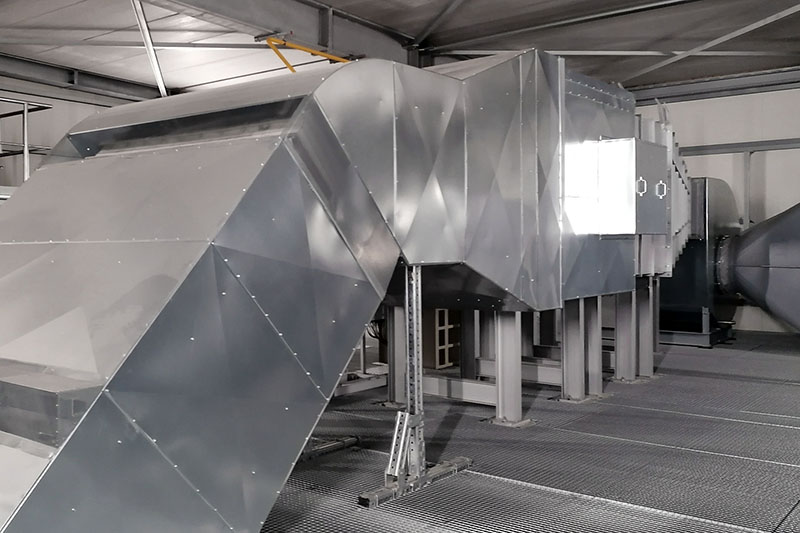

Filter, Glatt fluid bed granulator AGT® 750, continuous spray granulation, phosphate fertilizer, PHOS4green, Germany

Process Gas

Supply air treatment. Nitrogen inerting. Vacuum operation. Exhaust gas cleaning.

The feel-good package for product and environment.

We make a big deal about the quality of air

Your product needs air – for drying, granulating or coating. For a stable process and high product quality, the quality of the air must be reproducible. Quality here means constant temperature, consistent purity and, if necessary, stable humidity. The exhaust air must not pollute the environment – either with product particles, solvents or noise. We offer individual solutions for all these requirements.

With demands for cost savings and responsible use of resources, the effective use of energy is of particular importance.

Approaches to this include:

- precise dimensioning of all apparatus and plant components

- sensible definition of working areas of equipment

- establishment of effective regulation and control systems

- minimization of heat losses partial or complete circulation of process gas volumes

- linking of upstream liquid processes (e.g. evaporation plants) with fluid bed and spouted bed granulators and coaters

- thermal coupling of fluid bed systems with upstream and downstream process stages or also building technology

- integration of various direct or indirect heating systems

- utilization of process waste heat

Comparison of consumption data for different fluid bed system configurations

The determination of the optimal concept in each case must be based on case studies. Here, energy savings with the associated investments as well as the spatial boundary conditions are considered. The system operation itself must also be considered under the aspects of dew point undershoot, winter operation as well as maintenance, corrosion, cleanability.

During the project development phase, the process engineering boundary conditions for the specific application must be determined by investigations on laboratory units and pilot plants. Laboratory analyses can be used in addition to delineate the possible parameter range for process control. Thus, the combination of analytics, trial operation and process simulation enables the development of customer-specific optimized solutions.

Treated supply air. So that your product feels good.

For process gas temperatures up to 120°C (less frequently up to 160°C), we use steam heat exchangers as standard. The air is pre-filtered, heated via a face and bypass system for optimum, fast control accuracy and, if necessary, then finely filtered. In food plants, we use only stainless steel from this filter stage onwards for all parts that come into contact with process air.

Frost protection heating, humidification and dehumidification, higher heating capacity, HEPA filter, housing inside completely made of stainless steel – tailored to your individual requirements, you will receive the optimum supply air treatment unit in each case.

For process gas temperatures above 120°C, we use natural gas burners that operate directly or indirectly. Heat exchangers are often used upstream of the burner to utilize recovered heat.

Process air supply system, contract manufacturing, food supplements, food ingredients, Germany

Inlet air supply system, Glatt AGT® 750 fluid bed granulator, continuous spray granulation, phosphate fertilizer, PHOS4green, Germany

Inlet air piping, Glatt fluid bed granulator GFG 500, continuous spray granulation, chemical product, Russia

Here you can find more photos: Installed plants.

High safety level and efficient solvent recovery in cycle gas operation.

Organic solvents with their specific advantages are still widely used. Whether alcohols, acetone or acetonitrile. Environmental protection requires that emissions from process plants be drastically reduced by using appropriate systems.

If solvents are used, relevant emission protection regulations must be observed. A closed-loop system with condensation not only effectively prevents emissions, but the solvents can also be reused under certain circumstances.

With a closed-loop system, the solvents are condensed out, the process gas is reheated and fed back into the system. The principle can be combined with all plants and processes and offers a number of advantages:

- Recovery of the solvents

by condensation for reuse or disposal - Universal range of application

for all common solvents - High safety level

through N2 inerting of the entire plant

Depending on the solvent, process, product or regulation, scrubbers, adsorption systems, incineration or other processes may be considered. We will be pleased to advise you.

See also: Glatt Safey Concept

High safety level in vacuum operation

In this process, the process plant is evacuated to a working pressure below the LEL (lower explosion limit) by means of a vacuum pump. The vacuum pump extracts the solvent gases and guides them over a condenser on the suction and pressure sides. The absence of inert gas results in excellent heat transfer and thus very effective recovery. (Glatt Safey Concept)

- Recovery of the solvents

by condensation under vacuum - Universal range of application

with all common solvents - High safety level

operation below the LEL - Very effective

due to the absence of inert gases

Exhaust gas cleaning – So that the environment feels good and product loss is reduced

The exhaust air is already filtered in the work tower. For special requirements on the purity of the exhaust air or for safety reasons, we integrate post dedusters with automatic cleaning and / or HEPA filters as police filters. The noise of the fan can be effectively reduced by a silencer and / or shell insulation..

Filter installation, Glatt fluid bed granulator GFG 750, continuous spray agglomeration, instant tea with milk + sugar, USA

Dedusting, contract manufacturing, food supplements, food ingredients, Germany

Filter, Glatt fluid bed coater GFC 2200, continuous spray coating of additives, Scandinavia

Here you can find more photos: Installed plants.

The key role of clever designs for internal and external filters in fluid bed and spouted bed systems

Whether single-chamber or double-chamber principle, shaker or blow-out filter, filter stockings or filter cartridges, whether fabric or metal filter: each system has its specific advantages and is recommended and offered by Glatt in each case for very specific products and processes.

In many applications, the process gas is cleaned by a filter directly above the fluid bed. This process filter plays a crucial role in the process. The filter elements are cleaned in the production process by mechanical shaking or by pulses of compressed air. The dust lands directly in the process again without any losses.

Ingeniously simple. Fabric shaker and blow-out filters – bag filters for easy cleaning even in the plant.

If they didn’t already exist, they would have to be invented: Fabric shaker filters offer a versatile range of applications. Maximum filter surface is combined with simple and effective cleaning by means of a pneumatic shaking cylinder. With the selection of different filter materials, even difficult processes are made possible without any problems – e.g. drying of very moist products. Regeneration is also very simple: remove, wash, install. We therefore uses fabric filter sleeves as standard filters in batch plants. For continuous cleaning, the blow-out filter system with fabric filters is also available.

Continuous plants and multipurpose plants, also for insoluble products, are often equipped with fabric or needle felt bag filters up to five meters long. They represent the most economical type of filter. Glatt bag filter concepts score points in a number of ways, whether with different filter materials, the optimum arrangement of filter bags and cleaning nozzles, or low manpower requirements for plant cleaning. After all, the sum of all filter elements makes up the largest surface area to be cleaned in the plant. Bag filters can be washed in the plant itself or in washing machines. If the filters do not have to be removed for cleaning, a washing chamber next to the filter housing is not necessary. The clean gas chamber is accessible and can be cleaned automatically at the same time. For smaller plants, filter cartridges up to one meter long with filter areas between 3 and 5 square meters are suitable.

Plate filters in space-saving and compact design for innovative room concepts with efficient handling

For several years now, plate filters from Glatt have been able to be removed from the side of fluid bed systems and spouted bed apparatus in a space-saving manner. Their space-saving and compact design can be individually configured and enables innovative space concepts with efficient handling. The filter elements for our fluid bed and spouted bed apparatuses have recently become even smaller, more efficient and more durable. With a smaller number of filter elements – one is only 800 millimeters long and fits on a normally sized desk – the same or even better filter performance can be achieved. The filter plates – with a large filter area per plate – are cleaned outside the system. No space is required above the plant. With a removal to the side, a quick filter change is possible.

Cartridge filter with folded cartridges for significantly more filter area per room unit

Round filter cartridges that can be dismantled upwards are used if the filters are to be removed during washing and removal to the side is not desired. Here, too, the clean gas chamber can be walked on. Once the filter cartridges have been removed, the entire system can be washed automatically.

Plate filters and filter cartridges must be removed from the clean gas side for cleaning. The advantage of external cleaning is that cross-contamination from the filter can be reliably excluded. External cleaning also proves to be more efficient for the complete removal of insoluble, sticky particles or gel-like deposits. The allocation of separate filter sets for individual products or product families provides even greater safety. An integrated room and zone concept regulates the route the filters take to the washing station, how they are dried and stored, and whether airlocks are required for material or people.

Simply ingenious. The patented Glatt SC SuperClean® metal filter

An absolute highlight is the SC SuperClean® filter developed and patented by Glatt. It is mechanically extremely stable and therefore practically wear-free – blow-out pressures of up to 8 bar are possible without any problems. The filter mesh attached to the raw gas side guarantees 100 % surface filtration. The entire cleaning concept enables automatic, validatable cleaning in the closed system. Best conditions for perfect CIP and total containment.

Cyclone and wet scrubber for processes without filters

Some processes can or must do without filters. Then we use wet scrubbers for waste gas cleaning. In most cases, the waste gas is roughly dedusted by cyclones before the wet scrubber. The separated dust is returned to the process and serves as nucleating material for granulation processes.

Various filter concepts can be tested at our Glatt Technology Center in Weimar.

WIP bag filter for multi-chamber design

Filter plate for WIP bag filter in multi-chamber design

Cartridge filter

Single-chamber shaker filter

Twin-chamber shaker filter

Textile blow-back filter

SC-SuperClean® blow-back filter

Filter bonnet

Further information on this topic and related topics can also be found in the following publications:

Published article: ‘A matter of gas flow management – Microencapsulation of essential oils by spray granulation unsing spouted bed technology’ PDF, English

Published article: ‘Cleanly separated – filters in fluid bed systems, an overview’ PDF, German

Published article: ‘Gentle and safe processes – Drying and product design in the vacuum fluid bed’ PDF, German

Published article: ‘Integrated approach saves costs – Design and operation of energy-efficient fluid bed systems’ PDF, English

Published article: ‘How to Tame Recalcitrant Ingredients with Technological Processes’ PDF, English