Analytical Laboratories at the Glatt Technology Center Weimar

Modern analytics for monitoring our processes for your products

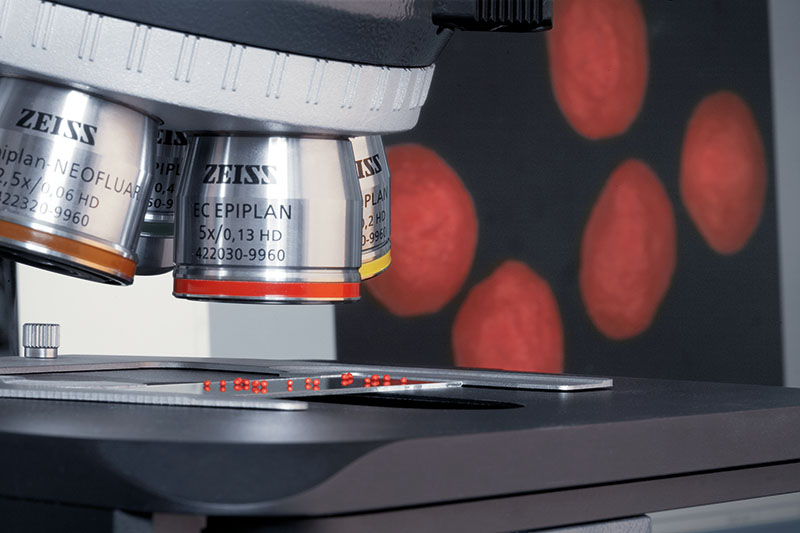

Zeiss microscope in the analytics laboratory, Glatt Technology Center, Weimar, Germany

One of the analytics laboratories in the Glatt Technology Center, Weimar, Germany

One of the analytics laboratories in the Glatt Technology Center, Weimar, Germany

We determine various particles and particle systems with regard to their physical and chemical-mineralogical properties using modern analytical methods.

The right mixture is not only important for your products, but also for our analytics. That’s why we combine modern analytical equipment for focused, granule- and powder-specific analysis with your methods and product-relevant specifications.

For quality assurance in our Glatt Technology Center in Weimar, we have modern equipment for characterizing substances and determining product properties and compositions.

Our analyses are particularly indispensable for process monitoring (IPC) as well as control and also already for emerging plant engineering.

Selection from our analytics portfolio

Our range of services includes the characterization of various particles and particle systems with regard to their physical and chemical-mineralogical properties.

Characterization of product properties (selection)

- particle size and size distribution (photooptical / by laser diffraction and dynamic light scattering or sieve analysis)

- particle shape and form distribution (image analysis)

- moisture content (by halogen, infrared or ceramic radiator alternatively in drying oven)

- bulk density (according to DIN ISO)

- light and electron microscopy

Characterization of material properties (selection)

- pH-value and electrical conductivity and EDX

- liquid rheology, viscosity

- thermal analysis (TGA / DSC)

- chemical analysis / elemental analysis by ICP-OES

- elemental analysis (currently C, H, N, S)

- phase analysis by X-ray diffraction (XRPD)

- specific surface area (BET)

- pore size distribution (e.g. according to BJH) and specific surface area (mostly according to BET) by nitrogen adsorption

- water vapor or solvent sorption or desorption (DVS)

- loss on ignition / ignition residue (muffle furnace)

- volumetric titration (acid-base, redox, water according to Karl-Fischer)

Published article: ‘Food, feed and pet nutrition:

a convergence of industries’ PDF, English

Published article: ‘How to Tame Recalcitrant Ingredients with Technological Processes’ PDF, English

Published article: ‘The gentle processing of highly volatile oils by fluid bed and spouted bed technology’ PDF, English

Published article: ‘New Battery Material by Powder Synthesis’ PDF, English

Published article: ‘Spray (micro)encapsulation of sensitive substances in matrix form – An overview of essential oil and vitamin case studies’ PDF, English