Direct Pelletizing

Spherical, good dosable pellets directly from powder.

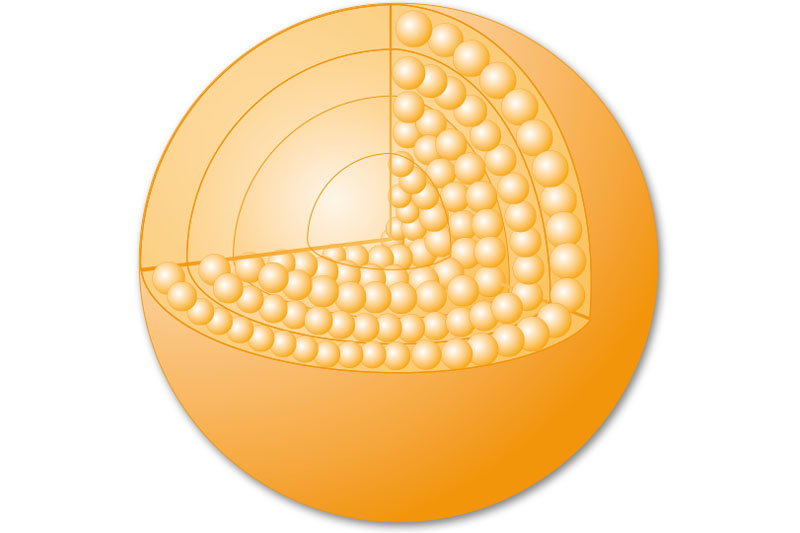

Homogeneously distributed components.

Ideal shape for uniform coating.

Dust-free, dense and spherical pellets directly fast and very effective in the fluidized bed rotor

Direct pelletizing in the fluidized bed rotor is a fast and effective process. Dust-free pellets are produced directly from powder with a binder or solvent. A feed of starting cores is not necessary, so that a high content of active ingredients is possible. The compact, round pellets are ideal for coating processes. They have a high density and are optimally suited for automatic dosing.

Applications can be found, for example, in agricultural chemistry in the field of fertilizers. The rolled-up formulation of active and auxiliary substances can be excellently coated. The direct pelletizing process for enzyme products is also used in numerous applications, for example in the food and feed industry or in detergents. For the formulation of dust-free enzyme pellets, spray-dried enzyme powders or – much more efficiently – liquid enzymes can be incorporated into an excipient matrix.

The smaller surface area of large granule sizes also reduces the amount of coating liquid required. The high bulk density of the granules saves resources in packaging, transport and storage.

For direct pelletizing, Glatt offers batch fluid bed systems with rotor insert for different batch sizes. As a further development of rotor technology, CPS technology with an improved geometry offers optimum solutions for the production of micropellets. Feasibility trials can be carried out in our laboratory plants of the type ProCell LabSystem with rotor process insert.

For applications with organic solvents, the plants can be inertized if required.

Product properties of agglomerates from direct pelletizing in the fluidized bed rotor at a glance:

Spheric

Pellets

Dust-free

Particles

Dense

Surface

Compact

Structure

Low

Abrasion

High

Bulk Density

Good

Flow Behavior

Good

Dosing Capability

Good

Dispersibility

Wide

Grain Size Range

Optimal Shape

for Coatings

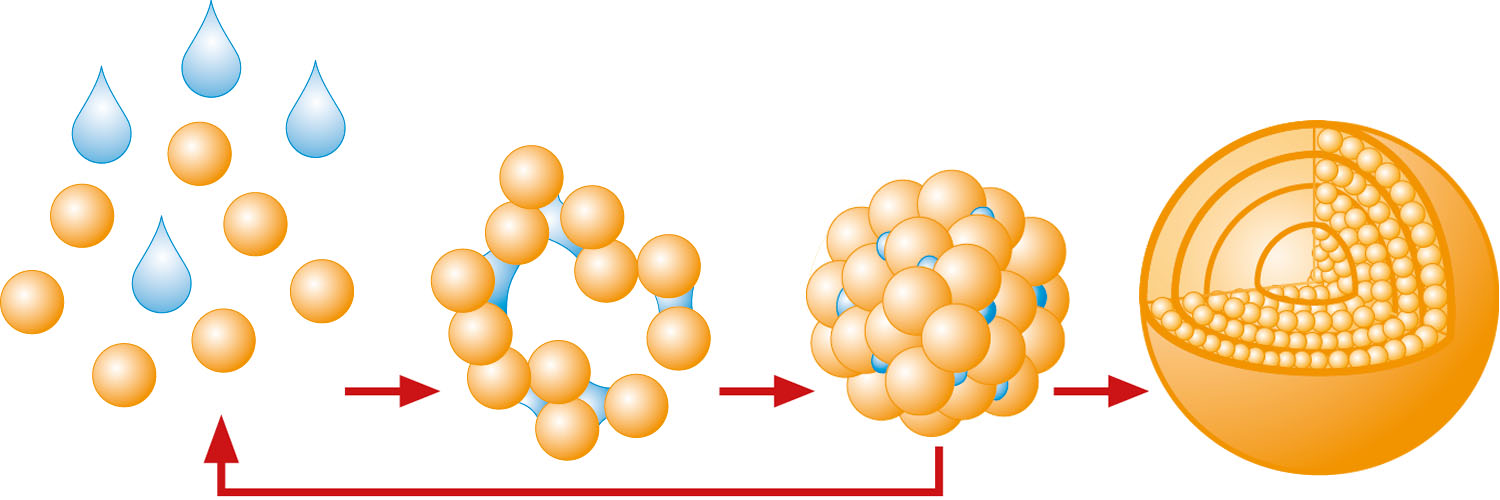

Powder is mixed and moistened. A solvent or binder can be added during this process. The powder bed is set in centrifugal motion.

The tangentially arranged spray nozzle sits directly in the product bed. Due to the adjustable air gap of the rotor, the appropriate air flow can always be selected. The resulting impact and acceleration forces create agglomerates that round out into uniform and dense pellets. The speed of rotation has a direct influence on the density and size of the pellets. The moist pellets are dried by the supplied, heatable process gas in the rotor fluidized bed.

By means of direct pelletizing, pellets can be produced in a wide range of particle sizes with sizes between approx. 200 and 2000 micrometers in diameter.

Another possibility for the direct production of pellets from liquid containing solids is spray granulation. Here, for example, enzyme solutions are dried to form dust-free, highly active enzyme pellets. These, too, can then be perfectly coated.

Product examples

Pigment, direct pelletization

Pigment, direct pelletization, sliced particle

Cellet, direct pelletizing

Zeolite, direct pelletizing

Alumina, spray granulation

The process of direct pelletizing in the rotor fluid bed in detail

Direct pelletizing takes place in three steps: Moistening of the powder mixture, rounding of the moist mass into pellets, drying of the finished product. All process steps take place in the sense of a one-pot process in the fluidized bed rotor.

From the product idea to production

In our Glatt Technology Center, we provide you with access to sophisticated technologies and support in formulation, product and process development, tailored to your individual requirements. The process always starts with tests on a laboratory system. The in-house analytics laboratory enables in-process analyses to adapt particle properties to the respective application. For reliable scale-up, process and operating parameters are determined on pilot plants. Through contract manufacturing at Glatt, your new powders, pellets or granules can be manufactured, filled, packaged and delivered directly in agreed quantities. As a plant manufacturer, Glatt provides all services from project initiation, development and realization through to turnkey production in your own plant.

Further information on fluidized bed and spouted bed processes can also be found in the following publications:

Published article: ‘Optimizing end products with finely tuned process parameters’ PDF, English

September 2021: New fluid bed options for solvent-based processes and products

Published article: ‘Outsourcing – Trust in competent partners’ PDF, English

Brochure A4: Glatt Functionalization of granules and pellets, PDF, English

Brochure A4: Glatt Technology Center Weimar, PDF, English