Glatt at the Weimar site, Germany, October 2022: Office buildings and Technology Center

Glatt Technology Center Weimar

Unique platform for particle design and particle engineering

Take advantage of Glatt’s know-how in feasibility testing, product sample production, scale-up and contract manufacturing to give you a head start in the market!

With this forward-looking technology center, Glatt has created an attractive platform for experts, developers, manufacturers and scientists. With a focus on innovative particle design, ideas for products of a new generation become reality here. With us, you can develop functionalized material structures for high-performance powder materials with previously unavailable combinations of properties and refine your powders and liquids into customized, functional granules and pellets.

You will find optimal conditions when it comes to optimizing product properties: better bioavailability, flowability and freedom from dust, improved solubility, tabletable agglomerates, pellet formulations with functional coating, controlled-release spraying of active ingredients, extracts with solvents, drying of solvent-containing products, microencapsulation of volatile and sensitive substances.

Side by side with you, we perform feasibility studies and generate product samples. We investigate the influences of formulation and product properties and develop the optimal process. For the production of larger quantities that you need for marketing studies or a faster time to market, we offer contract manufacturing on our very flexible fluid bed and spouted bed systems. Typical campaign sizes are in the low to mid double-digit ton range.

Due to the growing demand for innovative technology solutions, our technology center has already been expanded several times. With innovative technologies for the production of powders, granules and pellets, our competence center offers you the opportunity to develop novel product forms or to optimize the properties or manufacturing processes of already established products in trials. For these studies, apparatus and plants of various sizes – from laboratory to pilot and production scale – are available.

Modern laboratories allow comprehensive analysis of your products. Feasibility tests on fluid bed and spouted bed laboratory equipment are also possible under GMP conditions.

Laboratory Systems

Lab scale for

calcination, drying, granulation, micro-encapsulation, coating, and …

With product quantities ranging from a few grams to a few kilograms, we conduct feasibility tests on a small scale.

Pilot Plants

Pilot scale for

calcination, drying, granulation, micro-encapsulation, coating, and …

Small-scale investigations on high-performance pilot plants for meaningful and safe transfer from laboratory to production scale.

Production Plants

Production scale for

calcination, drying, granulation, micro-encapsulation, coating, and …

Modular, large-scale installations are available for initial production campaigns as well as for longer-term contract production.

Complementary Equipment

Full range for successful product design with an integrated approach to the development process

Depending on the application, it makes sense to intelligently link different processes. Here, it is important to coordinate the individual steps.

Preparation of Raw Materials and Products

Stirring. Dispersing. Dissolving. Suspending. Homogenizing:

Perfect preparation for the success of subsequent processes

For the special production and preparation of liquids, our technology center has a wide range of equipment.

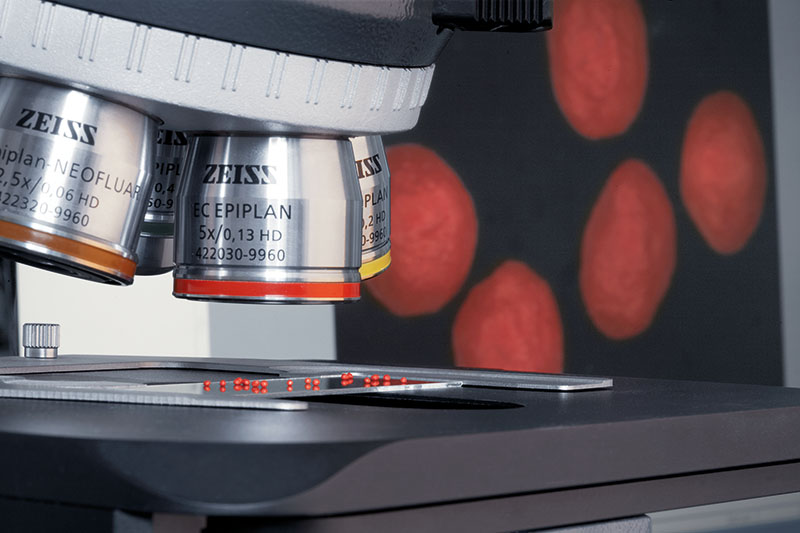

Analytic Labs

Characterization of materials and substances as well as determination of the properties and compositions of your products

We combine modern analytical equipment for focused, granule- and powder-specialized analysis with your methods and product-relevant specifications.

The network for research and development

Our Technology Center at the Weimar site is networked with renowned scientific institutions such as universities and research institutes in Germany and abroad. Through continuous research and development work in process engineering, for calcination, granulation and drying of powders and liquids containing solids, and for particle coating by means of technologies such as powder synthesis, fluidized bed or spouted bed, we are now able with our equipment to develop and optimize products whose processing was hardly possible just a few years ago. In this way, we offer our international customers from a wide range of industries access to innovative technologies for their processes.

Combination of process diversity and state-of-the-art equipment technology

The Glatt Technology Center in Weimar is a competent hub for continuous and batch processes. The combination of process diversity and state-of-the-art equipment technology enables classic and customer-specific applications of a wide variety of processes. For this purpose, we have a wide range of innovative synthesis reactors as well as fluid bed and spouted bed systems at our disposal. Complementary equipment such as extruders, pelletizers or tablet presses as well as modern analytics complete the range.

Glatt’s technology site in Weimar is embedded in an excellently thought-out local infrastructure: from raw material delivery to the provision of end products.

Solutions for your competitive edge. This is our daily challenge.

Benefit from a powerful concept of expert know-how, technology transfer, flexible process and site conditions and excellent, comprehensive service!

Further information on this topic can also be found in the following publications:

March 2022: Glatt expands technology center with new laboratory plant for powder synthesis

September 2021: New fluid bed options for solvent-based processes and products

March 2021: Glatt Ingenieurtechnik celebrates continued business success with third expansion of its Technology Center

Brochure A4: Glatt Technology Center Weimar, PDF, English

Brochure A4: Glatt Functionalization of granules and pellets, PDF, English