Glatt Laboratory Units

Testing of fluid bed, spouted bed and rotor processes.

Glatt ProCell® LabSystem at the Glatt Technology Center, Weimar, Germany

Customized product development in your laboratory

Innovative processes for the development and production of high-quality and functional granules and pellets require individual solutions. This already starts with testing in the laboratory. The market and legislators are placing ever higher demands on technology, efficiency and safety, as well as documentation. It is important to be fast and cost-efficient on the market with innovative products.

Use our well-equipped technology center for this purpose or develop and optimize your own manufacturing processes in your own laboratory. You will receive initial test batches as a basis for reproducible results on an industrial scale later on. Test fluid bed, spouted bed and rotor processes. With innovative Glatt technology, in intelligent Glatt design.

Strong arguments for your lead in the market. For all needs and requirements.

Reliable test results

in reproducible quality

Reproducible quality of your products even with the most complicated processes.

Compact & ergonomic design

for top handling

Functional design. All-round ease of operation. Lightning-fast component changes. Simple cleaning. Maximum efficiency.

Modular & individually configurable

for full flexibility

Modular design and flexible configurability for a fast and effective response to changing requirements.

Intelligent control solutions

for easy process control

Intuitive operator guidance. Automated control systems comply with GAMP guidelines. Reliable process control. Sustainable plant availability with long-term support.

Safety concepts to protect people,

products and environment

Tried-and-tested RABS and isolator technology. Pressure surge resistance for closed systems. Safety concept with a globally unique standard.

GMP-compliant design for

optimal production of clinical samples

All components of our laboratory systems meet GMP conditions. All the prerequisites for efficient validation, qualification, and documentation on request.

Process inserts: (1) ProCell® 5, (2) ProCell® 10, (3) AGT 2, (4) GF 5, (5) Vario 3, (6) Vario 7, (7) Rotor 7, (8) Shovel rotor

Glatt ProCell® LabSystem

Our mobile all-rounder for maximum flexibility on a laboratory scale.

A modular system is available for feasibility trials with your product. Eight different process inserts allow top spray, bottom spray and Wurster coating for fluid bed, spouted bed or rotor processes in continuous or batch operation. Whether it is spray granulation or encapsulation of liquids, agglomeration of powders, powder coating or coating of particles: Everything is possible.

Mini-Glatt / Midi-Glatt

Our classics for all batch fluid bed processes for testing agglomeration, drying, and coating processes. Ideal for minimum batch sizes from 2.5 to 1,300 grams. Bottom and top spray processes. Can be flexibly retrofitted if required.

GPCG 10

Our modular all-rounder for all batch fluid bed processes and demanding scale-up on a pilot scale: from simple drying through granulation/agglomeration to coating and pelletizing. No matter whether top spray, bottom spray or tangential spray – whether Wurster coating or production of micropellets with the patented CPS process. A flexible all-rounder for your individual needs. Ideal for batch sizes from 2 kg to 25 kg.

Further information on this topic and related topics can also be found in the following publications:

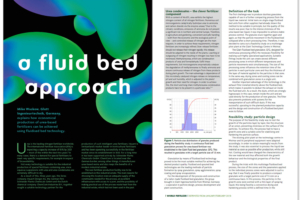

Published article: ‘A Fluid Bed Approach – Case study on the economical production of urea-based fertilizers can be achieved using fluidised bed technology’ PDF, English

Published article: ‘Optimizing end products with finely tuned process parameters’ PDF, English

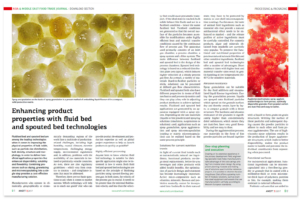

Published article: ‘Enhancing product properties with fluid bed and spouted bed technologies’ PDF, English

Published article: ‘Hot-melt applications for the food and beverage industry – How to safely stabilize vitamins and probiotics’ PDF, English

Published article: ‘Shaken or Stirred – Agglomeration with fluidized bed technology’ PDF, English