Improve sintering properties. Increase strength. Increase catalytic effect.

Are you reaching the technological limits of the ceramic raw materials you use in terms of quality and performance? Would you like to increase their strength, improve their sintering properties or increase their catalytic effect? The solution is tailor-made adjustments to the composition of the raw materials. Design your raw materials according to your requirements and determine the future product properties in a targeted manner!

Glatt powder synthesis is an effective tool for the development and industrial production of high-quality ceramic materials. The high flexibility of this technology and the special conditions in the pulsating hot gas stream allow the production and refinement of innovative ceramic powders.

The use of dissolved starting raw materials makes it possible to distribute even the smallest amounts of doping elements homogeneously in the end product. The powders in the nano to single-digit micrometer range already exhibit high sintering activity due to their high specific surface area. This is reinforced by the crystallographic composition in the material. Due to the very fast drying of the material and the quenching at the end of the reactor tube, disequilibrium states can be frozen. This leads to a high diffusivity during the downstream sintering process.

Improved sintering can also be achieved by coating the raw materials. With an appropriate selection of raw materials, the diffusion readiness of the surface layers can be increased, or the melting temperature can be lowered locally.

We will be pleased to support you in the realization of your product innovations. At the Glatt Technology Center in Weimar, we work with you to determine the optimum process conditions for your product in feasibility trials for product development. Various laboratory facilities and comprehensive analytical equipment are available for this purpose. On our pilot plants, we optimize the process and scale it up reliably to a stable and economical production scale. The results from this form the basis for the design and construction as well as the erection of your plant, tailored to your requirements. As an alternative to our own process technology, we offer you the outsourcing of your production by means of contract manufacturing at Glatt.

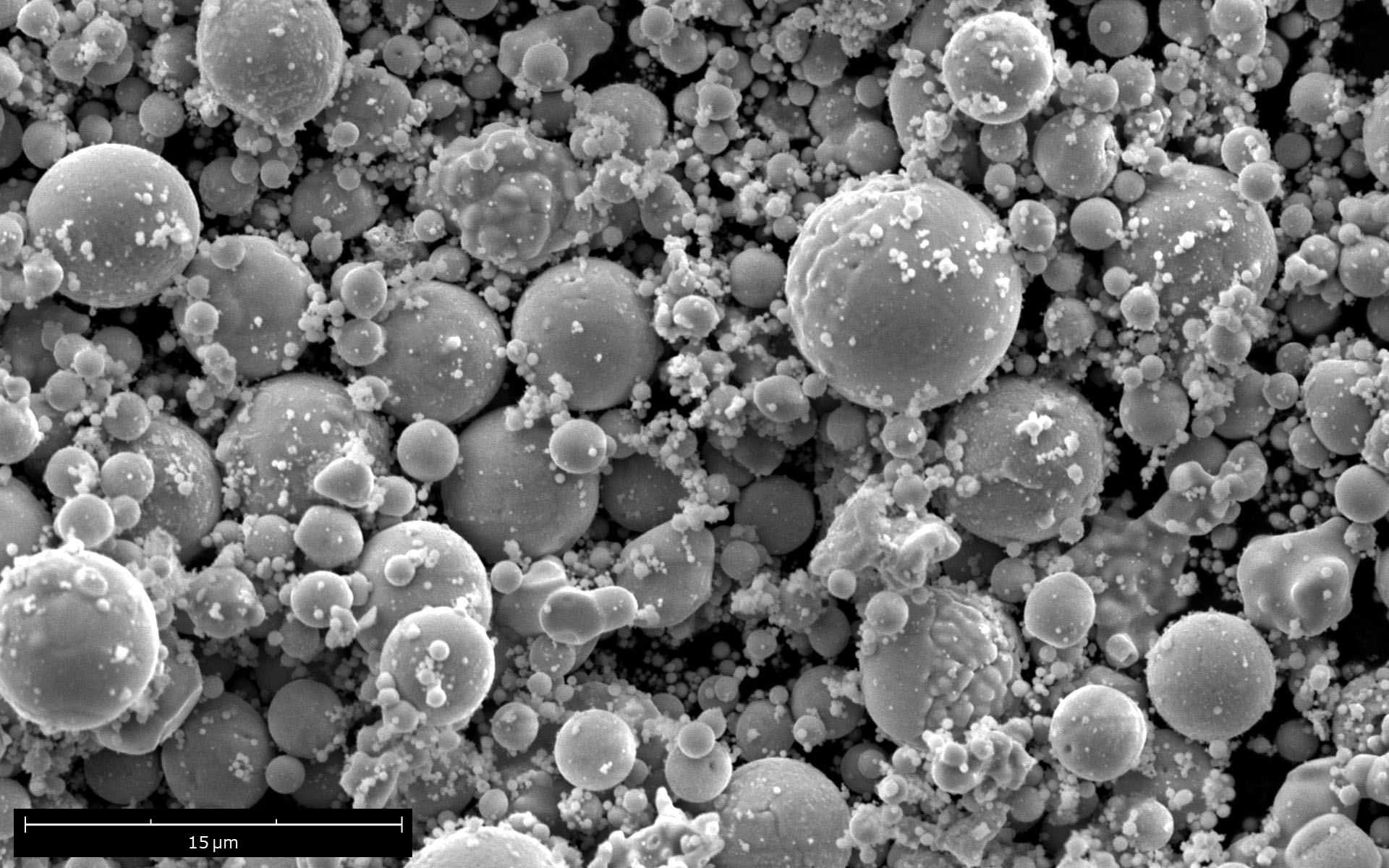

Synthesized BSCF powder, catalytically active oxide ceramics, REM

Case study: oxygen membranes

The objective was to develop a technology for the mass production of the material BSCF (Ba0,5Sr0,5Co0,8Fe0,2O3-x), for the production of membranes for oxygen separation, at low cost. Glatt powder synthesis was used to influence the particle morphology by varying the various variables influencing the process, thus optimizing the raw materials for subsequent processing into membrane components.

Zirconium oxide ZrO2, coated with yttrium oxide Y2O3, core-shell coating, REM

Case study: Coated zirconia

It is known from the literature that yttria-coated zirconia can be sintered at lower temperatures than homogeneously doped material. At the same time, mechanical properties improve after the sintering process. Against this background, the aim was to produce a process for the industrial manufacture of yttria-coated zirconia.

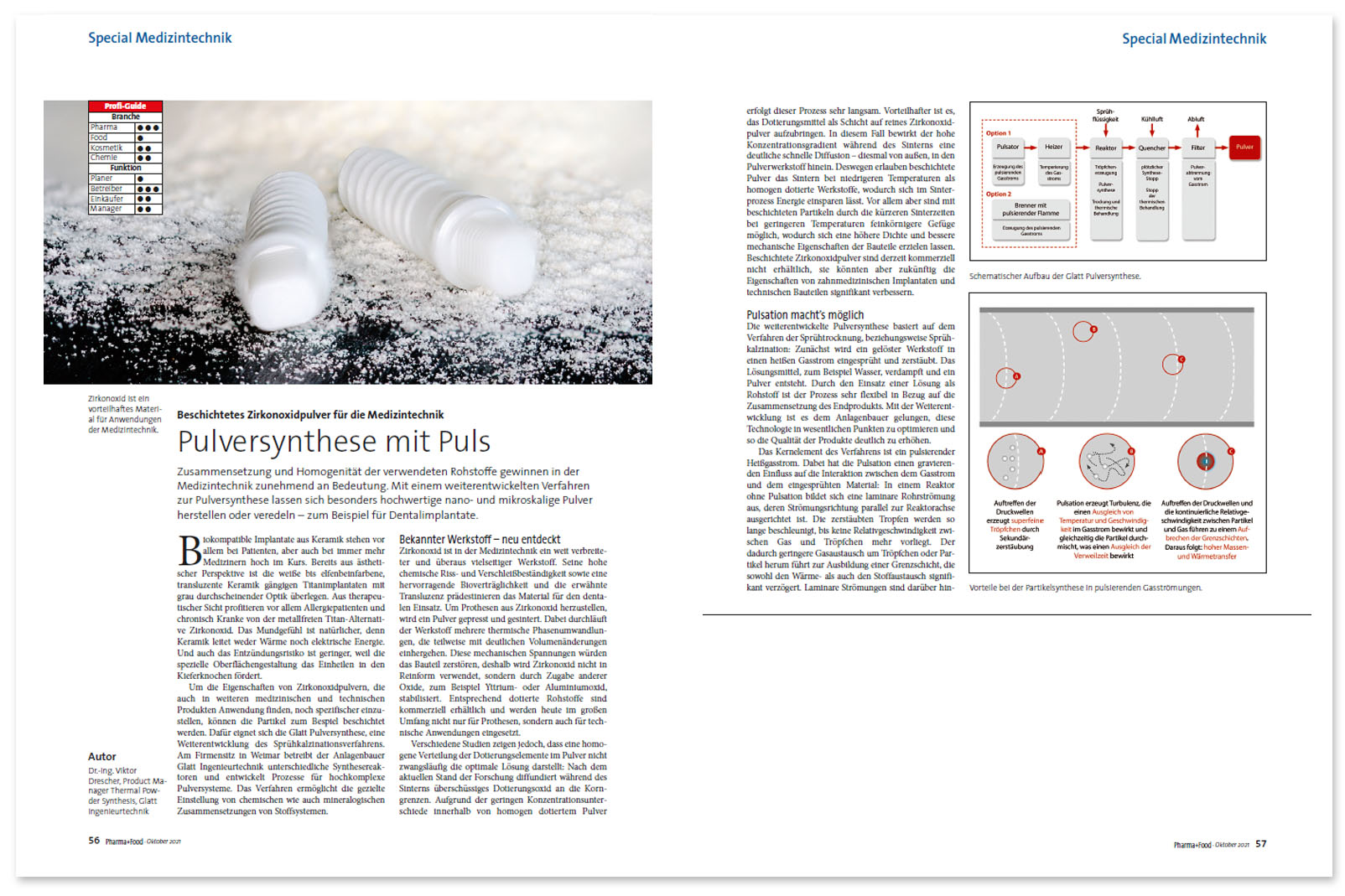

Published article: Coated zirconia for medical technology by specialized powder synthesis (German article)

The composition and homogeneity of the raw materials used are becoming increasingly important in medical technology. With an advanced powder synthesis process, particularly high-quality nano- and microscale powders can be produced or refined – for example, for dental implants.

To make the properties of zirconium oxide powders, which are also used in other medical and technical products, even more specific, the particles can be coated, for example. Glatt powder synthesis, a further development of the spray calcination process, is suitable for this purpose. At its headquarters in Weimar, the plant manufacturer Glatt Ingenieurtechnik operates various synthesis reactors and develops processes for highly complex powder systems. The process enables the targeted adjustment of chemical as well as mineralogical compositions of material systems. (Article in German language)

» Author: Dr.-Ing. Viktor Drescher, Product Manager Thermal Powder Synthesis, Glatt Ingenieurtechnik GmbH

» originally published in the magazine ‘Pharma+Food’, issue 7/2021, Hüthig GmbH

Further information on applications of Glatt powder synthesis can also be found in the following publications:

March 2022: Glatt expands technology center with new laboratory plant for powder synthesis

June 2021: Fraunhofer IKTS operates world’s first flameless high-temperature powder synthesis plant

Published article: ‘New Battery Material by Powder Synthesis’ PDF, English

Published article: ‘Glatt Powder Synthesis – Pioneering Process for Groundbreaking Particle Synthesis’ PDF, English

Published article: ‘From Hot Gas Stream to Matt Finish by Glatt Powder Synthesis’ PDF, English