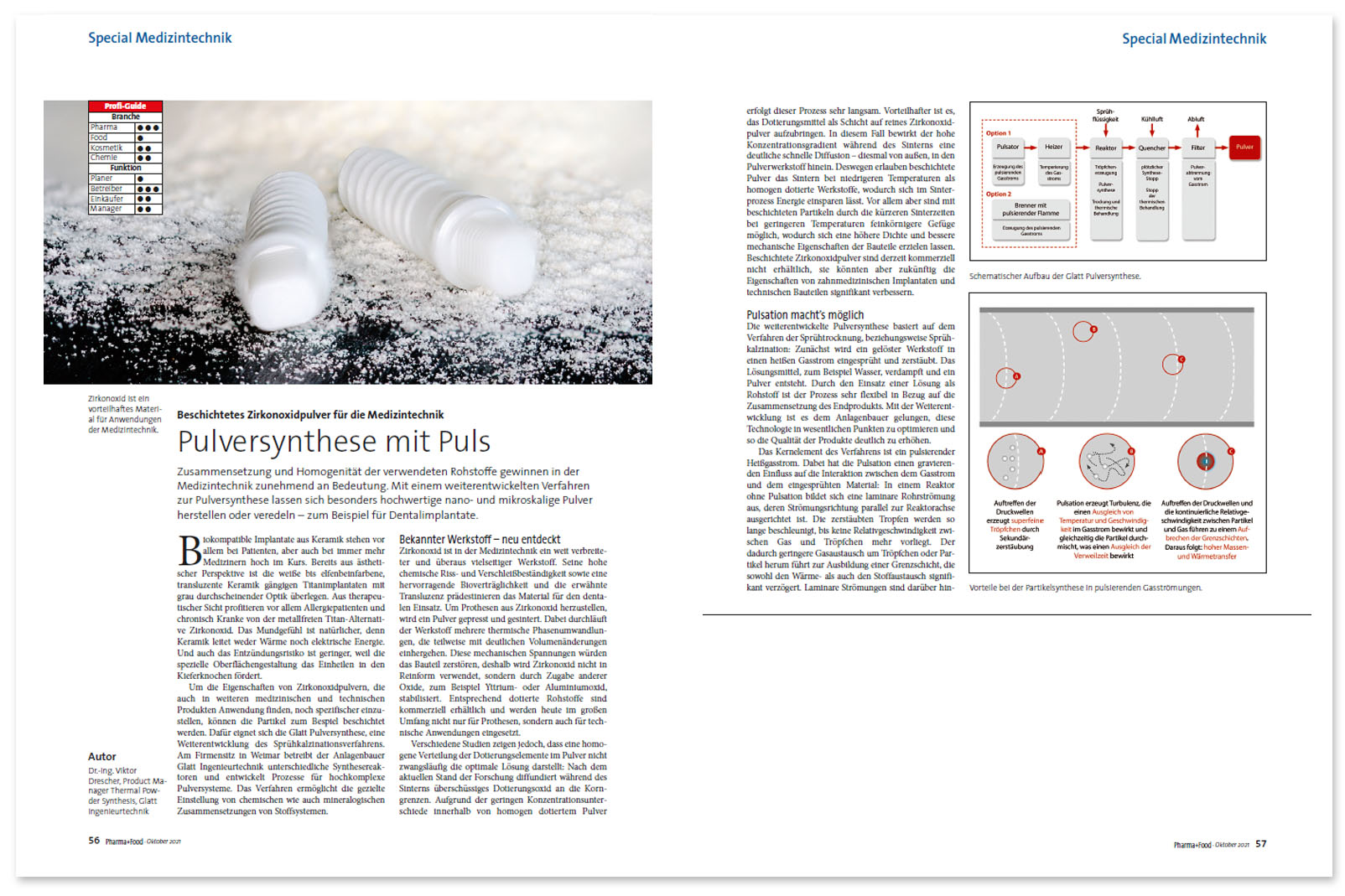

Coated zirconia for medical technology by specialized powder synthesis (German article)

The composition and homogeneity of the raw materials used are becoming increasingly important in medical technology. With an advanced powder synthesis process, particularly high-quality nano- and microscale powders can be produced or refined – for example, for dental implants.

To make the properties of zirconium oxide powders, which are also used in other medical and technical products, even more specific, the particles can be coated, for example. Glatt powder synthesis, a further development of the spray calcination process, is suitable for this purpose. At its headquarters in Weimar, the plant manufacturer Glatt Ingenieurtechnik operates various synthesis reactors and develops processes for highly complex powder systems. The process enables the targeted adjustment of chemical as well as mineralogical compositions of material systems. (Article in German language)

- Author: Dr.-Ing. Viktor Drescher, Product Manager Thermal Powder Synthesis, Glatt Ingenieurtechnik GmbH

- originally published in the magazine ‘Pharma+Food’, issue 7/2021, Hüthig GmbH

- Beschichtetes Zirkonoxidpulver für die Medizintechnik (pharma-food.de)

Further information on this topic and related topics can also be found in the following publications:

Glatt Technical Paper: ‘Ceramic Raw Materials from the Pulsating Hot Gas Stream’ PDF, English

June 2021: Fraunhofer IKTS operates world’s first flameless high-temperature powder synthesis plant

March 2022: Glatt expands technology center with new laboratory plant for powder synthesis

Published article: ‘New Battery Material by Powder Synthesis’ PDF, English

Glatt Technical Paper: ‘Glatt Powder Synthesis – Pioneering Process for Groundbreaking Particle Synthesis’. PDF, English

Copyright: HPCi Media Limited

Copyright: HPCi Media Limited Copyright: Glatt

Copyright: Glatt