From Hot Gas Stream to Matt Finish by Glatt Powder Synthesis

Whether it’s rapid prototyping, customisation or personalisation, paint manufacturers can usually only dream of what has long been a reality in other industries. Their ideas are thwarted by minimum purchase quantities, a lack of know-how, expensive machinery or the unavailability of yet-to-be-developed powder types. Thanks to a novel method of spray calcination, test-ready additives for rapid market entry can be ready in just a few weeks.

- originally published in: European Coatings Journal, issue November 2018, pages 30–35 (Vincentz Network GmbH & Co. KG)

Companies searching for a novel powder matting agent usually look for more experienced development partners. The Austrian specialty chemicals manufacturer, Pigmentsolution, is one such company and relies on APPtec® for the on-demand development of customer-specific formulations. APPtec® is the innovative pulsating hot gas flow spray-calcination process created by Thuringia-based plant manufacturer Glatt Ingenieurtechnik. In a hot gas reactor, silica (SiO2) is thermally treated in such a way that the surface of the particles is “hardly loaded” and, at the same time, provides the desired added value – such as haze-free transparency, a stimulating wood coating effect, special resistance or an optimal float-and-flow behaviour. This example shows how both large and small businesses can benefit from technologies that bring on-demand paint development solutions within reach.

THE HEYDAY OF DULLNESS

Until a few years ago, gloss was considered to be the ultimate surface finish. Since 2008, however, varnish effects are expected to be satin-finished, scratch-resistant and flawless. It’s that certain something that highlights the streamlined silhouette of sports cars and gives furniture and other products a soft look and touchable quality. Matting agents are usually responsible for that luxurious visual and haptic appeal but, today, they have to do a lot more. These additives are increasingly proving to be a problem solver for a whole range of challenges: they improve the quality of the varnish, make it easier to work with, increase the surface resistance, facilitate cleaning and even – thanks to a flame-retarding component – help to extinguish fires. To deliver these effects, matting agents must have properties that elicit the functionalities of their raw materials – either as a result of a suitable treatment or special particle design.

HOW MATTING ARISES

Matting agents generally consist of precipitated or pyrogenic silicas, silica gels, wax additives and fillers. Until the middle of the 20th century, varnishes were subsequently sanded post-application using pumice powder or steel wool [1]. After the Second World War, because they could be cost-effectively used as additives in coating systems to produce colorful consumer goods, the large-scale production of synthetic silicic acids prevailed.

Modern silica-based matting agents and fillers create the effect of solids protruding from the surface, which form a microstructure during drying. The protruding particles make the surface rougher and diffuse the reflected light. Dull matt lacquered wood, for example, looks unpainted, an optical illusion that has been used by the furniture and flooring industry with foamed backing materials for years [2].

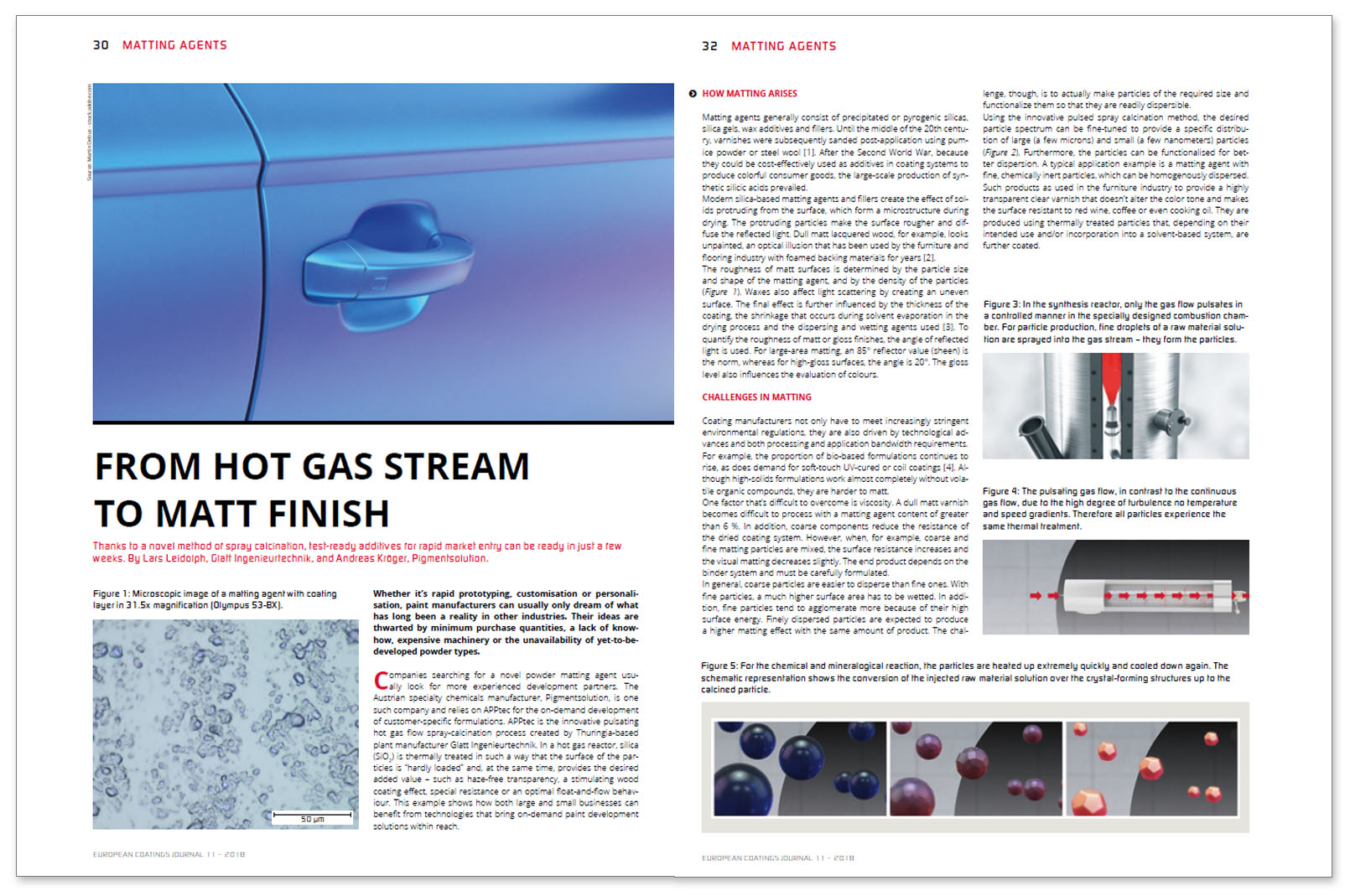

The roughness of matt surfaces is determined by the particle size and shape of the matting agent, and by the density of the particles (Figure 1). Waxes also affect light scattering by creating an uneven surface. The final effect is further influenced by the thickness of the coating, the shrinkage that occurs during solvent evaporation in the drying process and the dispersing and wetting agents used [3]. To quantify the roughness of matt or gloss finishes, the angle of reflected light is used. For large-area matting, an 85° reflector value (sheen) is the norm, whereas for high-gloss surfaces, the angle is 20°. The gloss level also influences the evaluation of colours.

CHALLENGES IN MATTING

Coating manufacturers not only have to meet increasingly stringent environmental regulations, they are also driven by technological advances and both processing and application bandwidth requirements. For example, the proportion of bio-based formulations continues to rise, as does demand for soft-touch UV-cured or coil coatings [4]. Although high-solids formulations work almost completely without volatile organic compounds, they are harder to matt.

One factor that’s difficult to overcome is viscosity. A dull matt varnish becomes difficult to process with a matting agent content of greater than 6 %. In addition, coarse components reduce the resistance of the dried coating system. However, when, for example, coarse and fine matting particles are mixed, the surface resistance increases and the visual matting decreases slightly. The end product depends on the binder system and must be carefully formulated.

In general, coarse particles are easier to disperse than fine ones. With fine particles, a much higher surface area has to be wetted. In addition, fine particles tend to agglomerate more because of their high surface energy. Finely dispersed particles are expected to produce a higher matting effect with the same amount of product. The challenge, though, is to actually make particles of the required size and functionalize them so that they are readily dispersible.

Using the innovative pulsed spray calcination method, the desired particle spectrum can be fine-tuned to provide a specific distribution of large (a few microns) and small (a few nanometers) particles (Figure 2). Furthermore, the particles can be functionalised for better dispersion. A typical application example is a matting agent with fine, chemically inert particles, which can be homogenously dispersed. Such products as used in the furniture industry to provide a highly transparent clear varnish that doesn’t alter the color tone and makes the surface resistant to red wine, coffee or even cooking oil. They are produced using thermally treated particles that, depending on their intended use and/or incorporation into a solvent-based system, are further coated.

PARTICLES FROM THE PULSATING HOT GAS STREAM

The novel Advanced Pulse Powder technology (APPtec®) process builds on established spray calcination technology, wherein calcination refers to altering the chemical composition of a substance by thermally expelling any volatile components. At the heart of the technology is the combustion chamber in the synthesis reactor, in which the pulsating hot gas flow is generated (Figures 3, 4). Solutions, suspensions and solids are thermally treated in a pulsating hot gas stream in a continuous process and transformed into high quality, high performance powders. The particle properties derive from the special combination of process temperature, residence time, frequency and amplitude.

Different process steps such as drying, calcining, particle formation or coating can be combined in a single step. This is possible because the pulsation increases the heat transfer from the gas to the particle by a factor of five to ten compared with a continuous laminar flow. Heating from zero to a process temperature of 200-900 °C takes place within seconds. Plus, it takes only fractions of a second until the solvent has evaporated and the particles have been converted (Figure 5). The residence time ranges from 100 ms to 10 s.

COMMERCIALLY AVAILABLE RAW MATERIALS ARE SUFFICIENT

The raw materials needed for this process do not have to be exceptional. Quite the contrary in fact. As such, commercially available precipitated silica (SiO2) can be converted into higher-value powders with specific properties in the reactor. Another benefit of the method is particle coating, which can be used for protection or to improve the incorporation of the particles into the end product matrix.

WHAT HAPPENS IN THE REACTOR?

A closer look at the SiO2 example shows that the thermal treatment in the hot gas reactor triggers two effects. One, it removes any substances – such as OH groups, for example – with which the surface of the SiO2 has already reacted. Two, through targeted process control during calcination , the pores are closed and the surface is reduced and becomes smoother, which helps to functionalise the particle surface.

The gas atmosphere can be adjusted according to the application – oxidising or O2-free. In addition, the particles may be treated with an organic or inorganic coating to prevent, for example, sedimentation and (re)agglomeration during storage. For example, wax is applied at a maximum of 200 °C so that it doesn’t burn. The wax component binds with the coating matrix and fixes the particle within it (Figure 6). Because of the low temperatures in the reactor, sintering does not occur. Hence, the individual particles are subsequently easy to separate and disperse. The particle size can be analysed by laser diffraction, for example (Figure 7).

MARKET OPPORTUNITIES

Although better dispersal behaviour, more intensive matting or a more consistent surface are certainly advantages, the method also offers potential benefits in the form of niche products that did not exist before. In the pigment sector, for example, effect pigments with a particular luster or shimmer, or special pigments with additional properties such as UV protection, luminosity and/or antimicrobial properties are now possible, as are those that reflect infrared light or offer insulating or heat-conducting properties. Moreover, the possibilities of bio-based formulations and their applications are far from exhausted.

Product improvements are usually made by altering the additive, such as by adjusting the particle size or surface properties. Real innovation requires the production of new powder types. This has largely been the domain of large producers because particle design not only requires product development know-how, it also needs process development experience and extensive technical equipment. Collaboration with partners, who have proven expertise in plant engineering, process development and particle design, as well as in the formulation of coating systems, also makes innovations possible for smaller companies.

PRODUCT SAMPLES WITHIN HOURS

The new thermal treatment opens up many possibilities for the customisation of particle properties in an application-specific manner and to produce novel, not currently available, additive systems. Working collaboratively, required product samples can be generated under industrial conditions and recipes or product ideas – from raw material to a usable amount of powder – can be brought to fruition in a short time, so that pilot projects or the marketability of a product can be assessed quickly. If the raw material is not accessible to the customer because of a minimum purchase requirement, procurement can also be arranged.

What makes processing in the hot gas reactor additionally economical is that there is no waste (unless the raw material proves to be completely useless). However, what enters the pulsating hot gas also comes out the other end –100 % without separating, aggregating or forming hotspots. A usable result from product samples ranging from less than one to several kilograms can be achieved in half a working day – and can then be tested in the laboratory for moisture content, conductivity, release curve, particle size and shape, pH and bulk density. Because scale-up is eliminated, production can start immediately after the successful evaluation of practical tests. Contract manufacturing up to the three-digit tonnage range is also an option, so that paint manufacturers can, in principle, be supplied immediately (Figure 8).

LITERATURE

[1] Bieleman J., Lackadditive, Wiley-VCH Verlag, 1998

[2] Kittel H., Spille J., (Hrsg.), Lehrbuch der Lacke und Beschichtungen, Volume 2: Füllstoffe, 2. Aufl., S. Hirzel Verlag, 2003

[3] Lenz P., Göbelt B., Schulte K., Maßgeschneidert für Mattierungsmittel. In: Farbe und Lack 03/2008, S. 35-38

[4] Gagro D., Biobasierte Lacke: Wachstum weltweit. Im Internet veröffentlicht: 27.11.2017, online unter: http://www.farbeundlack.de/Markt-Branche/Unternehmen-und-Maerkte/Biobasierte-Lacke-Wachstum-weltweit (letzter Aufruf 01.12.2017)

Further information on this topic and related topics can also be found in the following publications:

January 2022: Glatt expands technology center with new laboratory plant for powder synthesis

June 2021: Fraunhofer IKTS operates world’s first flameless high-temperature powder synthesis plant

Published article: ‘Ceramic Raw Materials from the Pulsating Hot Gas Stream’ PDF, English

Published article: ‘New Battery Material by Powder Synthesis’ PDF, English

Published article: ‘Technologies à lit fluidisé / Fluid bed and spouted bed technology’ PDF, English/French

Copyright: Johnson-Johnsen Publishing

Copyright: Johnson-Johnsen Publishing