Glatt spray system for a Glatt fluid bed coater GFC 2200

Liquids

Processing of liquids of any kind.

With consistently high product quality and maximum process reliability.

Constant product quality! Whether thin solution, thick suspension, waxes, polymers or melt.

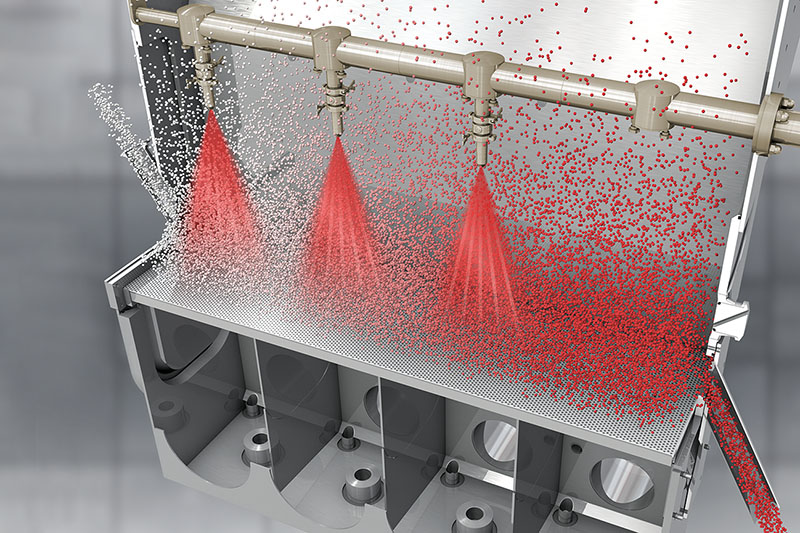

Process reliability and constant product quality are essentially determined by uniform atomization of the liquid raw material. Parameters such as spray pressure, droplet size, spray cone and droplet velocity must be reliably controlled. Nozzle design and distribution in the fluid bed or in the spouted bed are equally important. We combine decades of experience with modern simulation and modeling calculations to achieve the optimum distribution of the liquid in the process chamber.

Uniform distribution of the liquid raw material to all nozzles must be ensured at different spray rates and different viscosities. Whether thin solution, thick suspension, polymers or a melt – for example of lipids, fats or waxes – we offer the right solution. Whether simple peristaltic pumps or ring distributors with flow meters for each nozzle, we have already built (almost) everything, depending on the requirements of the process and the customer’s wishes.

Water or organic solvents

If the liquid does not become stable enough with water or by melting, organic solvents can be the solution. We have worked with many different solvents, even in mixtures and at elevated temperatures. Safety and environmental protection are then, of course, paramount.

Spraying hot liquids of all kinds

It is not unusual for liquid starting materials to have to be heated in order to be sprayed. Whether it’s a supersaturated solution, a melt in its own hydrated water, or molten waxes and polymers, Glatt has extensive experience in hot melt processes as well as in the safe distribution and metering of other hot liquids. This includes options for cleaning fluid lines, distribution fittings and measuring instruments at the end of production.

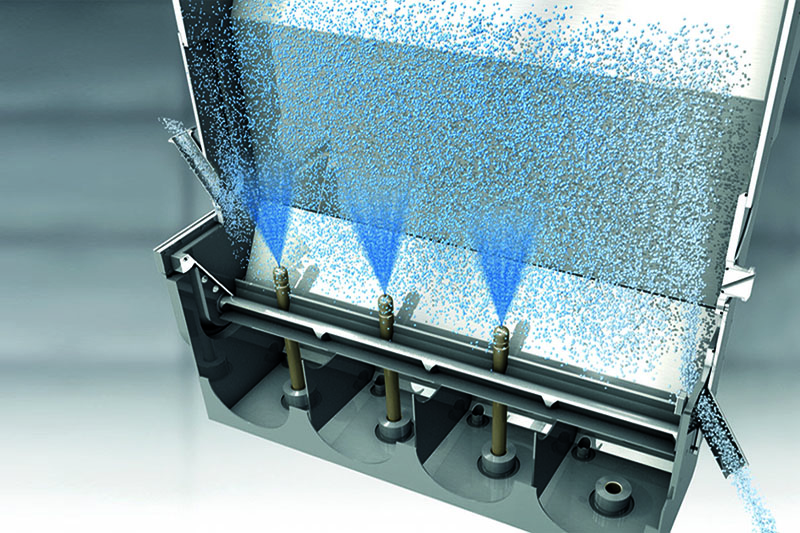

Hygienic, explosion-proof demountable spray nozzles for maximum process reliability

Glatt sets standards in process safety and plant availability with hygienic, explosion-proof demountable spray nozzles. Continuous fluid bed systems and spouted bed systems with multiple spray nozzles continue to run with the same product quality and system safety. Nozzle protection saves plant downtime, increases personal, operational and occupational safety, and reduces potential sources of operator error. In addition, the empty outer tube can be washed at the same time as the washing process.

Top spray process in a continuously operating fluidized bed system

Bottom spray process in a continuously operating fluidized bed system

Hygiene-compliant, explosion-proof demountable spray nozzle

Glatt ProCell® System 250, connection spray system, contract manufacturing, food supplements and ingredients, Germany

Suspension preparation, Glatt fluid bed granulator GFG 850, continuous spray granulation of potash, Germany

Water treatment plant, contract manufacturing, food supplements and ingredients, Germany

Acid tanks for continuous spray granulation from suspension of sewage sludge ash, phosphate fertilizer from phosphorus recyclates, PHOS4green, Germany

Preparation system, Glatt AGT® 750 fluid bed granulator, continuous spray granulation, phosphate fertilizer, PHOS4green, Germany

Spraying system, Glatt fluid bed granulator GFG 850, continuous spray granulation, potash, Germany

Here you can find more photos: Installed plants.

Further information on this topic and related topics can also be found in the following publications:

Published article: ‘Spray agglomerating plant-based milk alternatives for optimised product properties’ PDF, English

Published article: ‘Gentle and safe processes – Drying and product design in the vacuum fluid bed’ PDF, German

Published article: ‘Hot-melt applications for the food and beverage industry – How to safely stabilize vitamins and probiotics’ PDF, English

Published article: ‘Spraying cleanly without a break – Hygienic design of fluid bed and spouted bed systems’ PDF, German

Published article: ‘It’s all in the combination – Coating in the food and pharmaceutical industries, part 2’ PDF, German