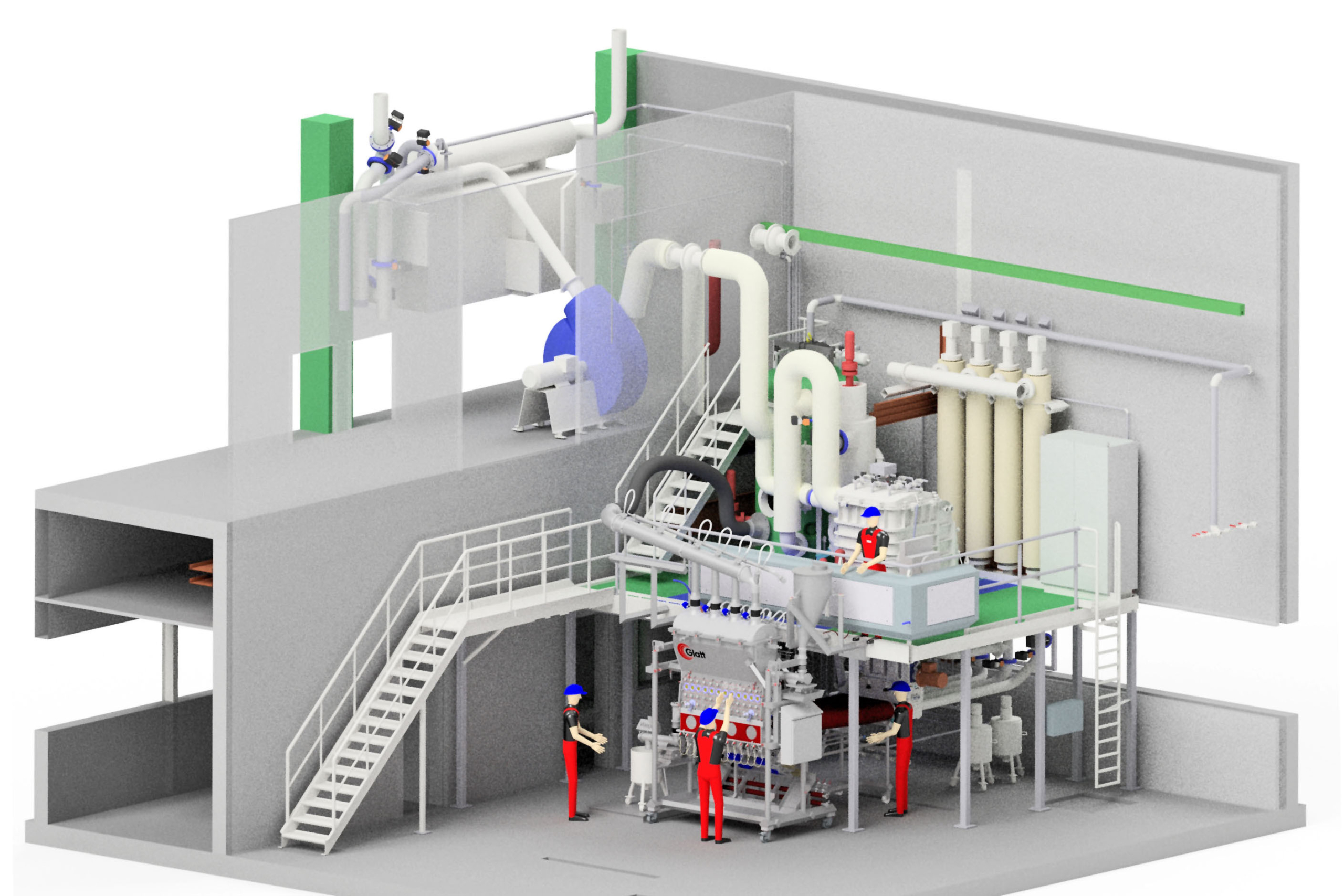

Glatt ProAPP® 300 synthesis reactor

A Glatt ProAPP® synthesis reactor with a reactor diameter of 300 mm is available to you for the process development of customized high-performance powders by means of Glatt powder synthesis in a pulsating gas stream. This pilot/production plant allows different process options such as particle formation, drying, calcination and core-shell coatings as well as their combination in a single process step. The knowledge gained in laboratory tests can be used here directly in pilot tests to design production plants.

Unlike our laboratory-scale plants, the oldest pulsation reactor at the Weimar site is not heated electrically but by a pulsating gas burner. This allows process gas temperatures between 400°C and 900°C.

The gas-fired plant has different systems for product separation, so that both hot and cold separation can be realized.

- process temperatures between 400°C and 900°C

- raw material feed rate up to 100 kg/h

- gas heated system

- hot separation via partial flow hot gas filter, as well as cyclone or two different filter systems for cold separation