Technical Papers Published by Glatt for Download

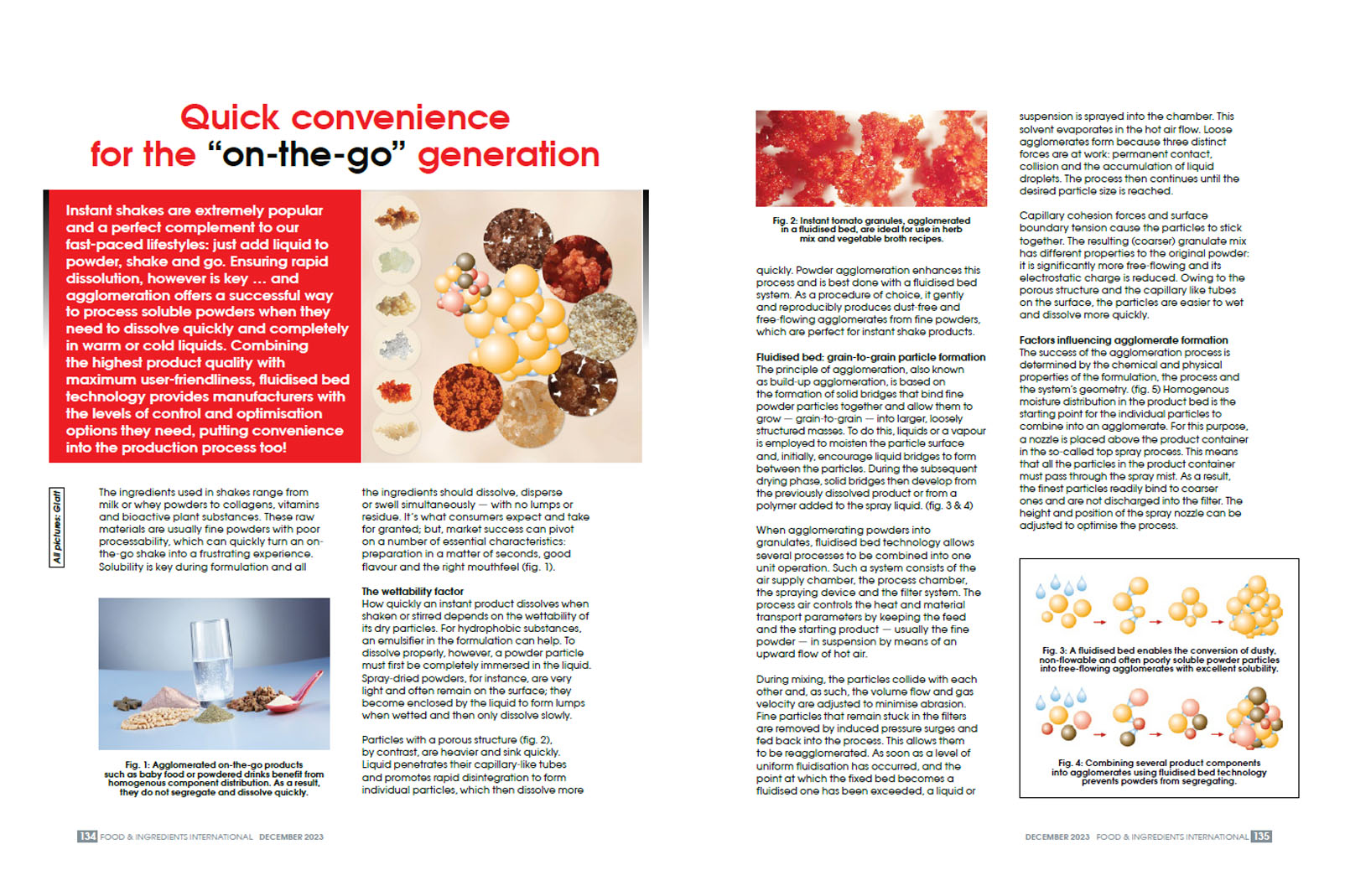

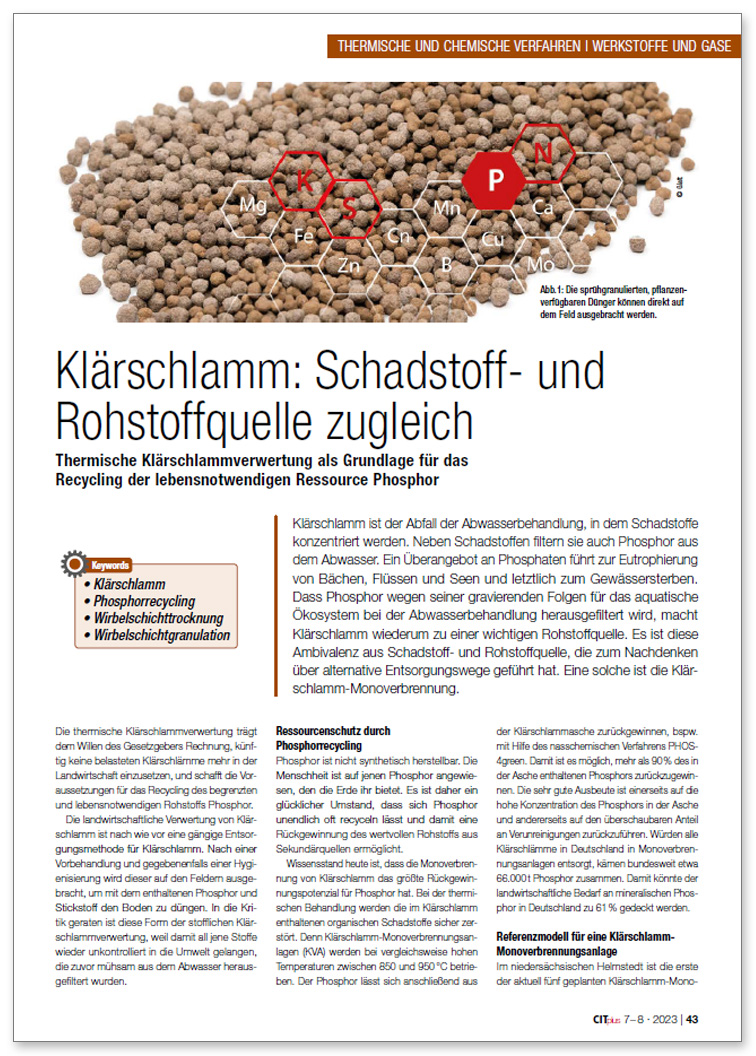

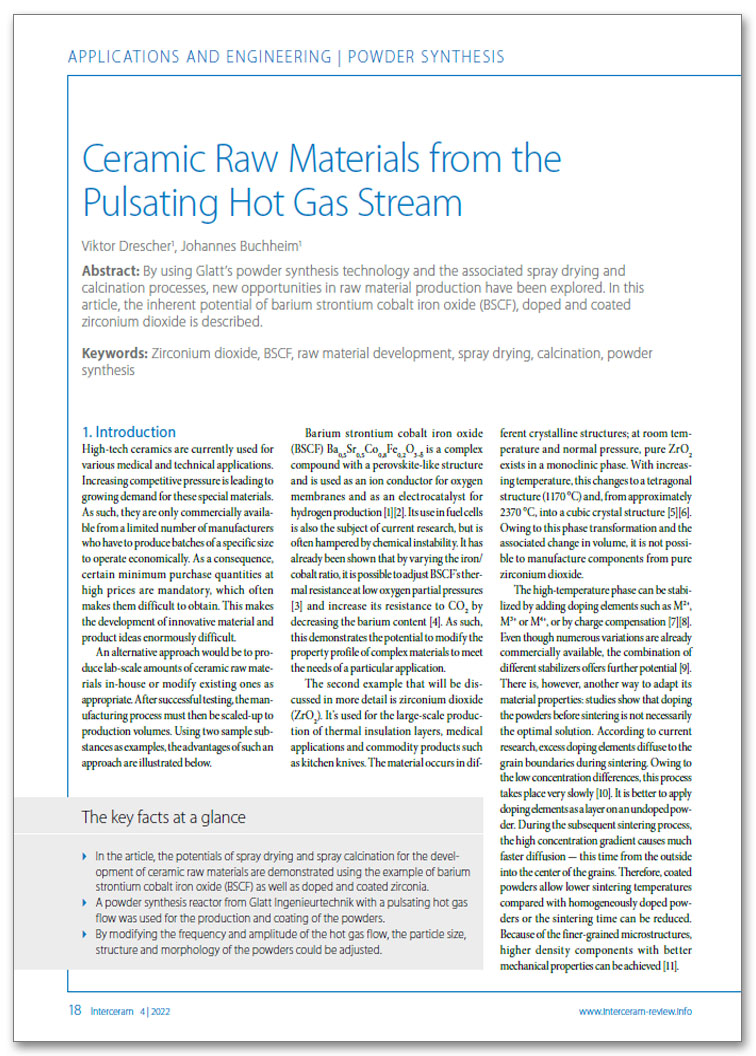

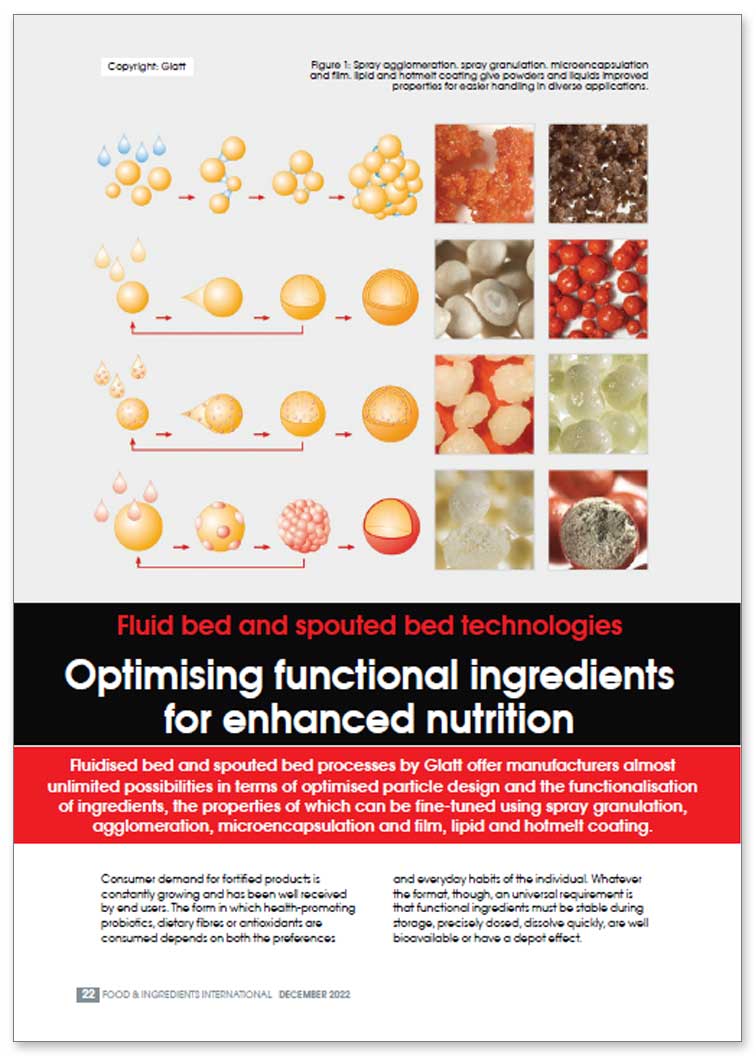

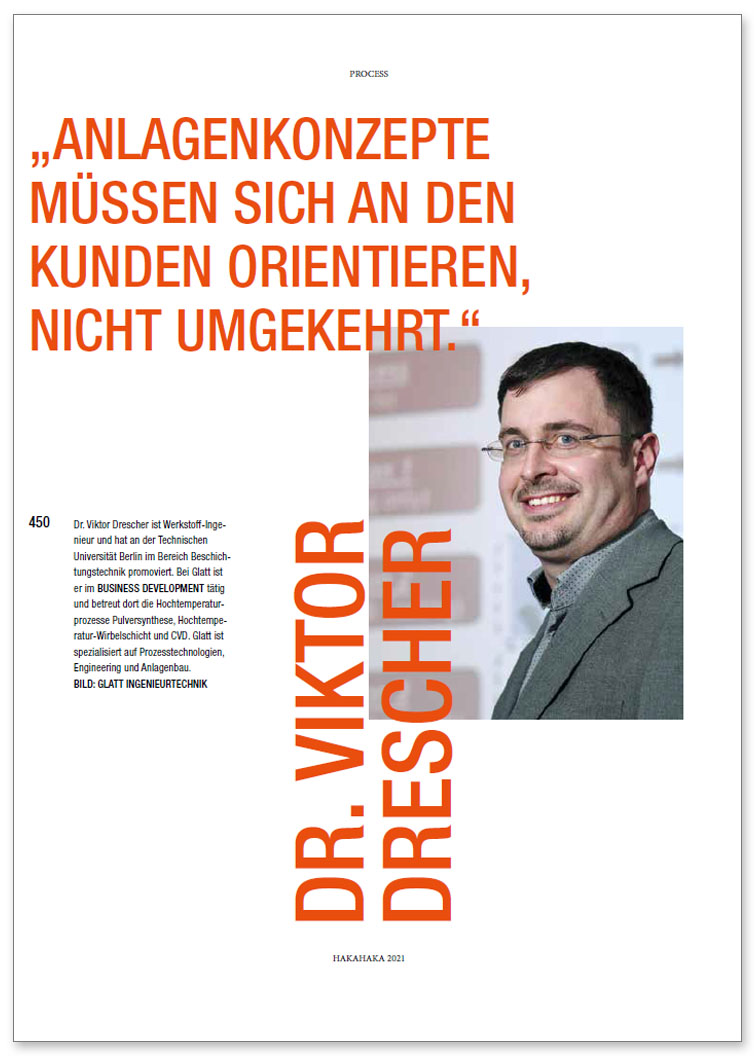

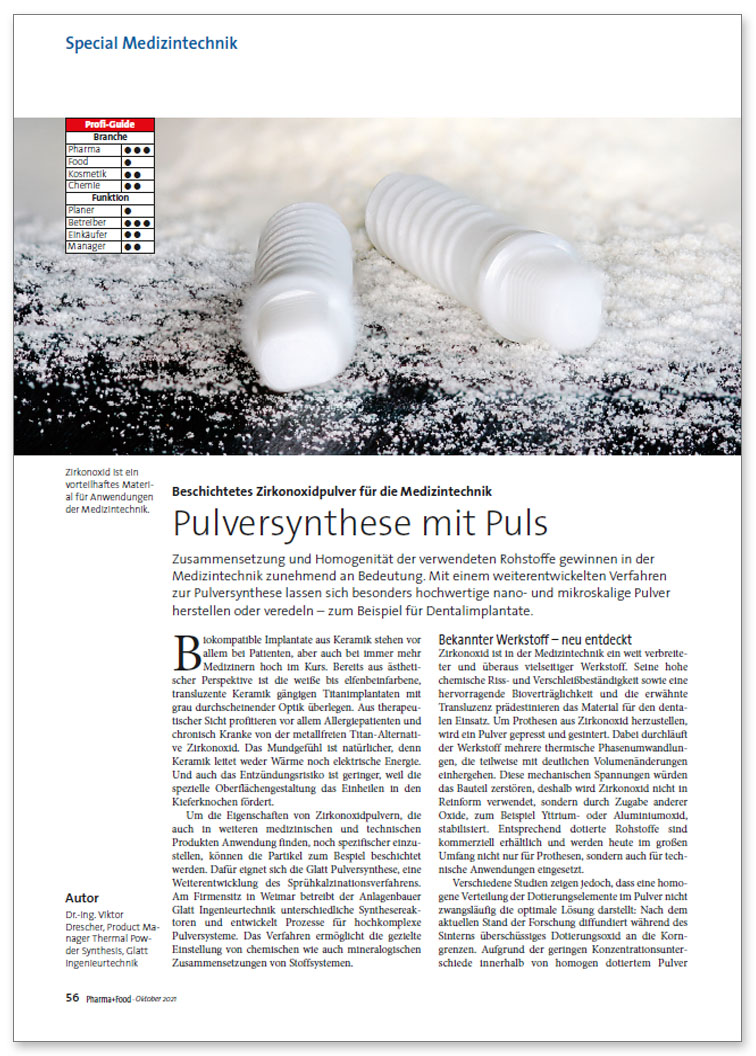

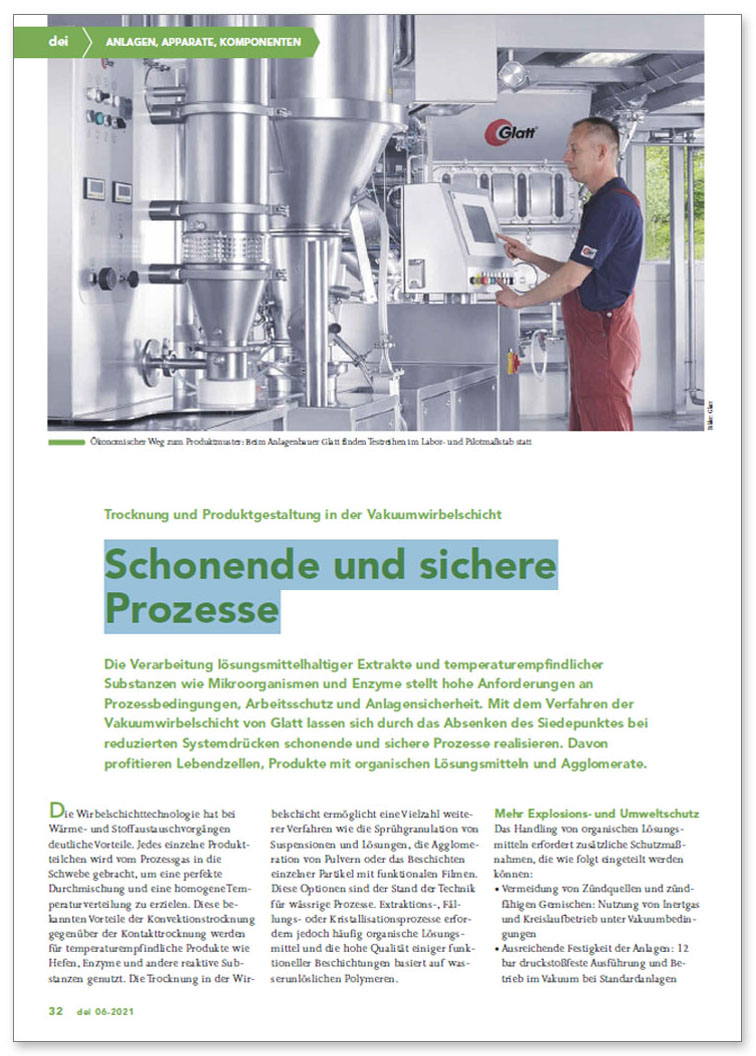

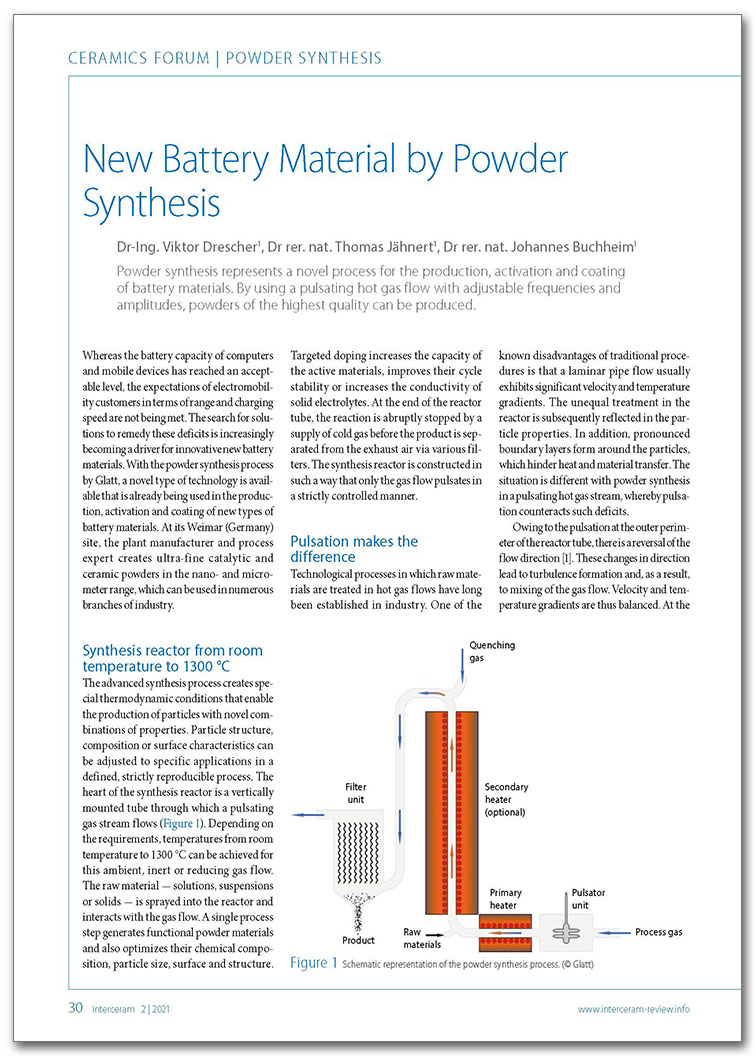

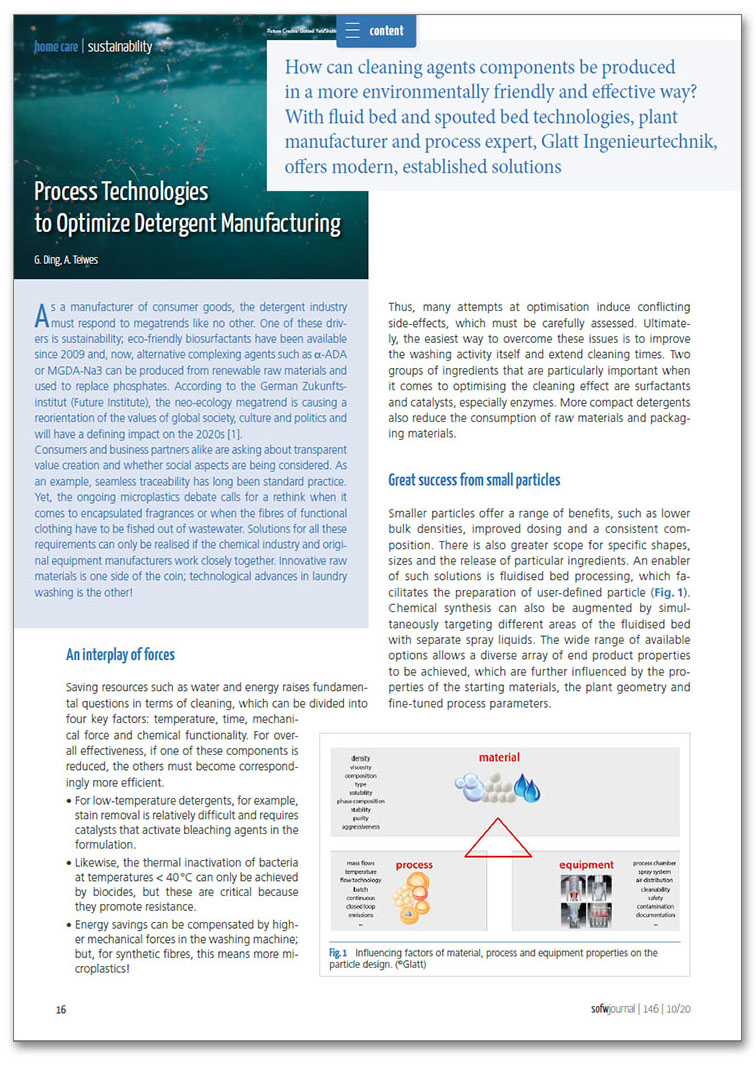

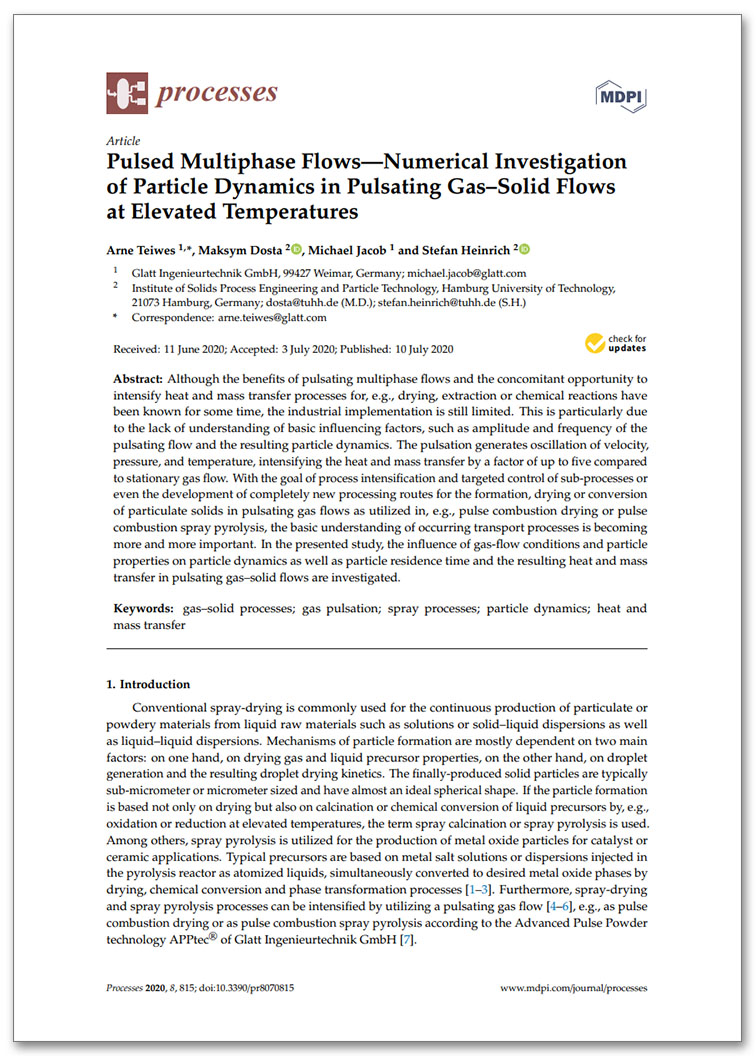

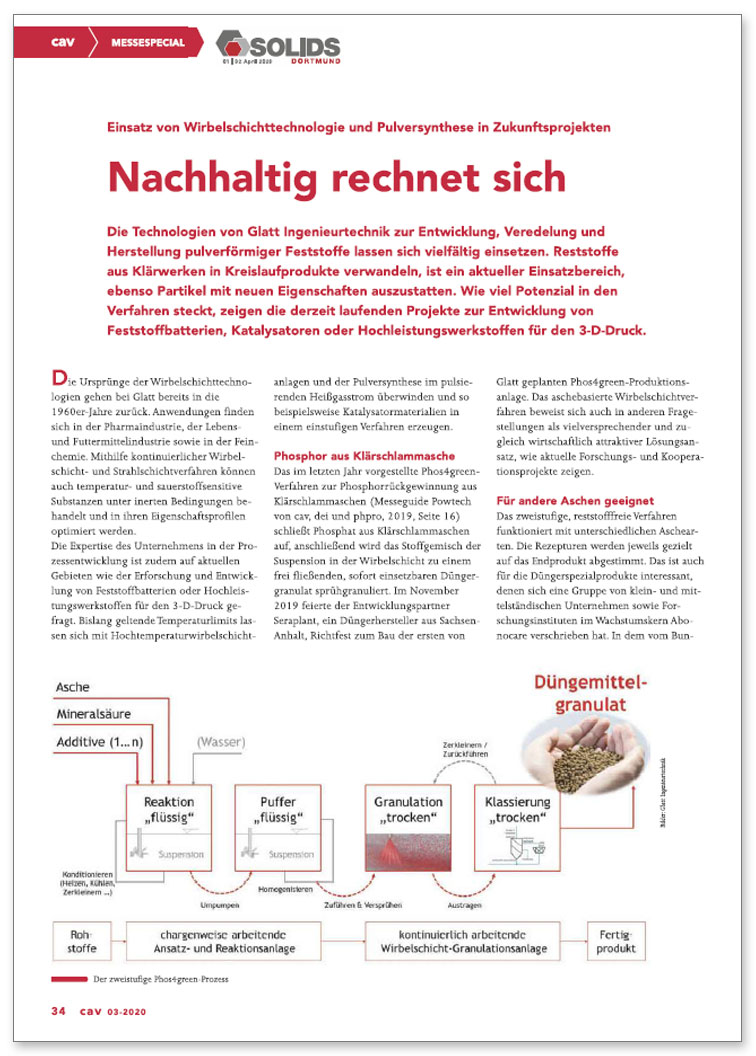

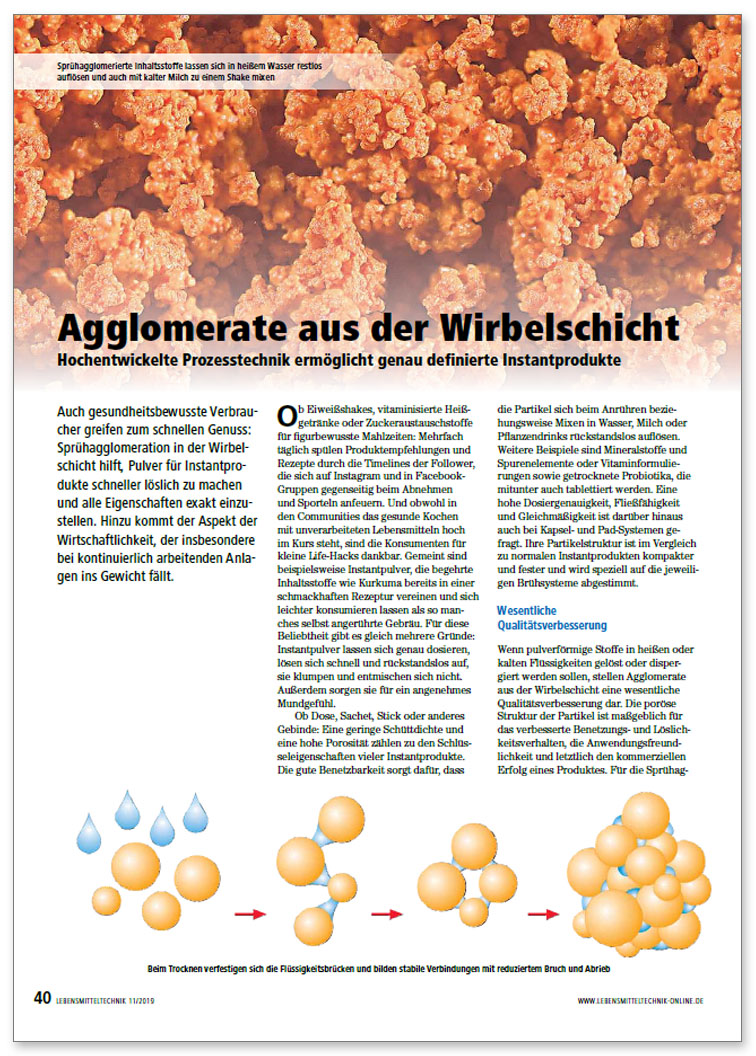

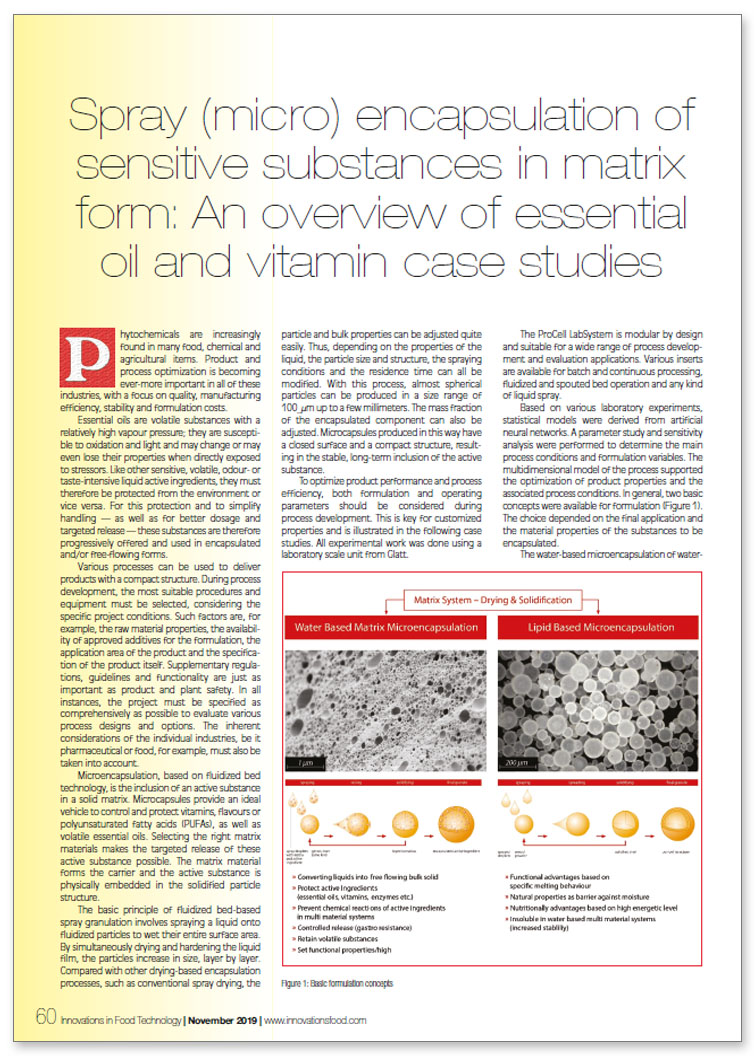

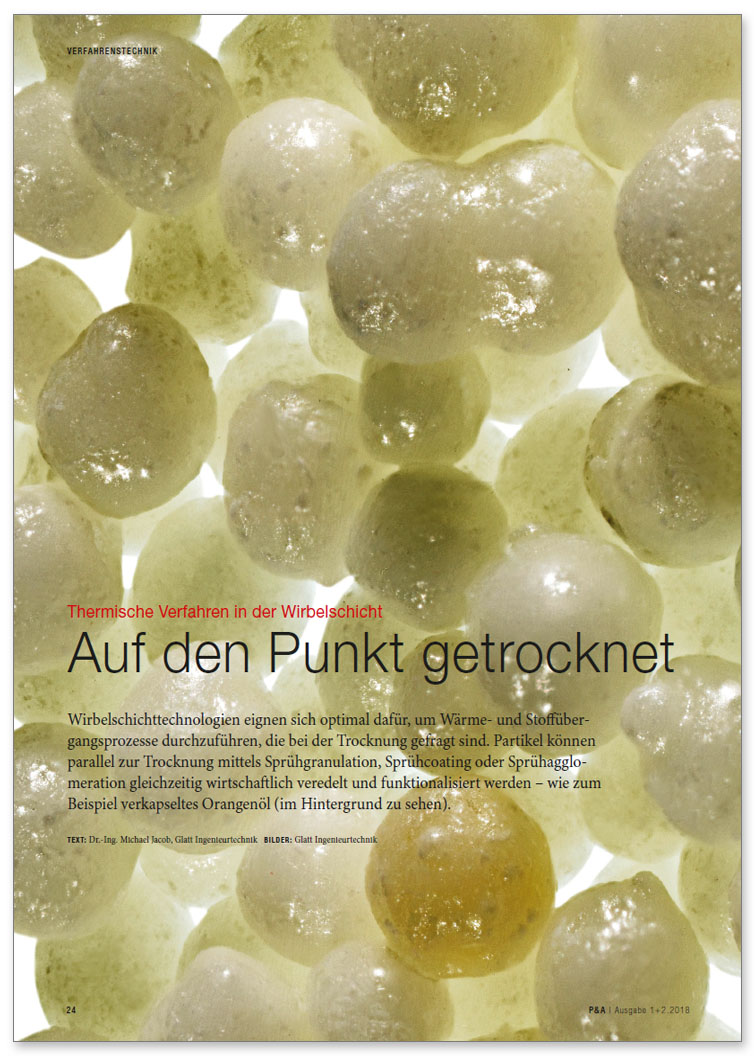

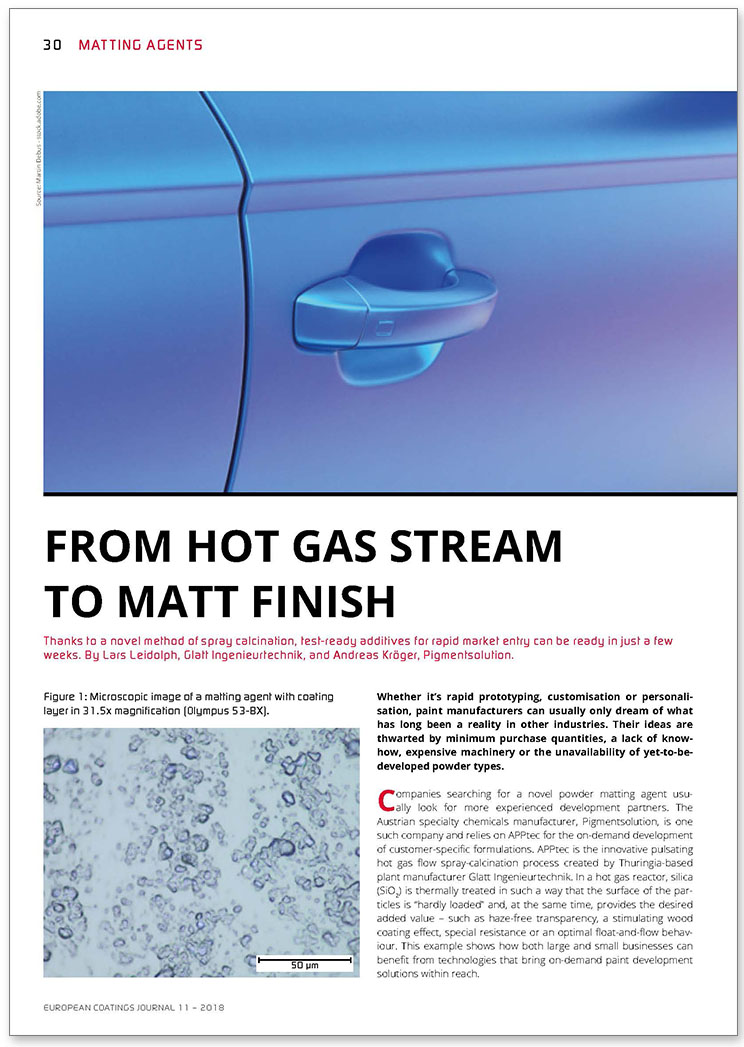

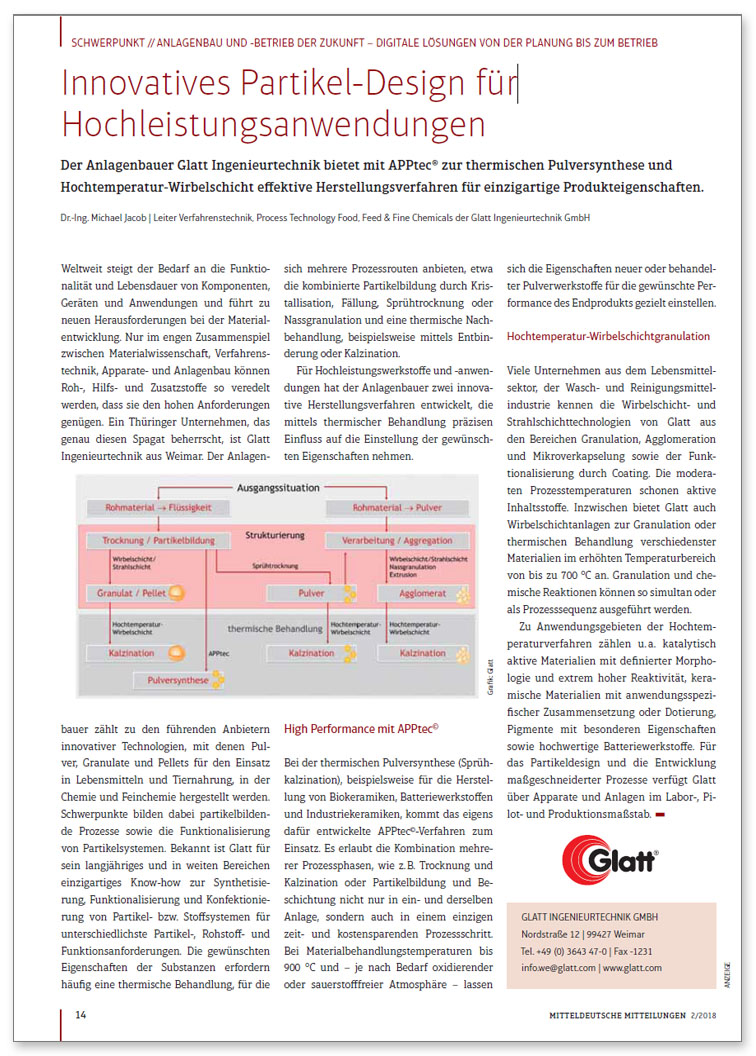

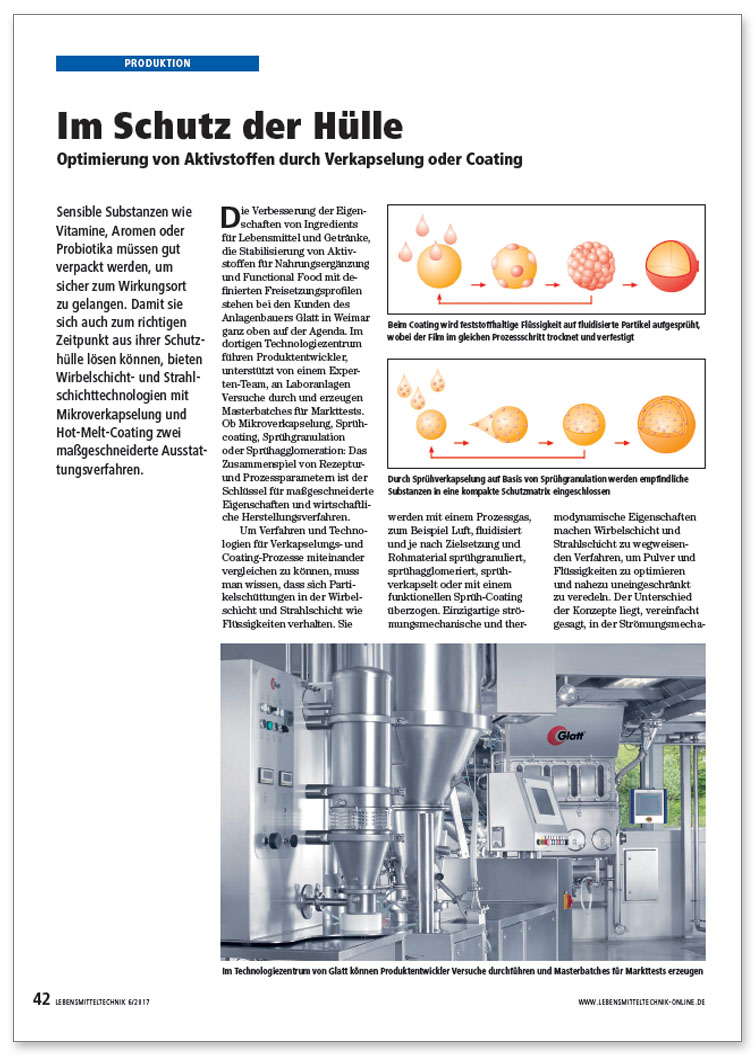

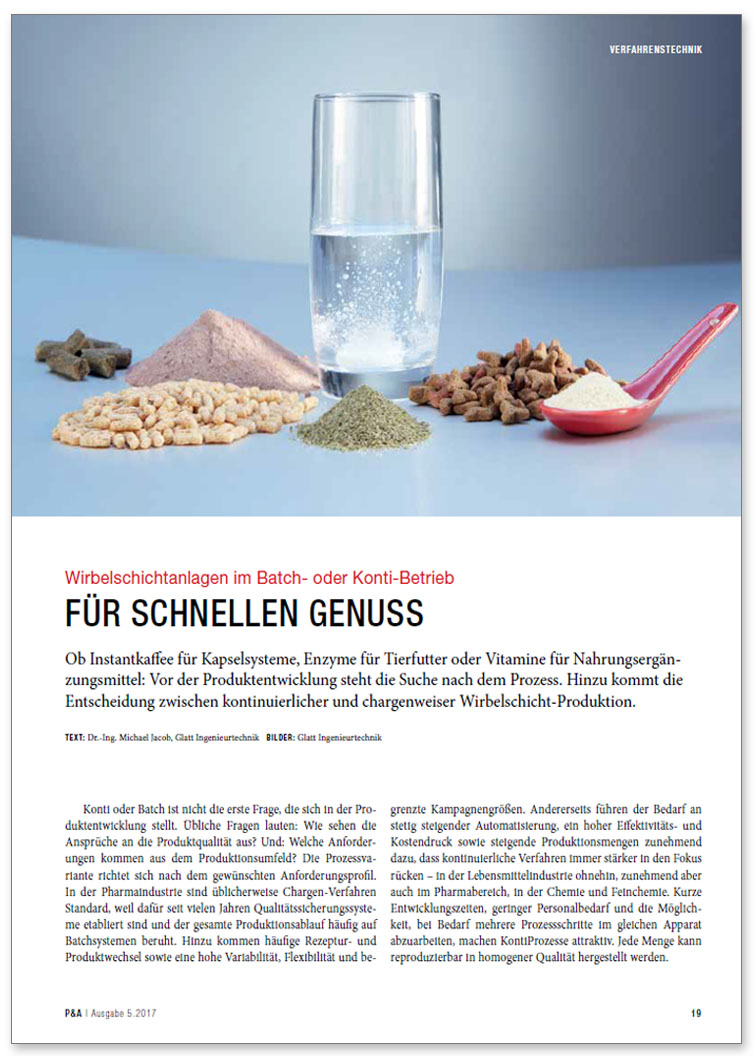

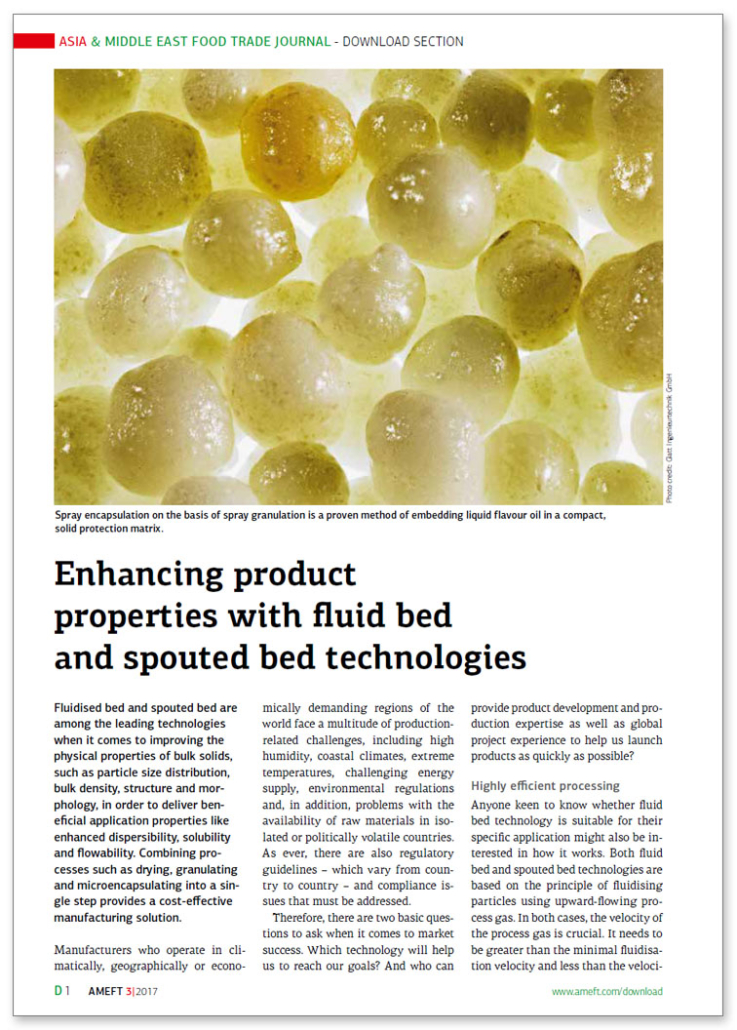

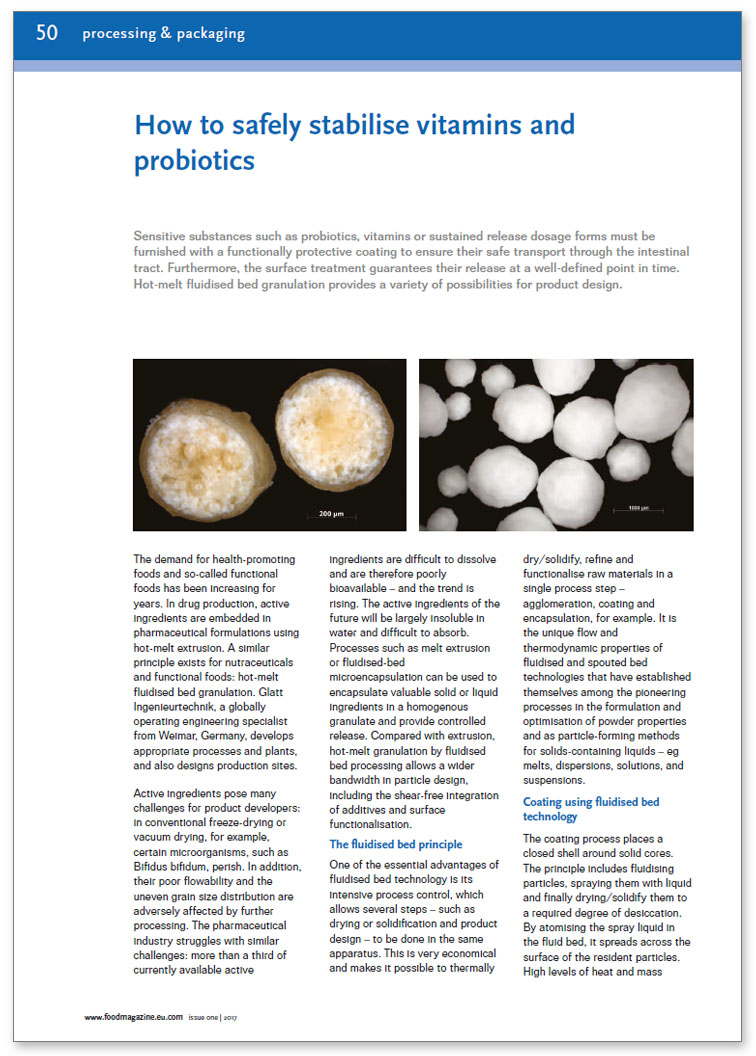

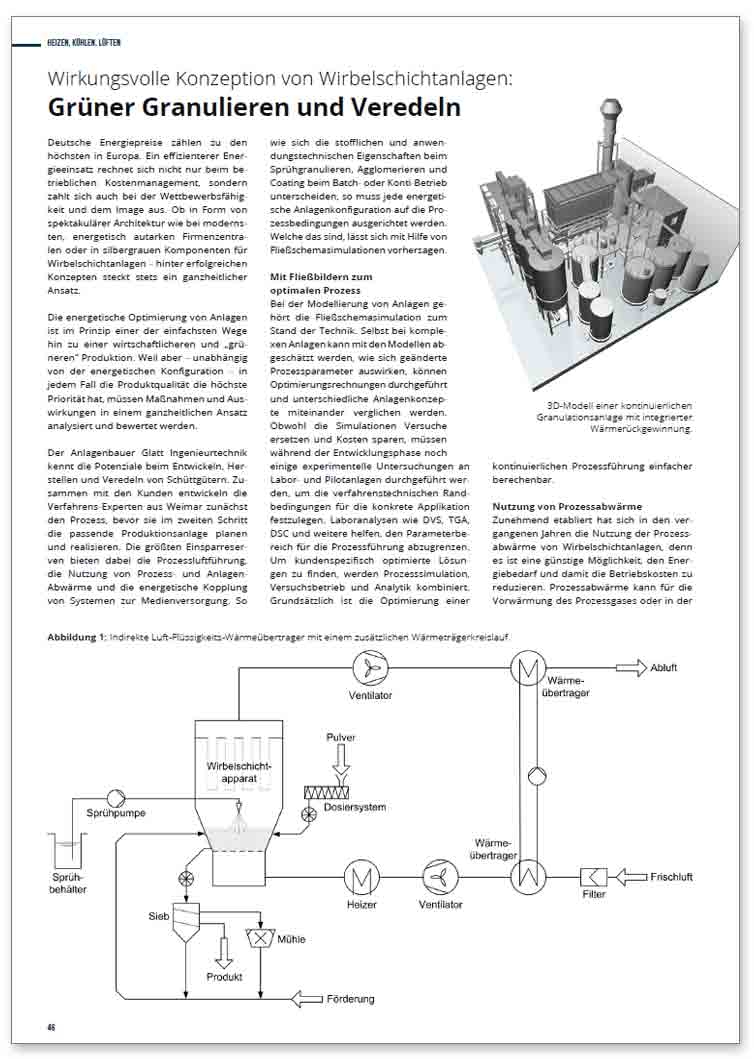

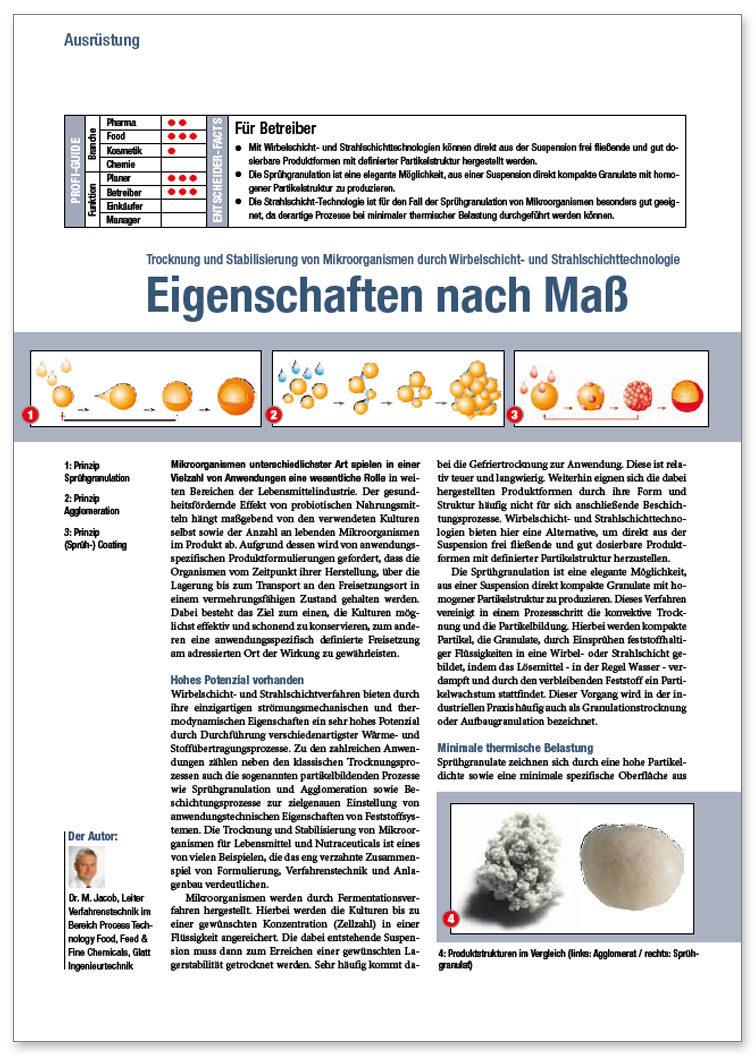

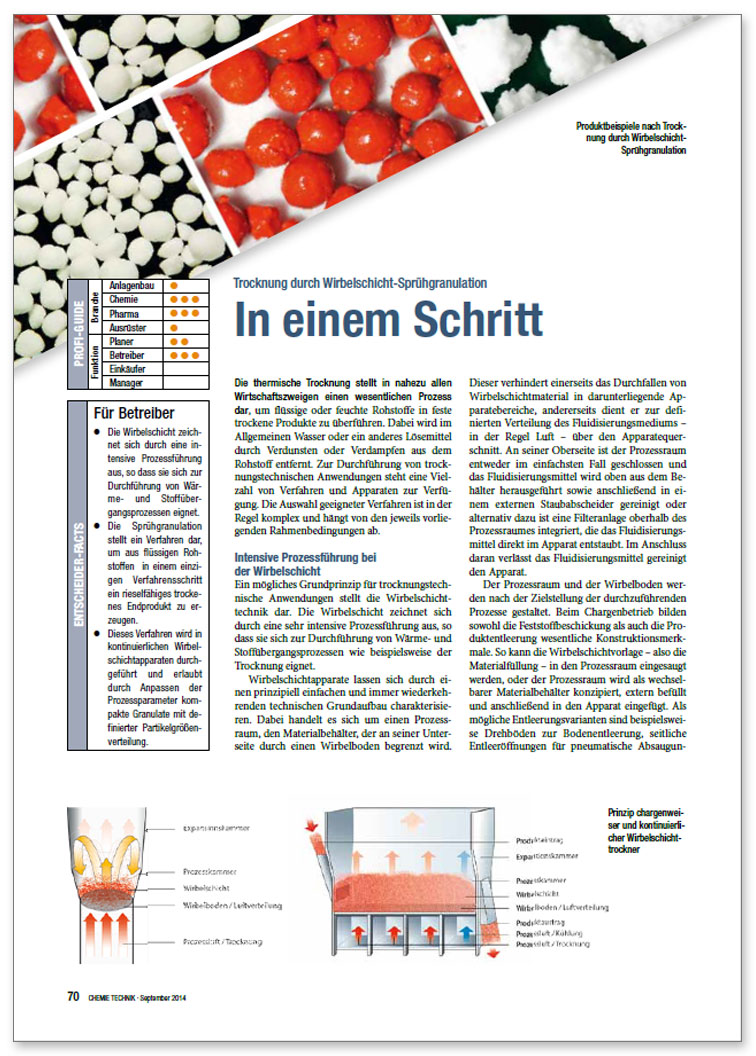

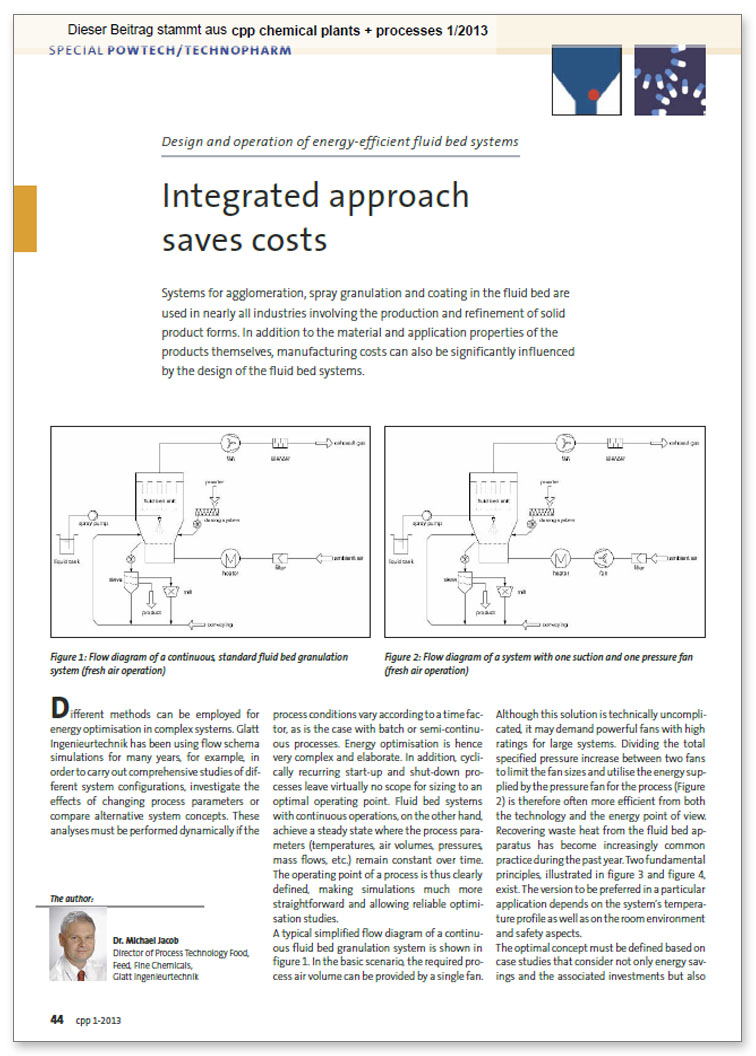

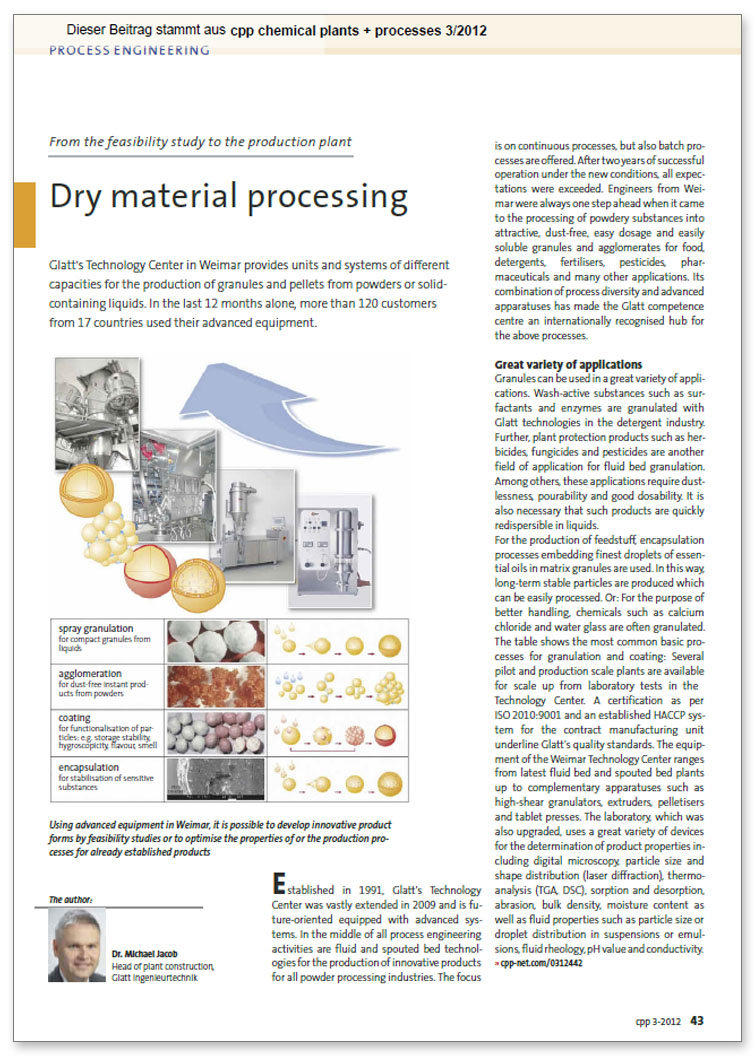

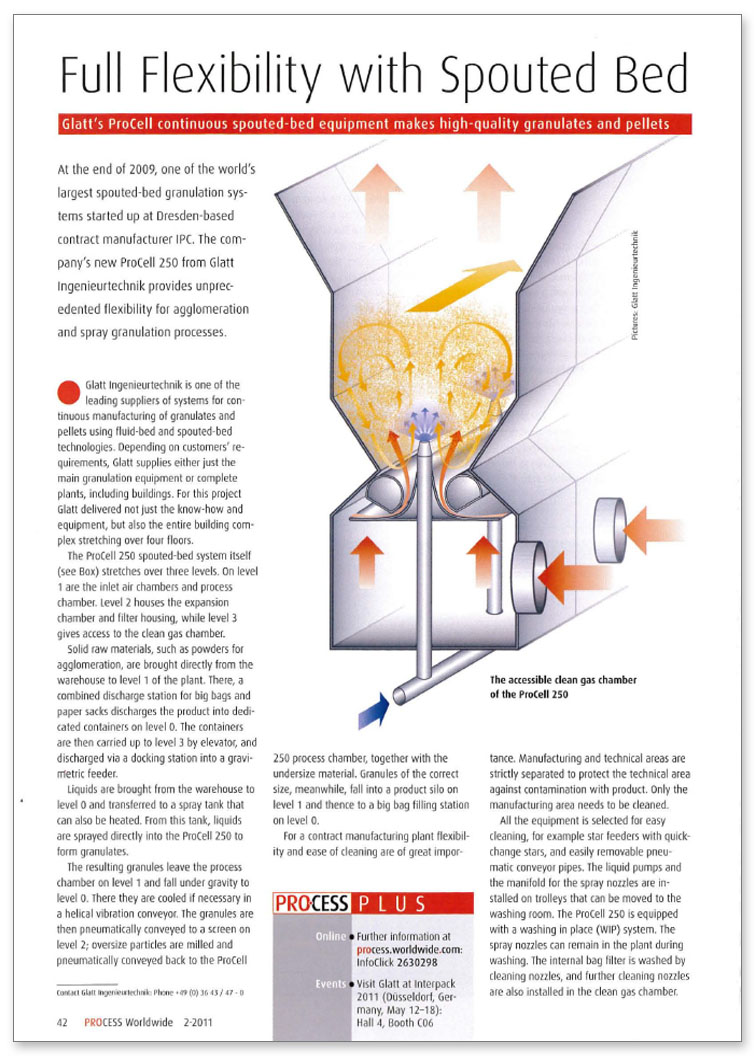

As a process expert for particle design as well as a process and plant engineering service provider, Glatt has been regularly publishing technical papers for several years to provide information on the advantages of Glatt technologies for applications in all bulk solids processing industries. The publications cover topics related to fluid bed and spouted bed technology as well as powder synthesis in pulsating gas flow for the production of innovative high-performance powders and dust-free, easy-flowing granules and pellets with defined properties and functions.