Process Environment and Handling

Clever symbiosis between solids, liquids and gases for optimum product results

Sieve, contract manufacturing, dietary supplements, food ingredients, Germany

Sophisticated solutions for the handling of process media

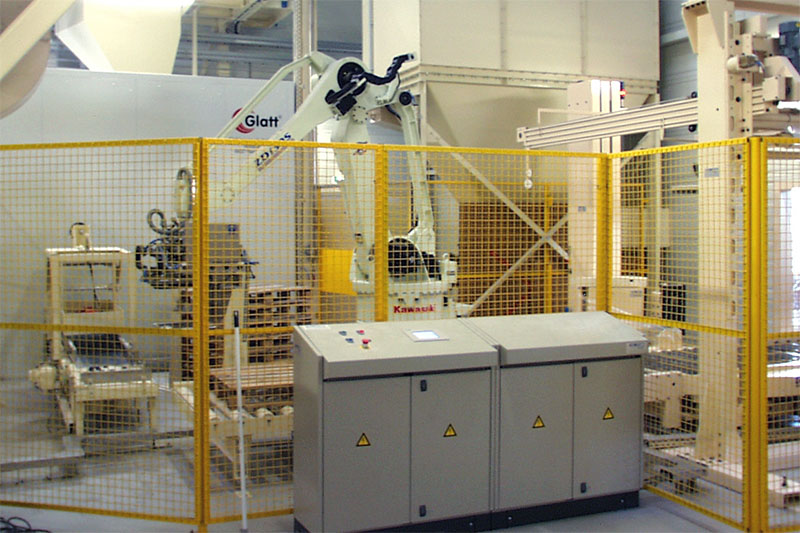

No process can be operated on a production scale without raw material and end product handling tailored to the product.

At your request, we can provide you with everything from a single source. Additional equipment for upstream and downstream processes can also be included in the planning and scope of supply.

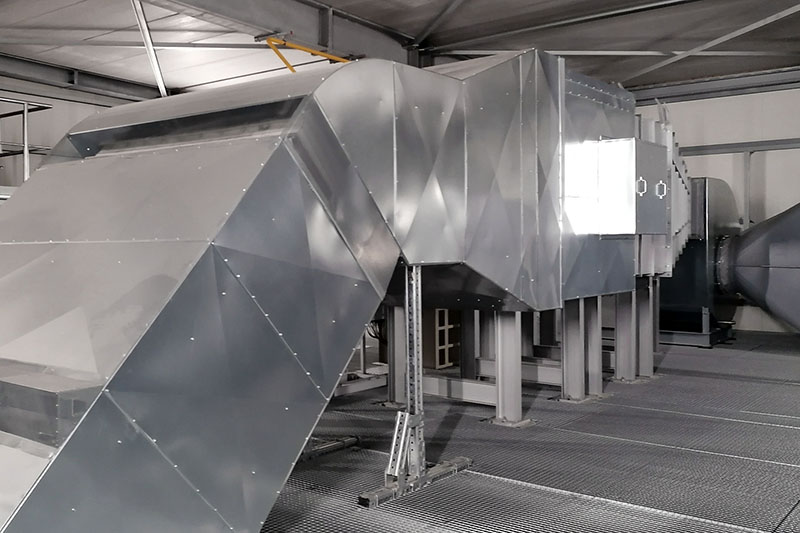

In the upstream and downstream around the actual process, we plan and supply raw material handling systems such as bag chutes, big bag discharge stations, screening, grinding and dosing systems as well as preparation systems for the liquids to be processed. This also includes the necessary installations for modern hotmelt processes, suitable transport systems such as pneumatic conveying, bucket elevators, conveyor belts or vibratory conveyors, for example with integrated product tempering.

For the product, we offer transport systems, storage silos and packaging systems such as bagging systems, drum filling or big bag packaging. If desired, the entire plant can be equipped with a central dust removal system.

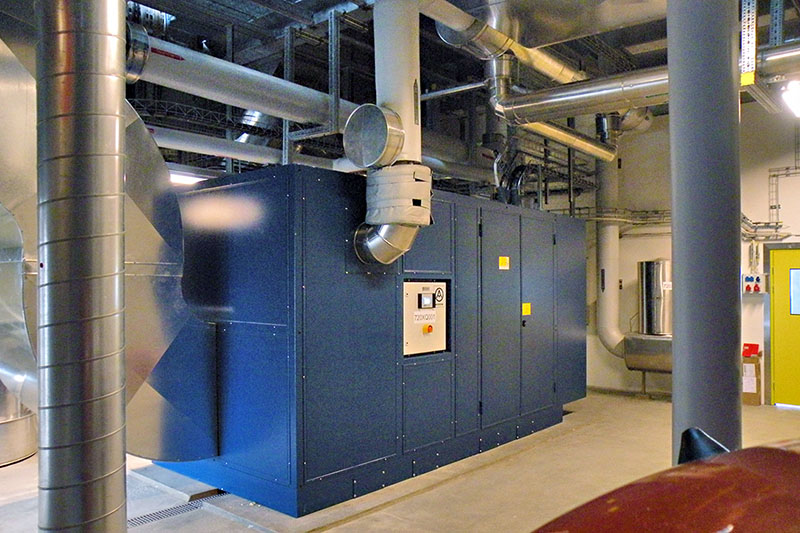

We also offer additional systems for the process gas, such as extended supply air treatment, additional waste gas purification for odor control, and heat recovery. In cycle gas systems, the complete compressed gas requirement can be generated from the cycle gas. For fresh air exhaust systems, we provide the compressed air for atomization.

Cleverly designed process environment for safe operation

Taking into account the local conditions, we design and supply modern and chemically resistant operating platforms. In this way, we adapt the entire plant handling to the local conditions. In addition, we can also incorporate building planning, including storage. We create a space concept that optimally adapts to the process requirements, operation and material flow.

This means for you

- easy and safe access to all equipment

- short distances for operating personnel

- optimal transport routes for raw materials and products

You get all this from a single source.

Preparation of suspension

Weighing-in

Personnel airlock

Big bag emptying

Packaging

Operating platform

Discharge

Dedusting

High-bay warehouse

Heat recovery

Inlet air supply system

Process air supply system

Air conditioning/ventilation technology

Control cabinet room

Ash silos

Acid tanks

Water treatment plant

Material lock

Here you can find more photos: Installed plants.

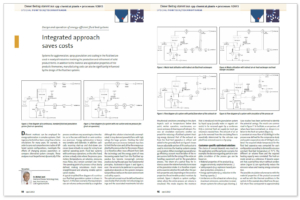

Further information on this topic and related topics can also be found in the following publications:

Published article: ‘Integrated approach saves costs – Design and operation of energy-efficient fluid bed systems’ PDF, English

Published article: ‘Full Flexibility with Spouted-Bed – Glatt’s ProCell continuous spouted-bed equipment makes high-quality granulates and pellets’ PDF, English

Published article: ‘Product safety for granulation and coating – Hygienic design for fluid bed and spouted bed systems’ PDF, German

Published article: ‘Atex-compliant system design for high process reliability’ PDF, German

Published article: ‘Cleanly separated – filters in fluid bed systems, an overview’ PDF, German