Visualization of the BioCampus MultiPilot (BMP), Copyright: 8quadrat

Glatt Ingenieurtechnik commissioned to plan new BioCampus in Straubing

A flexible platform for the scale-up and commercialization of innovative biotech processes and sustainable products will be created at the Straubing-Sand port in Bavaria, Germany.

Weimar, Germany, March 2022: Glatt Ingenieurtechnik GmbH (Weimar, Germany) will be responsible for the Basic Engineering of the process technology for the multipurpose BioCampus MultiPilot (BMP) plant on behalf of BioCampus Straubing GmbH. Here, at the Straubing-Sand port, customers will be able to develop, test, optimize and scale-up industrial biotechnology processes, validate their economic viability and manufacture samples.

Glatt Ingenieurtechnik will plan the process technology systems, including media supply, process control and automation, as well as the safety technology. To integrate the plant technology into the building concept, Glatt will work closely with the building planning consortium commissioned by BioCampus Straubing GmbH. In the course of Basic Engineering, cross-trade 3D CAD planning, coordination and powerful techniques from Building Information Modeling (BIM) will be used from the very beginning.

Zweckverband Hafen Straubing-Sand initiated and is responsible for the BMP project. Once the planning has been implemented, BioCampus Straubing GmbH will operate the facilities and act as partner for industrial customers.

A sustainable program

The technological focus of the BMP is the application of lignocellulosic raw materials, biochemical product conversion (up to a scale of 25 cubic meters) and the flexible adaptation of processing technology. The use of renewable raw materials for feedstocks in the chemical industry is becoming increasingly important — to achieve climate targets and reduce the use of finite fossil resources.

Dr Thomas Luck, Director Business Development, BioCampus Straubing GmbH, explains: “A key goal of BMP is to close the gap between laboratory and industrial-scale implementation. In the course of market research, we predicted the need for a versatile and flexible plant engineering platform to scale-up and demonstrate new biotechnological processes and technologies. This has been confirmed by specific inquiries from potential customers.”

“In close consultation with interested users,” he added, “we have defined a broad range of equipment that will enable future customers to jointly explore innovative paths to new, sustainable products at BMP. With Glatt Ingenieurtechnik, we have a very competent partner that’s familiar with the specific engineering requirements and has relevant expertise in the planning and construction of plant to process natural or renewable raw materials. The practical experience gained from Glatt’s own pilot plant and scale-up projects, as well as the engineering and construction of demonstration plant for various technologies in Germany and abroad, also speaks in Glatt’s favor.”

Diverse range of services

The project will be built on the BioCampus at the port of Straubing-Sand, which is the most efficient freight traffic center in Lower Bavaria and has excellent infrastructure links by ship, rail and road. An investment subsidy from the State Ministry of Economic Affairs, Regional Development and Energy of the Free State of Bavaria is providing significant support for the construction of the BMP. Non-discriminatory access and the highest level of IP protection are guaranteed for international users ranging from start-ups to SMEs, large corporations and research institutions.

In addition to machinery and equipment, customers will also be offered synergistic services. These include process development, mediation from industry, research, law and financing, consulting and pre-testing for companies planning to invest in their own demonstrators; in short, the BMP provides a target-oriented portfolio to drive bioeconomy projects forward.

The construction of the BMP is intended to further strengthen the BioCampus in the port of Straubing-Sand as a beacon for the bio-based economy and, as a synergetic complement to the facilities of the Competence Center for Renewable Resources (KoNaRo), which is also located in Straubing. Together, they will make a significant contribution to the use of raw materials and help to further establish the Bavarian bioeconomy.

About Zweckverband Hafen Straubing-Sand / BioCampus Straubing GmbH:

Zweckverband Hafen Straubing-Sand (ZVH) operates and develops the port of Straubing-Sand as part of an inter-municipal cooperation between the city of Straubing, the district of Straubing-Bogen and the municipality of Aiterhofen. As a trimodal industrial and logistics site with a total area of 220 hectares, the port of Straubing is Lower Bavaria’s most powerful freight traffic center. The location receives additional attention due to its focus on the bio-based economy. The ZVH subsidiary BioCampus Straubing GmbH (BCG) is working to raise the profile of the Straubing-Bogen region as a business and technology location for the biobased economy and industrial biotechnology. With instruments of business promotion and innovation transfer, start-ups, new settlements and growth of existing companies in the Straubing region are supported, which deal with the utilization of biogenic raw and residual materials. BCG’s work focuses on innovation support services for start-ups within the framework of the start-up competition “PlanB – Biobased.Business.Bavaria.”, the establishment and operation of relevant infrastructures such as the BioCampus MultiPilot demonstration plant and the Technology and Start-up Center in the port in cooperation with the ZVH, as well as networking in the Straubing ecosystem for biobased business.

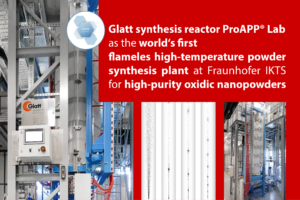

Copyright: Glatt

Copyright: Glatt Copyright: Glatt

Copyright: Glatt