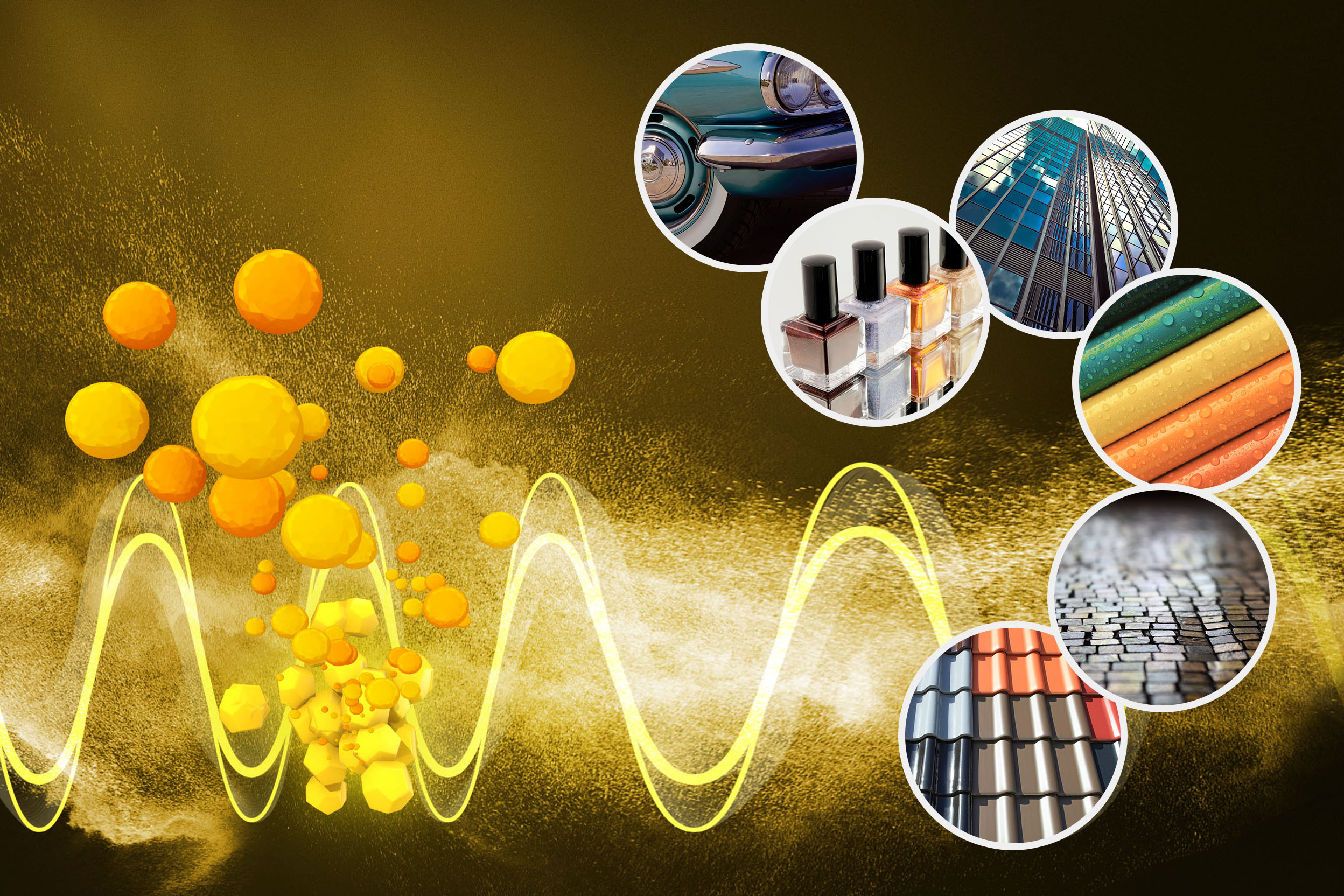

Adjust matting properties. Create innovative pigment effects. Improve dispersibility.

Paint pigments, color pigments and effect pigments are conquering new industries and applications. Today, those who want to stand out from the mass market will find many options for innovative products. In addition to effect pigments for more color strength and color variety, there are special pigments with gloss and shimmer effects. Paint and varnish pigments with novel additional properties – such as UV protection, luminescent effects or self-cleaning or antimicrobial action – are also gaining ground. Other examples of properties of effect pigments are the reflection of infrared light and insulating or heat-conducting properties.

Paint and coatings manufacturers have to comply with increasingly stringent environmental regulations. At the same time, processing requirements and the range of applications are increasing. One trend, therefore, is toward the use of ever finer pigments that produce a stronger effect with the same amount of product. The key to this lies in a more homogeneous distribution of the particles within the ink or coating layer. The challenge in using very fine particles is their dispersibility due to their high specific surface area and associated strong tendency to agglomerate.

Discover the process possibilities of Glatt powder synthesis to specifically adjust product properties such as particle size, morphology and surface texture. Based on conventional, commercially available raw materials, this technology can also be used to refine very fine particles in the nano and micrometer range and adapt them to the specific task.

Within the synthesis reactor, the starting material interacts in the pulsating hot gas flow and achieves different effects: Unwanted deposits on the surface are removed. The porosity of the surface can be modified. It is also possible to coat the particles with an organic or inorganic coating. The key to product success lies in optimal process control as well as in the selection of suitable raw materials.

Together with Glatt, your formulations and product ideas can be brought from raw material to production in a short time.

At the Glatt Technology Center in Weimar, we work with you to determine the optimum process conditions for your product in feasibility trials for product development. Various laboratory facilities and comprehensive analytical equipment are available for this purpose. On our pilot plants, we optimize the process and scale it up reliably to a stable and economical production scale. The results from this form the basis for the design and construction as well as the erection of your plant, tailored to your requirements. As an alternative to our own process technology, we offer you the outsourcing of your production by means of contract manufacturing at Glatt.

You don’t have to limit yourself to commercial products. Develop your powder to fit your requirements exactly!

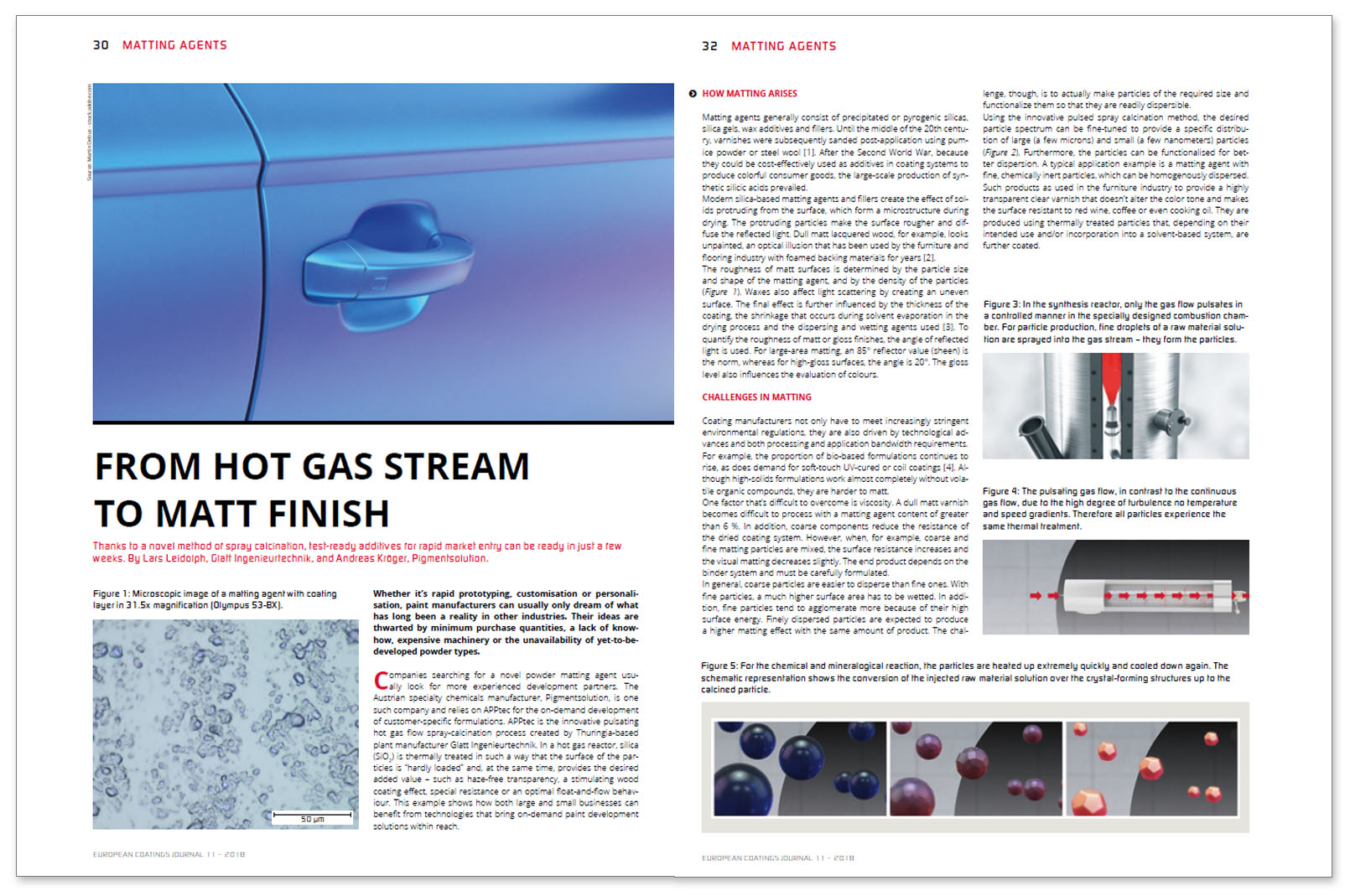

Published article: From Hot Gas Stream to Matt Finish by Glatt Powder Synthesis

Whether it’s rapid prototyping, customisation or personalisation, paint manufacturers can usually only dream of what has long been a reality in other industries. Their ideas are thwarted by minimum purchase quantities, a lack of know-how, expensive machinery or the unavailability of yet-to-be-developed powder types. Thanks to a novel method of spray calcination, test-ready additives for rapid market entry can be ready in just a few weeks.

» originally publishe in the magazine European Coatings Journal, issue November 2018, pages 30–35 (Vincentz Network GmbH & Co. KG)

Further information on applications of Glatt powder synthesis can also be found in the following publications:

March 2022: Glatt expands technology center with new laboratory plant for powder synthesis

March 2021: Glatt Ingenieurtechnik celebrates continued business success with third expansion of its Technology Center

Published article: ‘New Battery Material by Powder Synthesis’ PDF, English

Published article: ‘Coated zirconia for medical technology by specialized powder synthesis’ PDF, German

Published article: ‘Glatt Powder Synthesis – Pioneering Process for Groundbreaking Particle Synthesis’ PDF, English