed granulation provides a variety of possibilities for product design.

Copyright: Contineo Media Pte Ltd

Copyright: Contineo Media Pte LtdShaken or Stirred – Agglomeration with fluidized bed technology

Whether it’s infant formula, soups or shakes, instant foods are inseparably linked to many areas of life. If powdery substances are to be dissolved or dispersed in hot or cold liquids, then agglomeration is a vital quality improvement process, with fluidized bed technology providing the widest range of optimization possibilities. For the optimization of instant properties, fluid bed technology is a proven, highly adaptable and established technology. The experimental development of critical parameters is essential and should be tested in laboratory and pilot-scale plants to get flawless instant quality products ready for market.

Copyright: Deutscher Fachverlag GmbH

Copyright: Deutscher Fachverlag GmbHCustomised enzymes for optimal animal feed mixes

Technical processes improve the product properties: Feeds need enzymes that work optimally as well as being temperature-stable and storable. Two methods are particularly suitable for producing easy-to-process granules and pellets from sensitive, liquid enzyme solutions - the fluidised bed and the spouted bed methods. The plant manufacturer Glatt lngenieurtechnik is one of the world's leading experts in this field and offers feed producers technology and plant expertise from a single source.

Copyright: B5 S.r.l.

Copyright: B5 S.r.l.Fluidized bed solutions for optimized ingredient production

With populations aging in virtually every nation across the globe, consumer demand for solutions that can tackle age-related conditions such as sarcopenia and keep people active for longer is growing at an impressive rate. The industrial-scale production of innovative food ingredients requires state-of-the-art technologies. Fluidized bed processes offer manufacturers almost unlimited possibilities in terms of optimized particle design and the functionalization of ingredients.

Copyright: Vogel Business Media GmbH

Copyright: Vogel Business Media GmbHA matter of gas flow management – Microencapsulation of essential oils by spray granulation unsing spouted bed technology

Essential oils are volatile substances that are susceptible to oxidation and light. For protection and easier handling, as well as for better dosing and targeted release properties, these substances are increasingly offered and used by various industries in an encapsulated and often free-flowing form.

Copyright: Konradin-Verlag Robert Kohlhammer GmbH

Copyright: Konradin-Verlag Robert Kohlhammer GmbHDesign and operation of energy-efficient fluid bed systems – Integrated approach saves costs

Designing and operating fluid bed systems with energy efficiency: Systems for agglomeration, spray granulation and coating in the fluid bed are used in nearly all industries with the production and refinement of solid product forms. In addition to the material and application properties of the manufactured products their manufacturing costs can also be significantly influenced already during the design of the fluid bed systems.

Copyright: VOGEL Communications Group GmbH & Co. KG

Copyright: VOGEL Communications Group GmbH & Co. KGFull Flexibility with Spouted-Bed – Glatt’s ProCell continuous spouted-bed equipment makes high-quality granulates and pellets

At the end of 2009, one of the world's largest spouted bed systems for granulation started at the Dresden-based contract manufacturer IPC. A ProCell 250 from Glatt Ingenieurtechnik GmbH enables a so far unreached flexibility for agglomeration and spray granulation processes. Liquid and/or solid raw materials can be processed to granulates and pellets or existing particles can be coated. Batch or continuous operation is possible.