Our Planning Services across all Project Phases

From the basic points to the detailed documentation for the implementation of your project.

Rely on our sound technology know-how for individual and sustainable planning of your investment project!

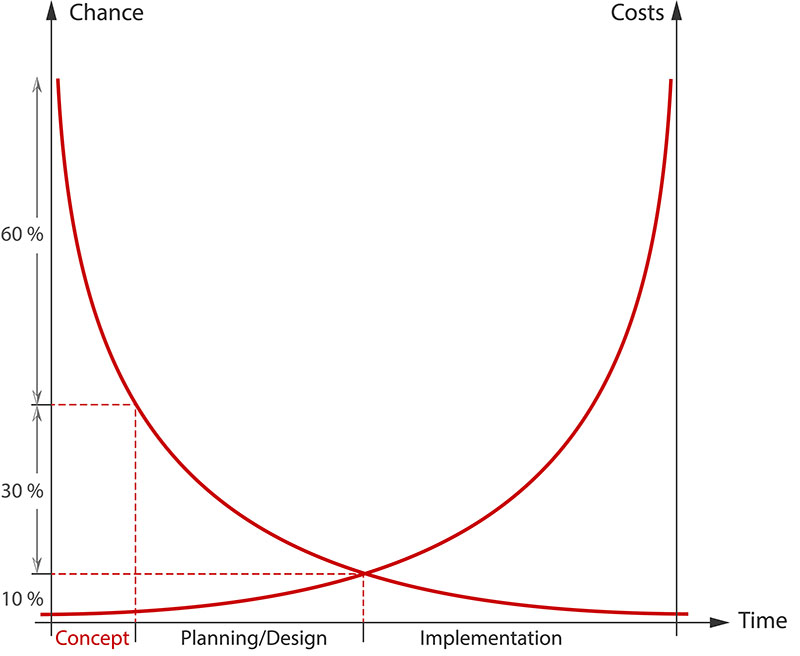

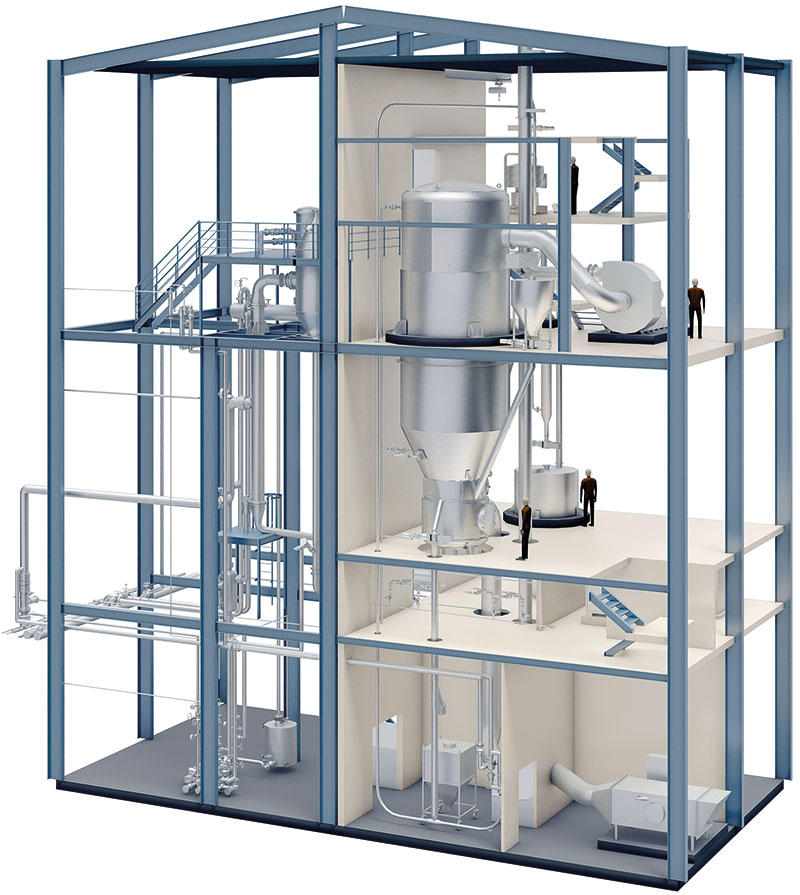

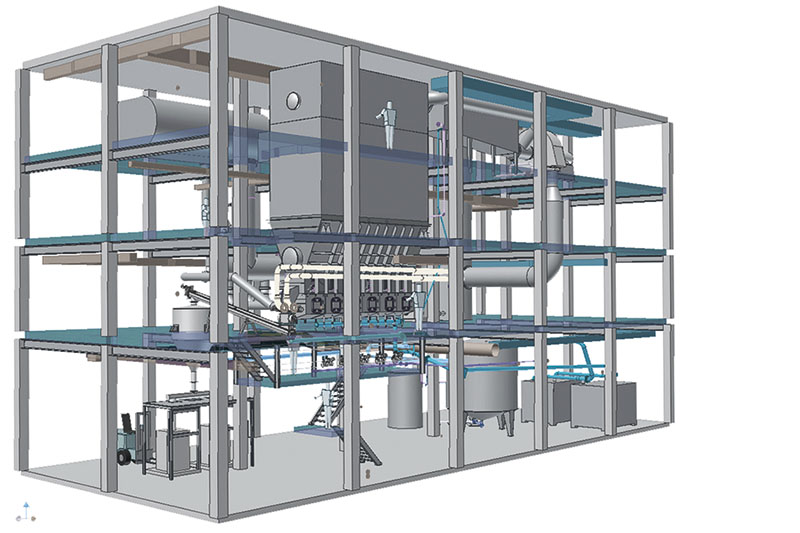

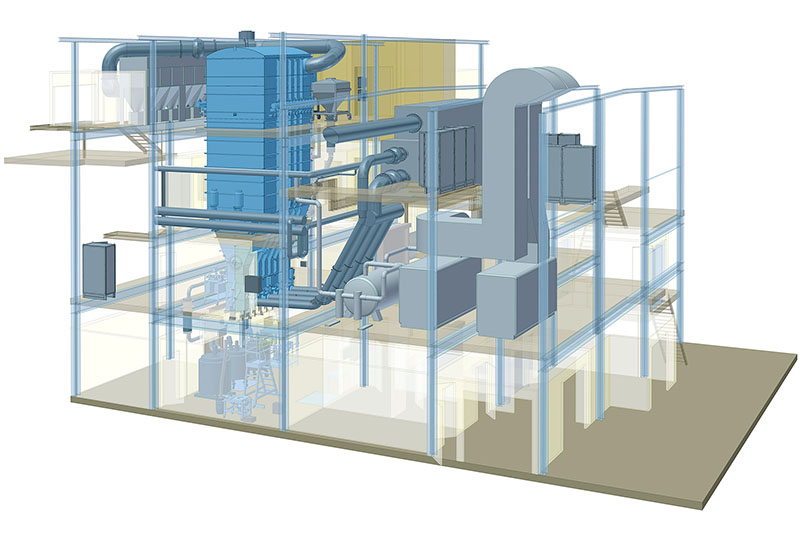

Whatever you want to realize – only early, holistic planning will provide you with the desired result. Whether it’s a conversion or a new construction of your production facility: As a technology-oriented planning partner, we accompany you from your initial idea through all phases of planning – starting with the first concept and ending with detailed execution documents. Our systematic, feasible planning ensures that all potential is exploited in advance of your investment. Tailor-made for your production.

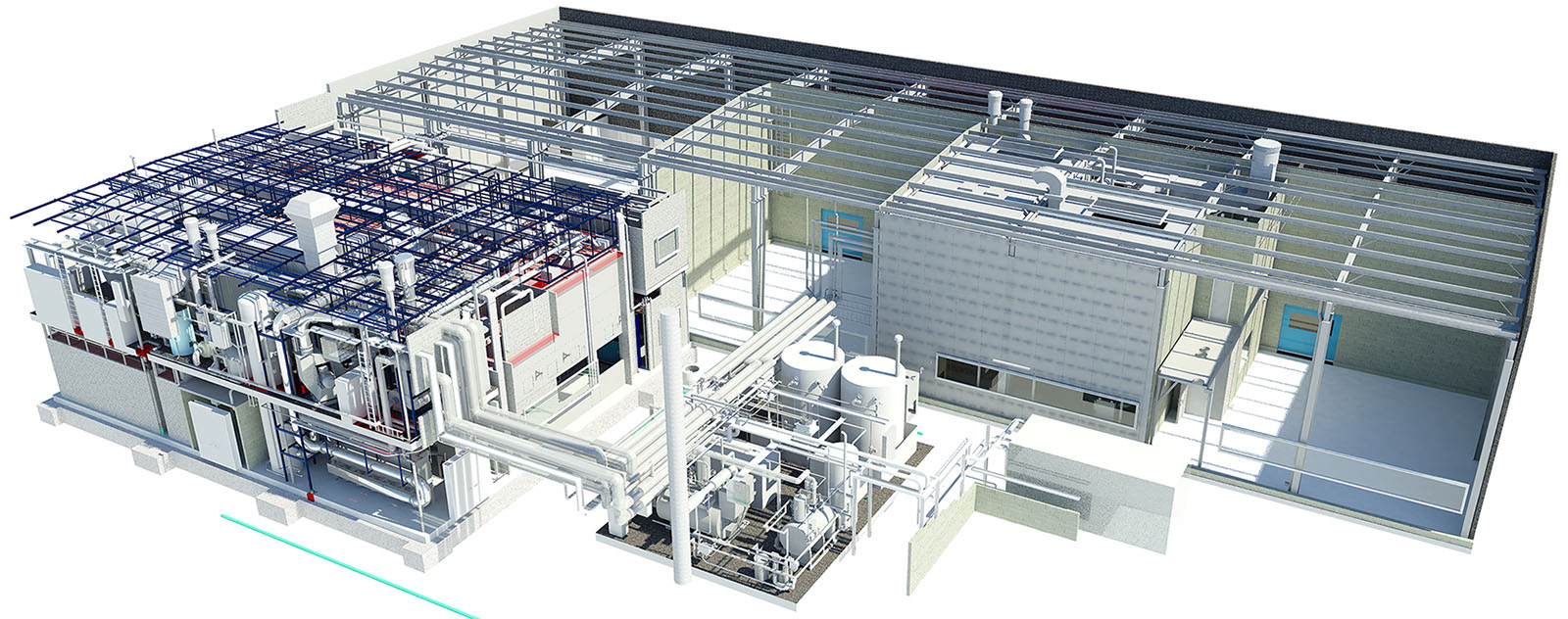

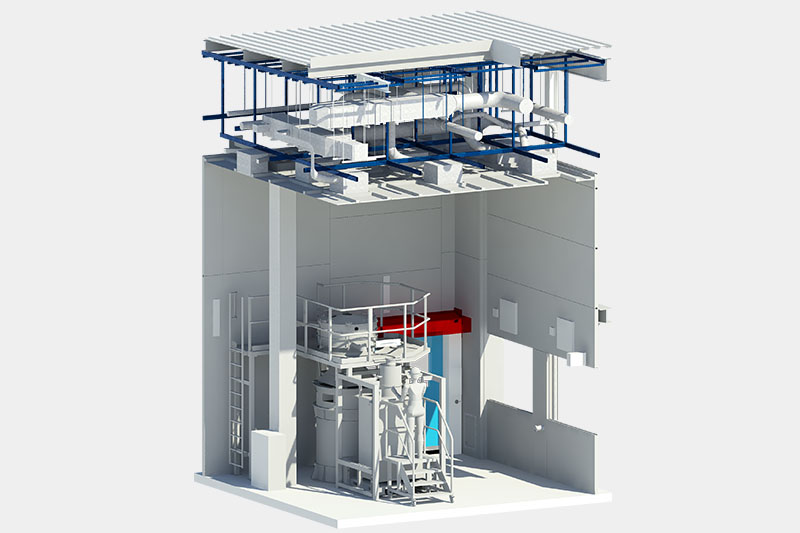

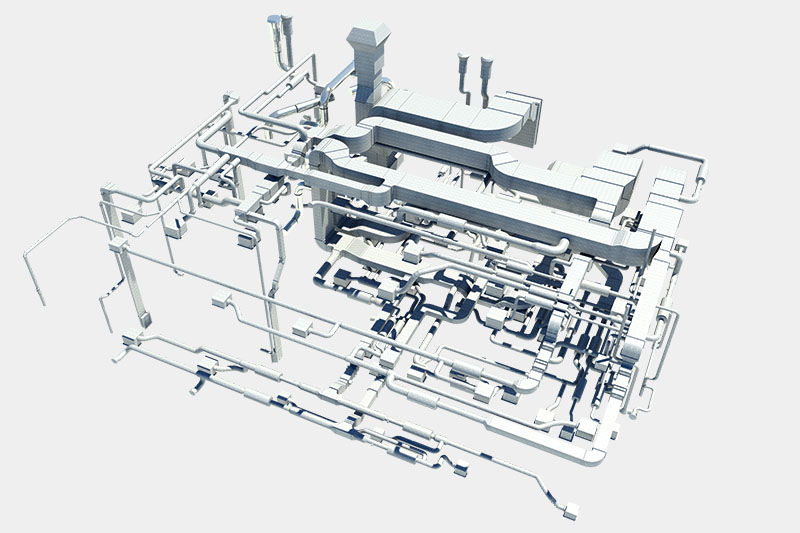

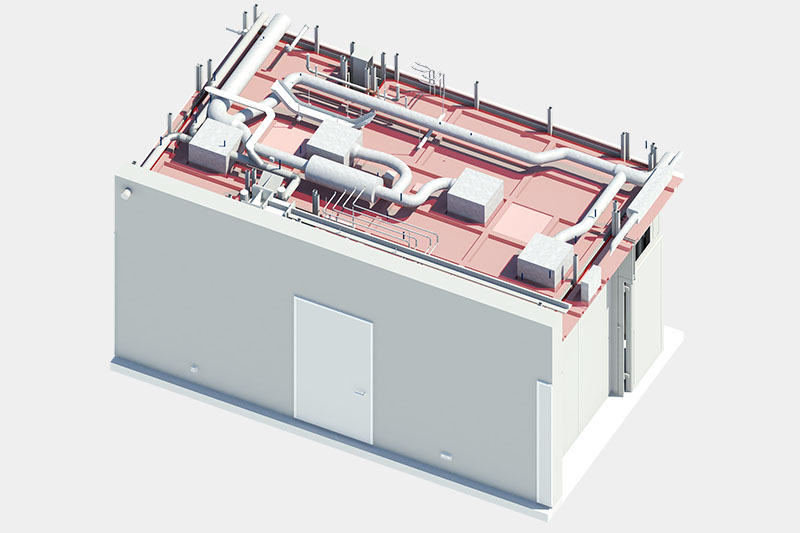

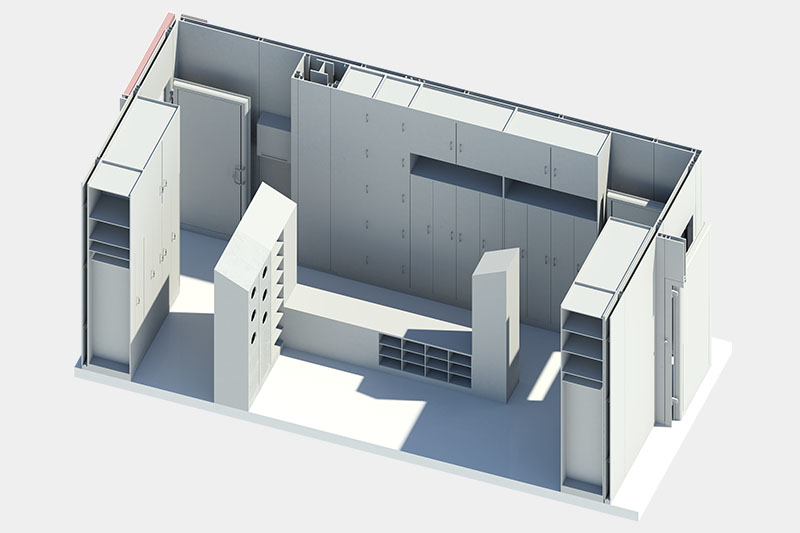

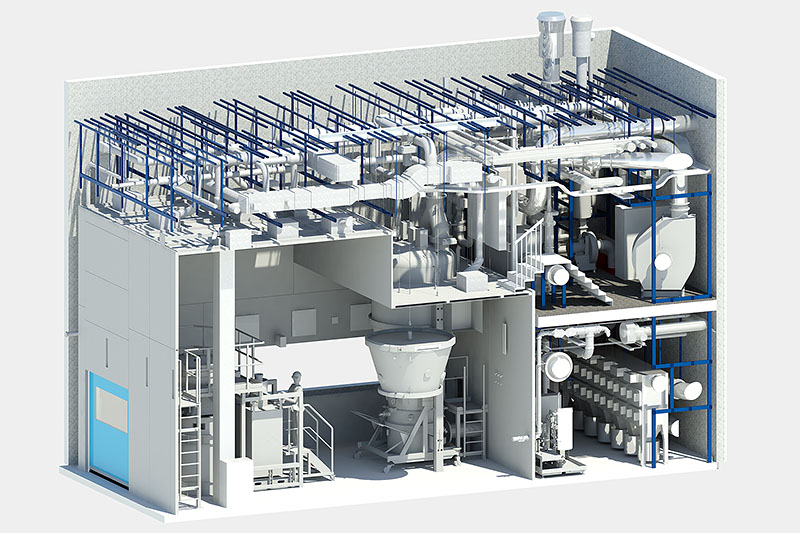

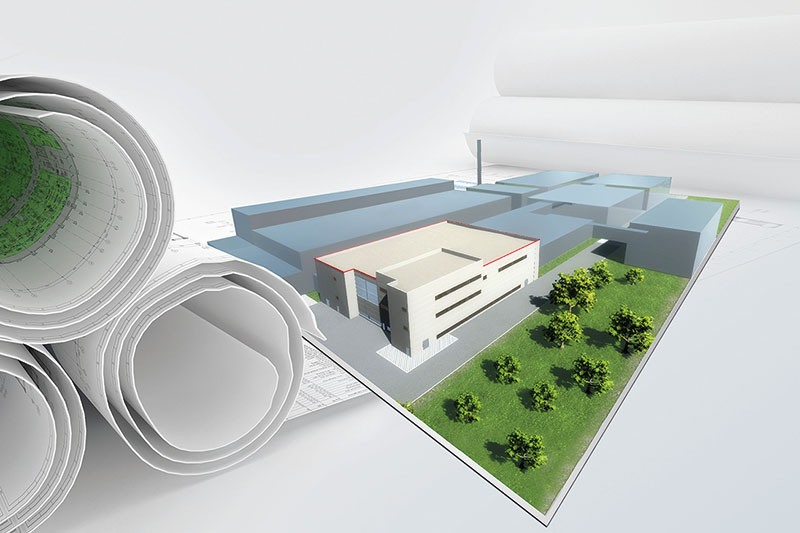

Glatt plant and factory engineering: Our planning services across all project phases. 3D design of a complete production facility

Production area

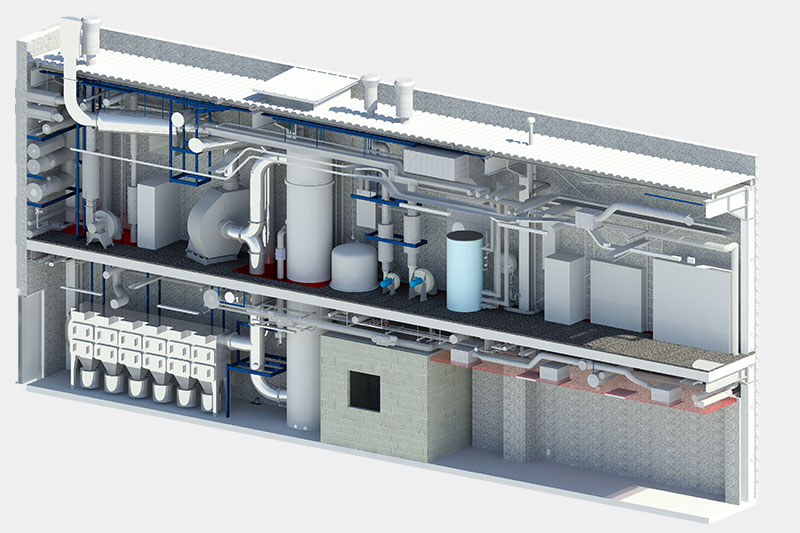

Technical area

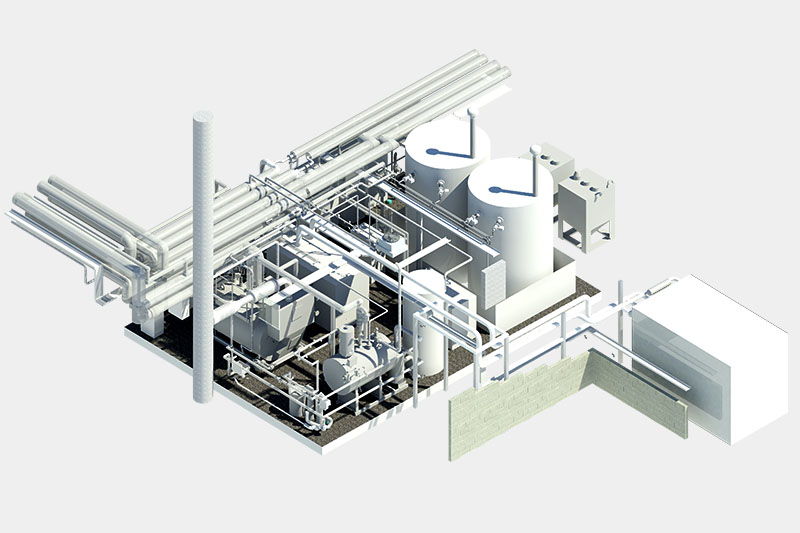

Energy center

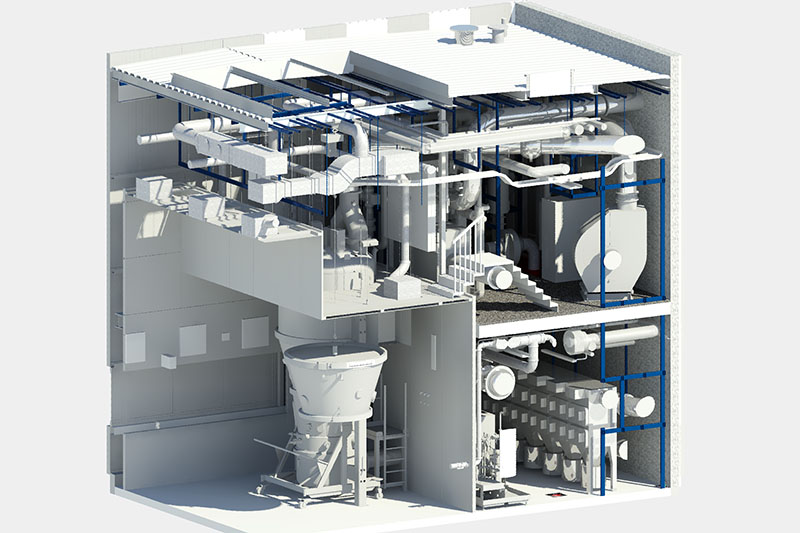

Production room, detail

Duct network ventilation

Intermediate ceiling airlock

Lock furniture

Production room + intermediate ceiling + technical area

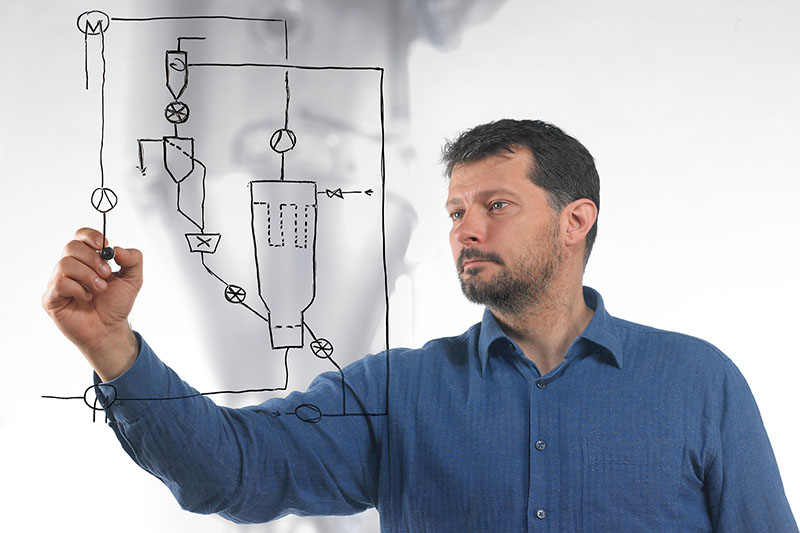

Concepual Design / Pre-Engineering

Important basis and success factor for your investment project

Assessing the initial situation, finding, evaluating and presenting options and alternatives are the tasks in this phase of the project process.

In the concept phase, the fundamental course is set for the implementation of your project according to your specifications. From day one, we bring our comprehensive technological expertise to bear in the planning process. This enables us to completely align the project planning with your resources and specific technology. In a basic evaluation phase of your project idea, our experts draw up an initial technological concept for you. This identifies important aspects for further project implementation and analyzes risks. Based on an initial calculation of the key economic project figures, consisting of budget investment costs (CAPEX), operating costs (OPEX) and a first preliminary schedule, you will receive a solid decision-making basis for the further planning of your project.

As an ideal basis for your investment decision and subsequent project phases, we provide you with a finished concept with a customized layout that integrates all components of the production process. Requirements for explosion and fire protection, heat recovery, energy efficiency, hygienic design and cleanability are taken into account, as is the minimization of emissions to air and wastewater. This concept is optimized for the conditions of the raw materials to be used, your media available at the site and the parameter specifications for the end product.

The pre-engineering documentation is the basis for the preparation of the business plan.

Selected customized services:

- definition of the task

- definition of the raw materials

- definition of the media available at the site

- description of the procedure including process, block flow diagram

- equipment and capacity calculations (main equipment list)

- interface description

- layout concept including layout plan and alternatives

- risk and safety considerations

- utility concept: external/internal media with specification, ventilation and air conditioning layout, electrical planning (layout)

- automation concept

- preliminary building layout

- cost estimation +/- 20

- rough project time schedule

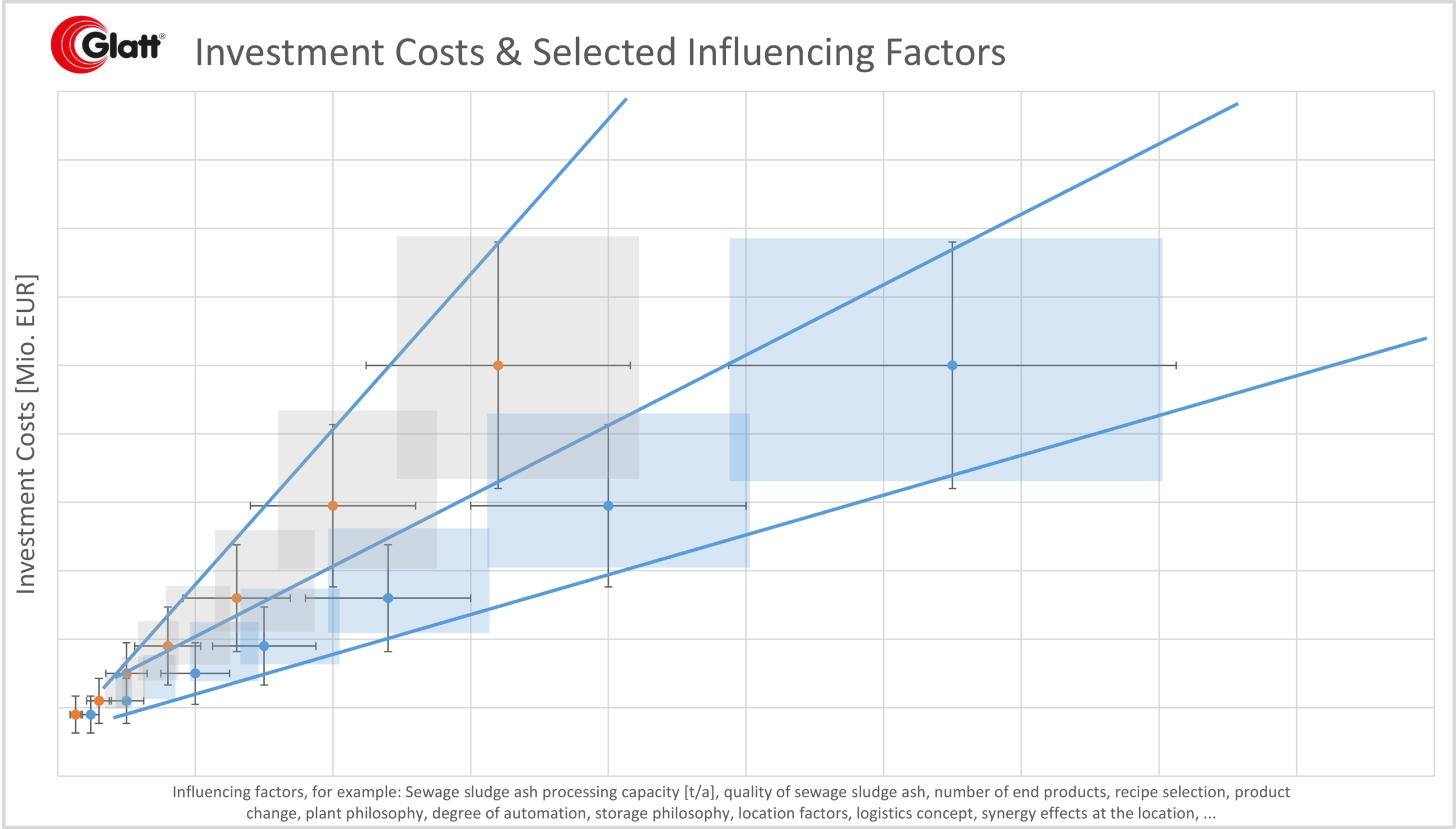

Various factors, such as the capacity to process the sewage sludge ash [t/a], the quality of the sewage sludge ash, the number of end products, the recipe selection, the planned product changes, the plant philosophy, the degree of automation, the storage philosophy, the logistics concept, site factors including potential synergy effects at the site (e.g. use of waste heat from other processes to heat the process air in the fluid bed granulation process, use of existing infrastructure for raw material delivery, transport or end product storage, connection to existing supply systems such as steam, electricity or compressed air), have a considerable influence on the investment costs. We will of course advise you as we develop optimal concept with you.

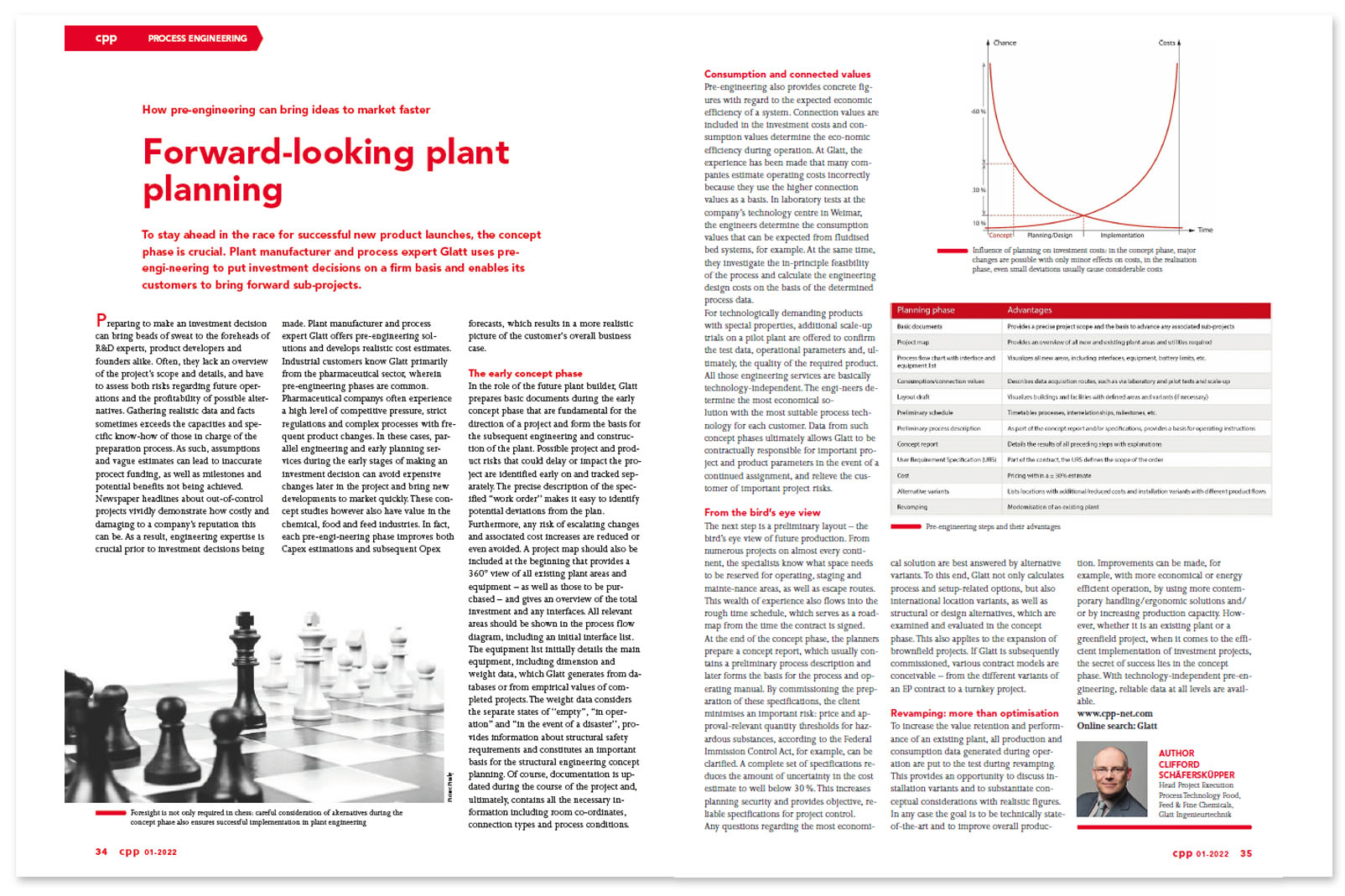

Published article: ‘Forward-looking plant planning – How pre-engineering can bring ideas to market faster’

To stay ahead in the race for successful new product launches, the concept phase is crucial. Plant manufacturer and process expert Glatt uses pre-engineering to put investment decisions on a firm basis and enables its customers to bring forward sub-projects.

» Author: Clifford Schäfersküpper, Head Project Execution Process Technology Food, Feed & Fine Chemicals, Glatt Ingenieurtechnik GmbH

» originally published in the magazine ‘cpp – chemical plants & processes’, issue 01/2022, Konradin Verlag Robert Kohlhammer GmbH

Basic Engineering and Extended Basic Engineering

In the Basic Engineering, we continue the concept planning for your project in a logical manner. We create an initial, self-contained, approvable documentation that implements your specifications and forms the basis for the execution of the project. Basic Engineering is carried out in close consultation with you. In addition to our proven standards for the scope of documents, your specific wishes are of course also taken into account. We use modern and compatible software tools to create the documents. For the greatest possible flexibility, we also make use of long-term cooperations with reliable partners, if required. Thanks to our international presence, we can access local employees of the Glatt Group or engineering partners with knowledge of local conditions for your project in order to reliably implement country-specific requirements in each case. In consultation with you, we provide the necessary support in obtaining official approvals for your project. For this purpose, we prepare the necessary approval planning for submission in consultation with you and the responsible authorities and accompany the approval process.

Selected customized services within the scope of Basic / Extended Basic Engineering in continuation of the Conceptual Design with the focus on, among others:

- process description

- process flow diagrams, P&I

- plant parameters

- mass balances, energy balances

- layout plans

- equipment specification

- pipe class definition

- safety analysis HAZOP, FMEA

- qualification QMP

- cost calculation

- project time schedule: specified time schedule of the whole project

- project management

Detail Engineering

In the Detail Engineering we prepare the final documentation of the implementation planning for your project. Thanks to the depth of detail, taking into account legal requirements, it serves as a precise guideline for the implementation of your project: starting with the tendering and procurement of all project-specific supplies and services through to the construction of the facilities. Of course, the Detail Engineering is also carried out in close consultation with you. Whether it is a question of the scope of planning or the level of detail, specifications or tender documents – we discuss every step with you. Together with you, we conduct workshops so that all supplies and services for the realization of your project can be tendered and procured in accordance with the project requirements and your specific needs. As an elementary component for an efficient cost and schedule management, all key data for the further technical and commercial project realization are thus created.

Selected services:

- specifications for machinery and apparatus engineering

- installation planning in 2D or 3D

- piping design in 2D or 3D including collision check

- insulation and corrosion protection

- electrical planning

- planning of measurement and control technology

- programming of control systems and instrumentation

- safety engineering

Approval Planning / Authority Engineering

New investments usually require official approval. For this purpose, sufficiently detailed but, above all, approvable documentation must be prepared and coordinated with the responsible authorities.

In order to obtain permits in accordance with the Federal Immission Control Act, information is required that is derived from environmental law, wastewater law or noise protection regulations, among other things. Checking public-law requirements is also part of the process, as are public hearings if necessary, so that the planned project at the site can be approved.

We support you in preparing the approval procedure, in coordinating the necessary documents in discussions with the responsible authorities and in preparing the application for approval.

We prepare the applications for you and/or accompany the approval phase. During the planning phase, we observe all relevant regulations such as the Hazardous Incident Ordinance, the Hazardous Substances Ordinance, the Technical Instructions on Air Quality Control, the Technical Instructions on Noise Control, the Odor Immission Directive, etc.

General Planning

As a general planner, we also support you with an extended planning scope. In addition to the technological process, your project also requires the conception and planning of ancillary systems for supply and disposal, logistics, building and building services – in short: the general infrastructure with interfaces. Our experienced specialist planners and professional interface management can also fully relieve you of this.

In the sense of a holistic project approach as general planner, our project teams of experienced project engineers for supply and building services trades provide all planning services with overall responsibility in cooperation with our technology experts and our efficient project management. Our service portfolio as general planner includes coordinated interface and collision management for general planning in 3D design for all planning trades up to technical clarification with suppliers – if desired, even up to turnkey implementation. Minimize your project risks and coordination efforts and benefit from holistic planning from a single source.

Published article: ‘Growing the German phosphate industry’ PDF, English

Published article: ‘Precision landing with special plant engineering – A statement by Dr. Viktor Drescher, Glatt Ingenieurtechnik GmbH’ PDF, German

Published article: ‘A Fluid Bed Approach – Case study on the economical production of urea-based fertilizers can be achieved using fluidised bed technology’ PDF, English

Published article: ‘Full Flexibility with Spouted-Bed – Glatt’s ProCell continuous spouted-bed equipment makes high-quality granulates and pellets’ PDF, English

Glatt Technical Paper: ‘Integrated approach saves costs – Design and operation of energy-efficient fluid bed systems’. PDF, English