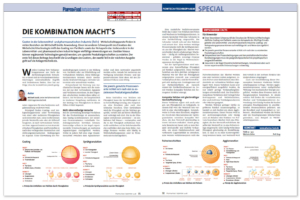

Particle Encapsulation by Coating and Layering

Film coating, lipid coating, hot melt coating, core-shell coating or active substance layering.

Sensory attractiveness.

Protection of particles and environment.

High active substance application.

Release control.

The coating of solid particles can be used for the rapid application of layers with high amounts of active ingredient to a carrier material as well as for coating solid particles with a defined protective layer. In this way, functional product properties can be created, modified or adapted. The choice of coating depends on several objectives: the transport route, the environment and/or the appropriate release profile of the active ingredient – be it spontaneous, delayed or sustained.

A solid particle coating protects against external influences such as moisture, UV radiation, oxygen or reactive ingredients. In addition, solid particles can be refined and perfected with, for example, colorants, flavors, vitamins or minerals. The same processes can also be used to mask and reduce undesirable taste and odor components. The spray liquid can consist of solids-containing solutions, suspensions, emulsions or melts.

Coating and layering processes in the fluid bed or spouted bed as well as in the pulsating gas stream of the Glatt powder synthesis allow a particularly homogeneous distribution of the layer material. Uniform and dense coatings are produced.

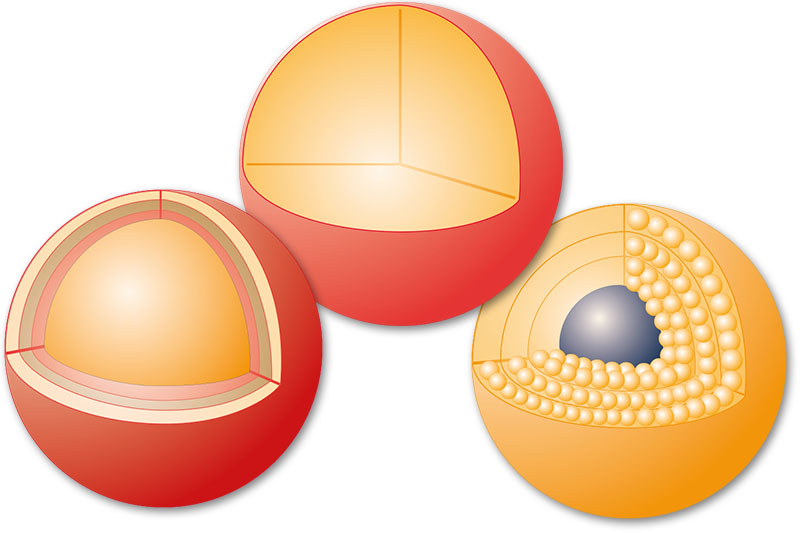

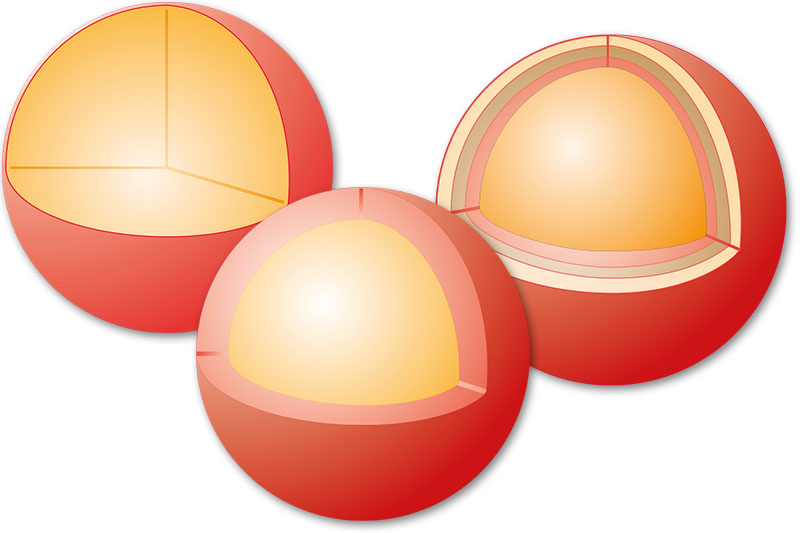

Film, Lipid, Hotmelt Coating

Fluidized bed and spouted bed processes to functionalize particles for sensory appeal, protection and release mechanisms.

Core-Shell Coating

Process in the pulsating gas stream of powder synthesis for protective coatings and new functions for micro- and nanopowders.

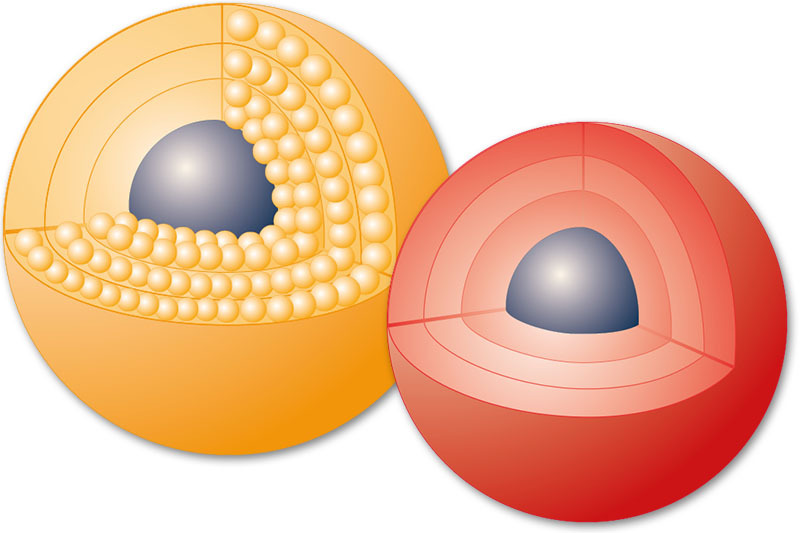

Active Substance Layering

Fluidized bed processes for the deposition of large layer quantities with high active ingredient content on pre-deposited starting cores.

Further information on this topic can also be found in the following publications:

Published article: ‘It’s all in the combination – Coating in the food and pharmaceutical industries, part 1’ PDF, German

Published article: ‘Hot-melt applications for the food and beverage industry – How to safely stabilize vitamins and probiotics’ PDF, English

Published article: ‘Optimizing end products with finely tuned process parameters’ PDF, English

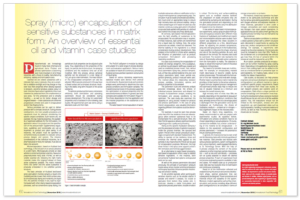

Published article: ‘Spray (micro)encapsulation of sensitive substances in matrix form – An overview of essential oil and vitamin case studies’ PDF, English

Published article: ‘The gentle processing of highly volatile oils by fluid bed and spouted bed technology’ PDF, English