Production Plants at the Glatt Technology Center Weimar

Production scale for spray pyrolysis, calcination, drying, granulation, microencapsulation, coating, and …

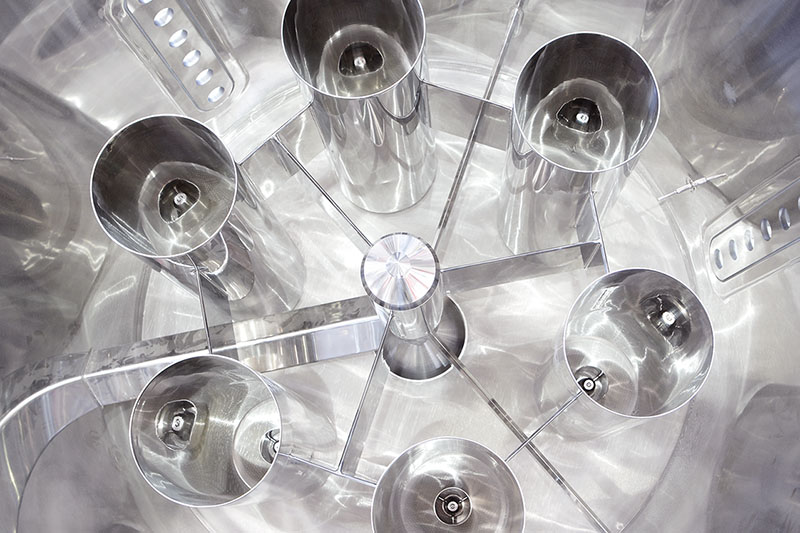

Wurster tubes of a Glatt fluid bed coater

Our modular plant concept for scale-up tests, product sample production or contract manufacturing

For initial production campaigns as well as for longer-term contract manufacturing, modern, modular, large-scale plants are available to you. Here, processes for Glatt powder synthesis in pulsating gas flow as well as all fluid bed batch processes and continuous spray granulation can be carried out.

In many areas, such as the pharmaceutical and biotech sectors, the trend for some years now has been towards patient-specific application forms and thus towards smaller, more flexible production units. Batch processes are the standard here. This trend is also spreading to the food industry. Diversity, specific customer requirements and, in addition, ever shorter product life cycles make investment in large-volume production plants riskier, and the trend toward versatilized technologies or outsourcing is therefore becoming stronger for many areas.

Therefore, the focus of our modular plant concept is on batch-wise fluid bed processes such as coating and spray agglomeration. Our plants are designed to be hygienic and easy to clean for multiple product changes. Therefore, the batch fluid bed is a much used plant concept in the outsourcing business, especially for products that have to be produced in smaller quantities with high quality. Homogeneity in the processing of active ingredients or targeted release profiles through an appropriate coating are easily and reproducibly feasible in the batch, and furthermore traceable. Complex products with expensive ingredients can thus be refined in defined batches with manageable risk. Batch processes allow precisely defined process times and seamless tracking & tracing. In addition, fluctuations in capacity utilization can be easily compensated for by extending the shift operation. Our systems are approved for both aqueous systems and organic solvents. Ready for your specific application.

Continuous processes are also available if required. These energy-efficient long-running systems enable maximum process reliability with minimum operating effort in 24/7 operation.

Glatt fluid bed system/spray coating system GVW 32 / GPCG 200

At our Technology Center in Weimar, Germany, we operate a fluid bed system that is unique worldwide. The plant also processes solvent-based products using nitrogen as the process gas or in a vacuum. Our multi-optional plant for process development, process optimization, scale-up and contract manufacturing with continuous and batch fluid bed and spouted bed processes: a multi-talent for a wide range of applications. The special hygienic conditions for food also enable the production of Kosher and Halal products.

Fluid bed production plant with vacuum operation and solvent recovery at Glatt’s Technology Center in Weimar, Germany

Processes:

» batch: drying, agglomeration, film coating/hot melt coating

» continuous: spray granulation

Working volume: 150 – 640 l

Process inserts: ProCell® 50, WSG 200, 32“-Wurster

- process chamber with conical expansion zone and bottom discharge

- inserts for fluid bed processes:

» top-spray: 3 x 3-head nozzle/ 1 x 6-head nozzle

» bottom-spray: 32” Wurster / 3 nozzles

» ProCell 50 – insert for spouted bed processes / 3 nozzles - process gas flow:

» N2 – loop with 2 condensers

» vacuum – loop operation

» fresh air/exhaust air - volume flow: max. 4.000 m³/h

- inlet air temperature: max. 120°C

- product temperature: max. 80°C

- inlet air conditioning incl. humidification

- indoor air conditioning

- Kosher/Halal

- explosion protection concept: nitrogen inerting and vacuum operation

- environmental protection: solvent recovery by condensation

Glatt fluid bed granulator GPCG 300

The fluid bed granulator and coater for innovative solvent-based processes operates in batch mode and is specially designed for small and medium campaign sizes with frequent cleaning cycles. Special explosion protection measures, a 12 bar pressure shock resistant design and a scrubber for separating the solvents guarantee a high level of safety for employees and the environment. Normal air can be used as process gas for processing products containing solvents. Production capacity ranges up to the three-digit ton range.

Batch processes: drying, agglomeration, film coating/hot melt coating.

Working volume: 300 – 900 l

Process inserts: WSG 300, 32“-Wurster

- process chamber with conical expansion zone and discharge via discharge cone and mobile product container

- inserts for fluid bed processes:

» top-spray: 3 x 3-head nozzle

» tottom-spray: 46” Wurster (6 nozzles) - process gas flow: fresh air/exhaust air

- explosion protection concept: 12 bar pressure shock resistant

- volume flow: max. 8.000 m³/h

- inlet air temperature: max. 140°C

- product temperature: max. 110°C

- inlet air conditioning incl. humidification

- indoor air conditioning

- nvironmental protection: scrubber to remove solvents from the exhaust gas stream

Fluid bed production plant with vacuum operation and solvent recovery at Glatt’s Technology Center in Weimar, Germany

Glatt ProAPP® 300 synthesis reactor

A Glatt ProAPP® synthesis reactor with a reactor diameter of 300 mm is available for the production, modification or coating of customized powder particles in the nano and micrometer range using Glatt powder synthesis in a pulsating gas stream. Very high-quality powder materials in particular are often only required in small quantities. For such special materials, a reactor of this size already represents the production benchmark.

Our Glatt ProAPP® 300 synthesis reactor allows different process options such as particle formation, drying, calcination and core-shell coatings as well as their combination in a single process step.

Unlike our laboratory-scale plants, the oldest pulsation reactor at the Weimar site is not heated electrically, but by a pulsating gas burner. This allows process gas temperatures between 400°C and 900°C.

The gas-fired plant has different systems for product separation, so that both hot and cold separation can be realized.

- process temperatures between 400°C and 900°C

- raw material feed rate up to 100 kg/h

- gas heated system

- hot separation via cyclone as well as two different filter systems for cold separation

Glatt ProAPP® 300 synthesis reactor at the Glatt Technology Center in Weimar, Germany

Further information on this topic can also be found in the following publications:

March 2022: Glatt expands technology center with new laboratory plant for powder synthesis

September 2021: New fluid bed options for solvent-based processes and products

Published article: ‘A matter of gas flow management – Microencapsulation of essential oils by spray granulation unsing spouted bed technology’ PDF, English

Published article: ‘Hot-melt applications for the food and beverage industry – How to safely stabilize vitamins and probiotics’ PDF, English

Published article: ‘Optimizing end products with finely tuned process parameters’ PDF, English