Glatt PHOS4green

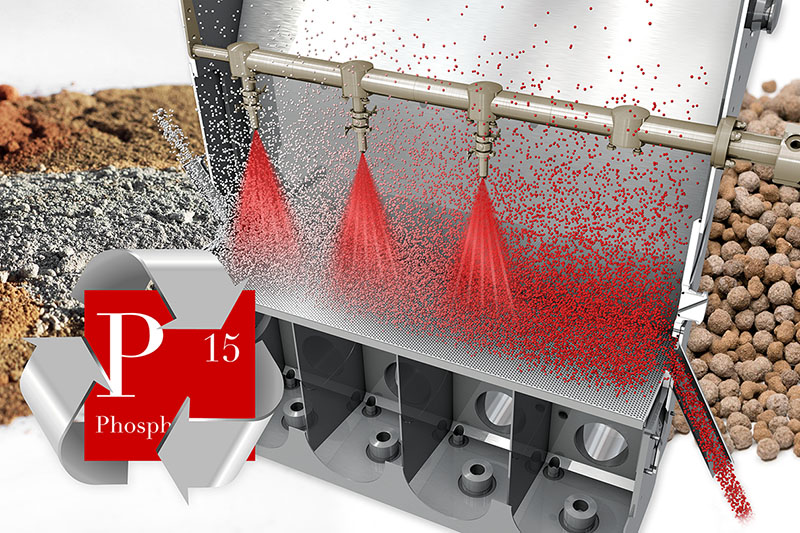

Technology mix for the recovery of phosphorus from ashes with direct conversion into fertilizer granules

With PHOS4green, we have developed an innovative patent-protected technology to recover the essential nutrient phosphorus from sewage sludge ashes and use it for new phosphate or compound fertilizers.

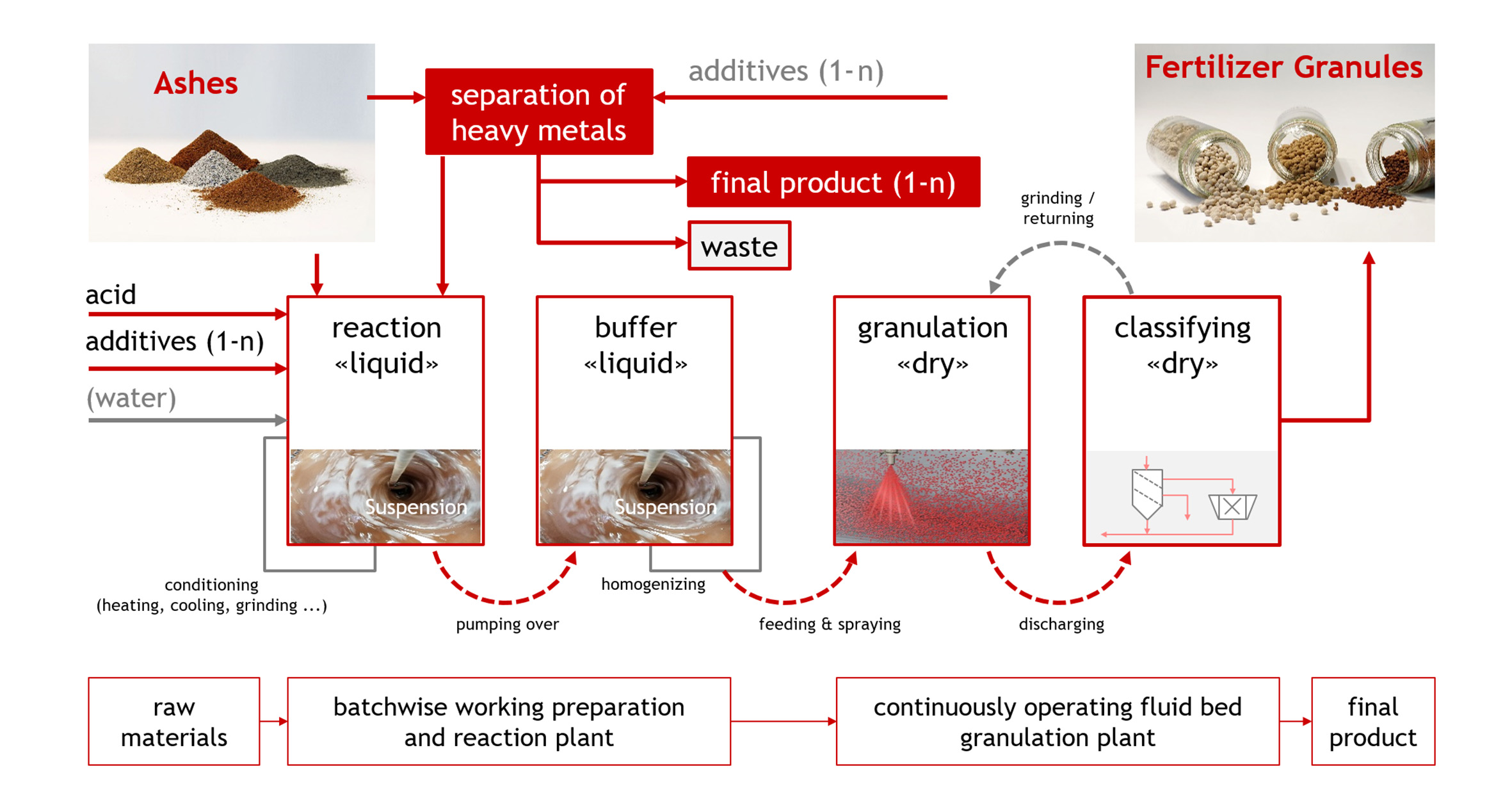

Insoluble phosphates become plant-available due to acidity

Burning sludge to create ashes concentrates the phosphate and removes organic pollutants. These ashes therefore represent a particularly interesting phosphorus source. However, the phosphates present are in an insoluble and thus not plant-available form.

Acids can be used to convert these insoluble phosphates into a form that is available to plants. In a suspension, the poorly soluble phosphate compound is converted in to a plant-available form. The composition of this suspension can be freely defined – even on an industrial scale.

Fast and safe implementation through well-controllable reaction steps

With PHOS4green, no expensive, possibly multi-stage extraction and separation processes are used. The process developed by Glatt is based on process steps that have been in use for decades and have been tested and optimized accordingly.

Quality differences of sewage sludge ashes are compensated by formulation

In the PHOS4green process, the ash is also mixed with the acid. However, the soluble and insoluble fractions are not subsequently separated. Instead, the entire mixture is processed into ready-to-use fertilizer in a subsequent granulation process. This technology is much simpler, significantly less expensive, and does not generate any waste. Fluctuations in the composition of the ashes are easily compensated for by adjusting the recipe. This makes the process extremely flexible, easy to control and ensures consistently high quality fertilizer.

Constant quality of the fertilizers due to defined formulation of the sewage sludge ash suspension

Lyes, basic salts, etc. can be added to the suspension produced with PHOS4green. This neutralizes any free acid that may still be present or achieves the desired pH value.

Further nutrient components can also be added to the suspension, for example nitrogen (N), phosphate (P), potassium (K), magnesium (Mg), sulfur (S) or vital trace elements. This makes it possible to produce standardized mineral fertilizers with the desired plant- and soil-specific nutrient composition.

As a plant manufacturer, we offer fluid bed granulators and coaters for laboratory testing and process development, scale-up and production.

How the two-stage, residue-free PHOS4green process turns sewage sludge ash into ready-to-use fertilizer containing phosphorus.

Further information on this topic can also be found in the following publications:

Published article: ‘Growing the German phosphate industry’ PDF, English

Published article: ‘Improved performance for crop protection products’ PDF, English

Published article: ‘Like a phoenix from the ashes’. A recovery technology that releases phosphate from sewage sludge ashes and converts it into ready-to-use fertilizers. PDF, English

Published article: ‘Fomulation For Success – Fluid Bed Systemes as Key for the Production of Speciality Fertilizers’ PDF, English

Published article: A Fluid Bed Approach – Case study on the economical production of urea-based fertilizers can be achieved using fluidised bed technology, PDF, English