Micro-encapsulation

Encapsulation from the liquid.

Combination of drying, granulation and release control in one step.

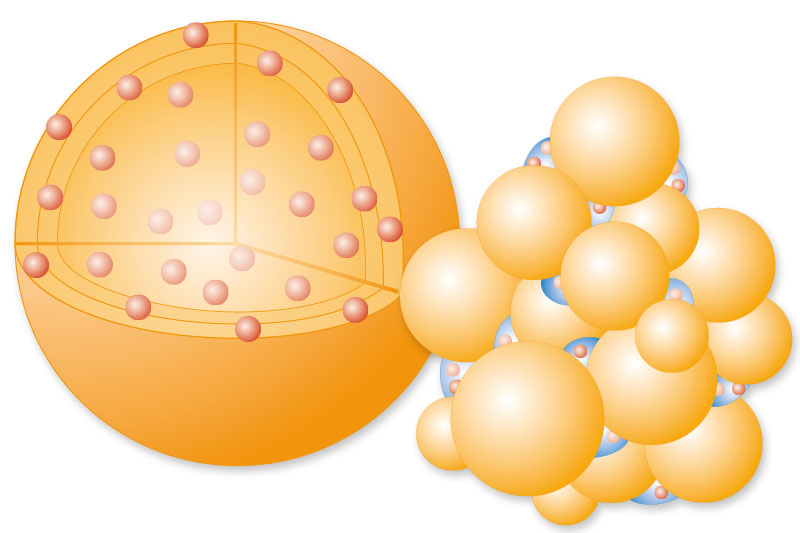

Microcapsules in solid matrix for perfect enclosure and protection of sensitive substances

Valuable substances that require special protection are often present in powder or even liquid form. This encapsulation process is used in particular for products and ingedients for the food industry. These include probiotics or essential oils, fragrances and flavors, for example. Micro-encapsulation in the fluid bed or spouted bed allows these substances to be embedded in matrix pellets, thus combining drying, granule formation and release control in a single step. The substances to be protected are emulsified and then gently granulated on the basis of spray granulation and thereby embedded homogeneously distributed in a compact protective matrix.

In the field of micro-encapsulation, Glatt has conducted various case studies on formulation and process optimization strategies based on encapsulation efficiency. Depending on the preferred principle, based on the properties of the customer’s active ingredients to be encapsulated, a wide range of available technical equipment can be customized in terms of cost, efficiency and formulation properties. In water-based matrix encapsulation, we focus on the solidification conditions as well as the crystallization behavior in lipid-based encapsulation, adapted to the particular material system for particle formation in fluid bed or spouted bed spray granulation processes.

The micro-encapsulation process is carried out in fluid bed and spouted bed systems, preferably in continuous operation.

Product properties and advantages of granules from micro-encapsulation by fluid bed or spouted bed at a glance:

Adjustable Active Ingredient Content

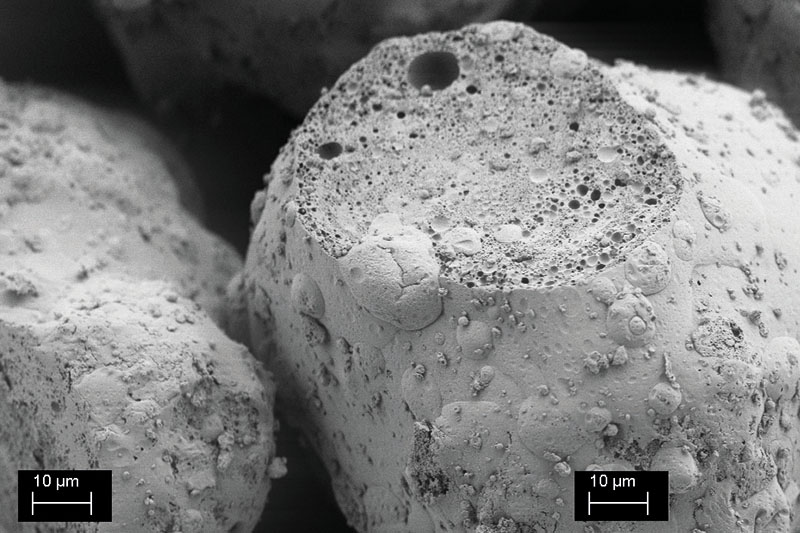

Dust-free, Round Pellets with Compact Structure

Porous Granules due to Loading of Solid Excipients

Various

Carrier Systems

Optimal

Functionalization

Excellent

Flow Behavior

Adjustable

Particle Size

Adjustable

Particle Size Distribution

Homogeneous

Component Distribution

Very Good

Dosability

Good

Solubility

Good

Dispersibility

Substances in powder form must be sufficiently well dispersed in the matrix liquid, or insoluble liquids must be emulsified. During subsequent spray granulation, the finely dispersed valuable substances are fixed in the solid carrier matrix.

As an alternative to encapsulation in homogeneous, compact matrices, the spray liquid can also be sprayed onto carrier particles. Suitable base materials include application-compatible powders or inert carrier granules. The particle structure can be adjusted to meet specific requirements by varying the formulation and the process parameters.

Granules and pelltes produced by micro-encapsulation score – just like products from spray granulation – with properties such as high abrasion resistance, very good flowability, good solubility or optimum dosability. The dust-free granules have a dense surface structure and high bulk density, and their reduced surface area makes them less hygroscopic. Parameters such as particle size, residual moisture and solids content can be specifically influenced to achieve a wide variety of product properties. Due to their often round shape, the granules are also very suitable for subsequent coating for further functionalization.

Product examples for micro-encapsulation

Lavender oil, micro-encapsulated

Orange oil, micro-encapsulated

Beta carotene, vitamins, micro-encapsulated

PUFA (Polyunsaturated Fatty Acids), micro-encapsulated

Granules with micro-encapsulated oil, REM

Here you will find many more product examples for applications in various industries for food, food additives, food supplements, feed additives, additives and components for cosmetics, detergents and cleaning agents, as well as products from the field of agrochemicals.

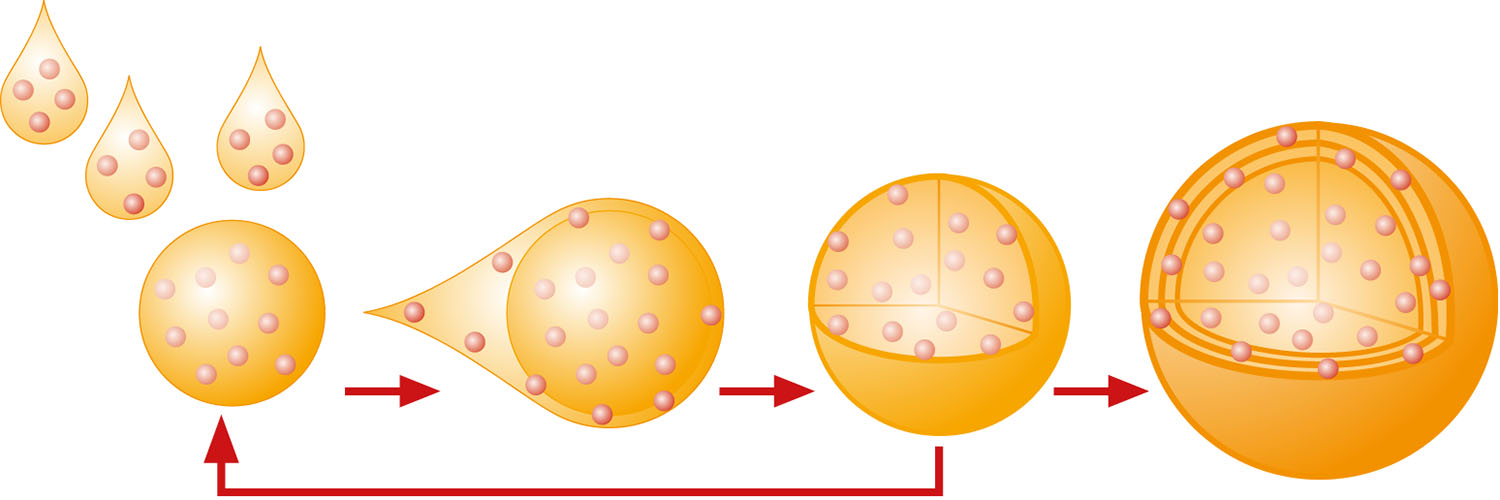

The process of micro-encapsulation based on spray granulation in detail

Liquids containing solids, such as solutions, suspensions or melts, are sprayed into a fluidized bed or spouted bed. Due to the high heat exchange, the aqueous or organic solvents evaporate or vaporize immediately, and the solids form small particles as carrier cores. These are wetted with further liquid, which in turn form a solid shell around the carrier core after drying. This process is repeated. The granules grow homogeneously in layers. No separate feed of raw materials is required. Alternatively, a defined quantity of suitable carrier cores can be supplied.

If various starting materials are mixed in the liquid phase and then spray granulated, granules are produced in which the starting materials are very uniformly distributed. If the process is set up correctly, liquids can also be enclosed in a matrix in this way. Sensitive substances can thus be well protected.

Protection of sensitive active ingredients by micro-encapsulation based on spray granulation

Protection of sensitive active ingredients by means of micro-encapsulation based on spray agglomeration

Glatt Continuous spray granulation in the fluid bed,

example: top spray process

From the product idea to production

Since micro-encapsulation processes start with the preparation of the liquid, we support our customers in developing the formulation and liquid preparation. The liquid can then be produced in a plant test at our technology center. Starting from laboratory scale, the product can be verified in pilot plants. Reliable scale-up enables the development of finished solutions on an industrial scale.

Volatile substances and oxygen-, moisture- or temperature-sensitive ingredients are a challenge for fluid preparation and processing. To overcome these challenges, we can change both the acting fluidization medium (nitrogen) and the process gas flow management (closed loop). We can also process liquids at gentle production temperatures (40°C) without negatively affecting the properties of the final product.

Through contract manufacturing at Glatt, your new powders, pellets or granules can be manufactured, filled, packaged and delivered directly in agreed quantities. As a plant manufacturer, Glatt provides all services from project initiation, development and realization through to turnkey production in your own plant.

Further information on the topic of micro-encapsulation in the fluidized bed and spouted bed can also be found in the following publications:

Published article: ‘How to Tame Recalcitrant Ingredients with Technological Processes’ PDF, English

Published article: ‘The gentle processing of highly volatile oils by fluid bed and spouted bed technology’ PDF, English

Published article: ‘Spray (micro)encapsulation of sensitive substances in matrix form – An overview of essential oil and vitamin case studies’ PDF, English

Published article: ‘Customised enzymes for optimal animal feed mixes’ PDF, English

Published article: ‘A matter of gas flow management – Microencapsulation of essential oils by spray granulation unsing spouted bed technology’ PDF, English