Spray (micro)encapsulation of sensitive substances in matrix form – An overview of essential oil and vitamin case studies

Phytochemicals are increasingly found in many food ingredients, chemical products and agricultural items. Product and process optimization is becoming ever-more important in all of these industries, with a focus on quality, manufacturing efficiency, stability and formulation costs. Various processes can be used to deliver products with a compact structure. During process development, the most suitable procedures and equipment must be selected, considering the specific project conditions. Case studies, as discussed, can help process engineers and product developers to assess plant configurations in an efficient manner to meet a customer’s specific project requirements.

- Author: Dr. Michael Jacob, Head of Process Technology Food, Feed & Fine Chemicals, Glatt Ingenieurtechnik GmbH

- originally published in the trade magazine ‘Innovations in Food Technology’, issue 11/2019

Phytochemicals are increasingly found in many food ingredients, chemical products and agricultural items. Product and process optimization is becoming ever-more important in all of these industries, with a focus on quality, manufacturing efficiency, stability and formulation costs.

Essential oils are volatile substances with a relatively high vapor pressure; they are susceptible to oxidation and light and may change or may even lose their properties when directly exposed to stressors. Like other sensitive, volatile, odor- or taste-intensive liquid active ingredients, they must therefore be protected from the environment or vice versa. For this protection and to simplify handling — as well as for better dosage and targeted release — these substances are therefore progressively offered and used in encapsulated and/or free-flowing forms.

Various processes can be used to deliver products with a compact structure. During process development, the most suitable procedures and equipment must be selected, considering the specific project conditions. Such factors are, for example, the raw material properties, the availability of approved additives for the formulation, the application area of the product and the specification of the product itself. Supplementary regulations, guidelines and functionality are just as important as product and plant safety. In all instances, the project must be specified as comprehensively as possible to evaluate various process designs and options. The inherent considerations of the individual industries, be it pharmaceutical or food, for example, must also be taken into account.

Microencapsulation, based on fluidized bed technology, is the inclusion of an active substance in a solid matrix. Microcapsules provide an ideal vehicle to control and protect vitamins, flavors or polyunsaturated fatty acids (PUFAs), as well as volatile essential oils. Selecting the right matrix materials makes the targeted release of these active substance possible. The matrix material forms the carrier and the active substance is physically embedded in the solidified particle structure.

The basic principle of fluidized bed-based spray granulation involves spraying a liquid onto fluidized particles to wet their entire surface area. By simultaneously drying and hardening the liquid film, the particles increase in size, layer by layer. Compared with other drying-based encapsulation processes, such as conventional spray drying, the particle and bulk properties can be adjusted quite easily. Thus, depending on the properties of the liquid, the particle size and structure, the spraying conditions and the residence time can all be modified. With this process, almost spherical particles can be produced in a size range of 100 µm up to a few millimeters. The mass fraction of the encapsulated component can also be adjusted. Microcapsules produced in this way have a closed surface and a compact structure, resulting in the stable, long-term inclusion of the active substance.

To optimize product performance and process efficiency, both formulation and operating parameters should be considered during process development. This is key for customized properties and is illustrated in the following case studies. All experimental work was done using a laboratory scale unit from Glatt.

The ProCell LabSystem is modular by design and suitable for a wide range of process development and evaluation applications. Various inserts are available for batch and continuous processing, fluidized and spouted bed operation and any kind of liquid spray.

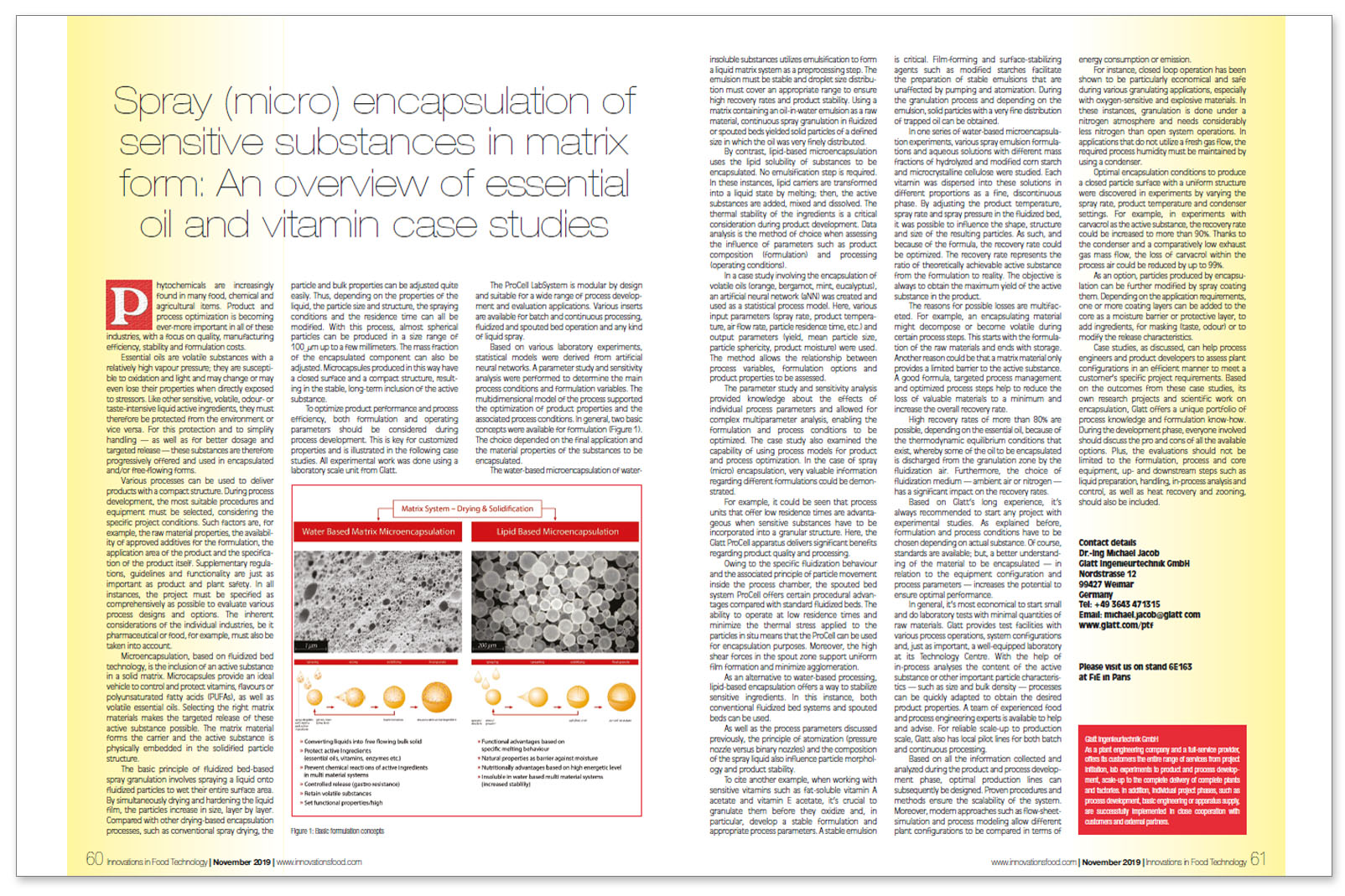

Based on various laboratory experiments, statistical models were derived from artificial neural networks. A parameter study and sensitivity analysis were performed to determine the main process conditions and formulation variables. The multidimensional model of the process supported the optimization of product properties and the associated process conditions. In general, two basic concepts were available for formulation (Figure 1). The choice depended on the final application and the material properties of the substances to be encapsulated.

The water-based microencapsulation of water-insoluble substances utilizes emulsification to form a liquid matrix system as a preprocessing step. The emulsion must be stable and droplet size distribution must cover an appropriate range to ensure high recovery rates and product stability. Using a matrix containing an oil-in-water emulsion as a raw material, continuous spray granulation in fluidized or spouted beds yielded solid particles of a defined size in which the oil was very finely distributed.

By contrast, lipid-based microencapsulation uses the lipid solubility of substances to be encapsulated. No emulsification step is required. In these instances, lipid carriers are transformed into a liquid state by melting; then, the active substances are added, mixed and dissolved. The thermal stability of the ingredients is a critical consideration during product development. Data analysis is the method of choice when assessing the influence of parameters such as product composition (formulation) and processing (operating conditions).

In a case study involving the encapsulation of volatile oils (orange, bergamot, mint, eucalyptus), an artificial neural network (aNN) was created and used as a statistical process model. Here, various input parameters (spray rate, product temperature, air flow rate, particle residence time, etc.) and output parameters (yield, mean particle size, particle sphericity, product moisture) were used. The method allows the relationship between process variables, formulation options and product properties to be assessed.

The parameter study and sensitivity analysis provided knowledge about the effects of individual process parameters and allowed for complex multiparameter analysis, enabling the formulation and process conditions to be optimized. The case study also examined the capability of using process models for product and process optimization. In the case of spray (micro) encapsulation, very valuable information regarding different formulations could be demonstrated.

For example, it could be seen that process units that offer low residence times are advantageous when sensitive substances have to be incorporated into a granular structure. Here, the Glatt ProCell apparatus delivers significant benefits regarding product quality and processing.

Owing to the specific fluidization behavior and the associated principle of particle movement inside the process chamber, the spouted bed system ProCell offers certain procedural advantages compared with standard fluidized beds. The ability to operate at low residence times and minimize the thermal stress applied to the particles in situ means that the ProCell can be used for encapsulation purposes. Moreover, the high shear forces in the spout zone support uniform film formation and minimize agglomeration.

As an alternative to water-based processing, lipid-based encapsulation offers a way to stabilize sensitive ingredients. In this instance, both conventional fluidized bed systems and spouted beds can be used.

As well as the process parameters discussed previously, the principle of atomization (pressure nozzle versus binary nozzles) and the composition of the spray liquid also influence particle morphology and product stability.

To cite another example, when working with sensitive vitamins such as fat-soluble vitamin A acetate and vitamin E acetate, it’s crucial to granulate them before they oxidize and, in particular, develop a stable formulation and appropriate process parameters. A stable emulsion is critical. Film-forming and surface-stabilizing agents such as modified starches facilitate the preparation of stable emulsions that are unaffected by pumping and atomization. During the granulation process and depending on the emulsion, solid particles with a very fine distribution of trapped oil can be obtained.

In one series of water-based microencapsulation experiments, various spray emulsion formulations and aqueous solutions with different mass fractions of hydrolyzed and modified corn starch and microcrystalline cellulose were studied. Each vitamin was dispersed into these solutions in different proportions as a fine, discontinuous phase. By adjusting the product temperature, spray rate and spray pressure in the fluidized bed, it was possible to influence the shape, structure and size of the resulting particles. As such, and because of the formula, the recovery rate could be optimized. The recovery rate represents the ratio of theoretically achievable active substance from the formulation to reality. The objective is always to obtain the maximum yield of the active substance in the product.

The reasons for possible losses are multifaceted. For example, an encapsulating material might decompose or become volatile during certain process steps. This starts with the formulation of the raw materials and ends with storage. Another reason could be that a matrix material only provides a limited barrier to the active substance. A good formula, targeted process management and optimized process steps help to reduce the loss of valuable materials to a minimum and increase the overall recovery rate.

High recovery rates of more than 80% are possible, depending on the essential oil, because of the thermodynamic equilibrium conditions that exist, whereby some of the oil to be encapsulated is discharged from the granulation zone by the fluidization air. Furthermore, the choice of fluidization medium — ambient air or nitrogen — has a significant impact on the recovery rates.

Based on Glatt’s long experience, it’s always recommended to start any project with experimental studies. As explained before, formulation and process conditions have to be chosen depending on actual substance. Of course, standards are available; but, a better understanding of the material to be encapsulated — in relation to the equipment configuration and process parameters — increases the potential to ensure optimal performance.

In general, it’s most economical to start small and do laboratory tests with minimal quantities of raw materials. Glatt provides test facilities with various process operations, system configurations and, just as important, a well-equipped laboratory at its Technology Centre. With the help of in-process analyses the content of the active substance or other important particle characteristics — such as size and bulk density — processes can be quickly adapted to obtain the desired product properties. A team of experienced food and process engineering experts is available to help and advise. For reliable scale-up to production scale, Glatt also has local pilot lines for both batch and continuous processing.

Based on all the information collected and analyzed during the product and process development phase, optimal production lines can subsequently be designed. Proven procedures and methods ensure the scalability of the system. Moreover, modern approaches such as flow-sheet-simulation and process modeling allow different plant configurations to be compared in terms of energy consumption or emission.

For instance, closed loop operation has been shown to be particularly economical and safe during various granulating applications, especially with oxygen-sensitive and explosive materials. In these instances, granulation is done under a nitrogen atmosphere and needs considerably less nitrogen than open system operations. In applications that do not utilize a fresh gas flow, the required process humidity must be maintained by using a condenser.

Optimal encapsulation conditions to produce a closed particle surface with a uniform structure were discovered in experiments by varying the spray rate, product temperature and condenser settings. For example, in experiments with carvacrol as the active substance, the recovery rate could be increased to more than 90%. Thanks to the condenser and a comparatively low exhaust gas mass flow, the loss of carvacrol within the process air could be reduced by up to 99%.

As an option, particles produced by encapsulation can be further modified by spray coating them. Depending on the application requirements, one or more coating layers can be added to the core as a moisture barrier or protective layer, to add ingredients, for masking (taste, odor) or to modify the release characteristics.

Case studies, as discussed, can help process engineers and product developers to assess plant configurations in an efficient manner to meet a customer’s specific project requirements. Based on the outcomes from these case studies, its own research projects and scientific work on encapsulation, Glatt offers a unique portfolio of process knowledge and formulation know-how. During the development phase, everyone involved should discuss the pro and cons of all the available options. Plus, the evaluations should not be limited to the formulation, process and core equipment, up- and downstream steps such as liquid preparation, handling, in-process analysis and control, as well as heat recovery and zooning, should also be included.

Glatt Ingenieurtechnik GmbH Weimar, as a plant engineering company and a full-service provider, offers its customers the entire range of services from project initiation, lab experiments to product and process development, scale-up to the complete delivery of complete plants and factories. In addition, individual project phases, such as process development, basic engineering or apparatus supply, are successfully implemented in close cooperation with customers and external partners.

Further information on this topic and related topics can also be found in the following publications:

Published article: ‘How to Tame Recalcitrant Ingredients with Technological Processes’ PDF, English

Published article: ‘The gentle processing of highly volatile oils by fluid bed and spouted bed technology’ PDF, English

Published article: ‘Fluid bed and spouted bed technologies – Optimising functional ingredients for enhanced nutrition’ PDF, English

Published article: ‘Hot-melt applications for the food and beverage industry – How to safely stabilize vitamins and probiotics’ PDF, English

Published article: ‘Spray agglomerating plant-based milk alternatives for optimised product properties’ PDF, English

Copyright: LT Food Medien-Verlag GmbH

Copyright: LT Food Medien-Verlag GmbH Copyright: EC PRESSE

Copyright: EC PRESSE