Designing customized anode and cathode materials and solid electrolytes by Glatt powder synthesis

Do you want to advance battery technology with innovative processes and improved raw materials? Commercial raw materials do not meet your expectations in terms of capacity and long-term stability? Or do you have a promising material approach that only works on a laboratory scale?

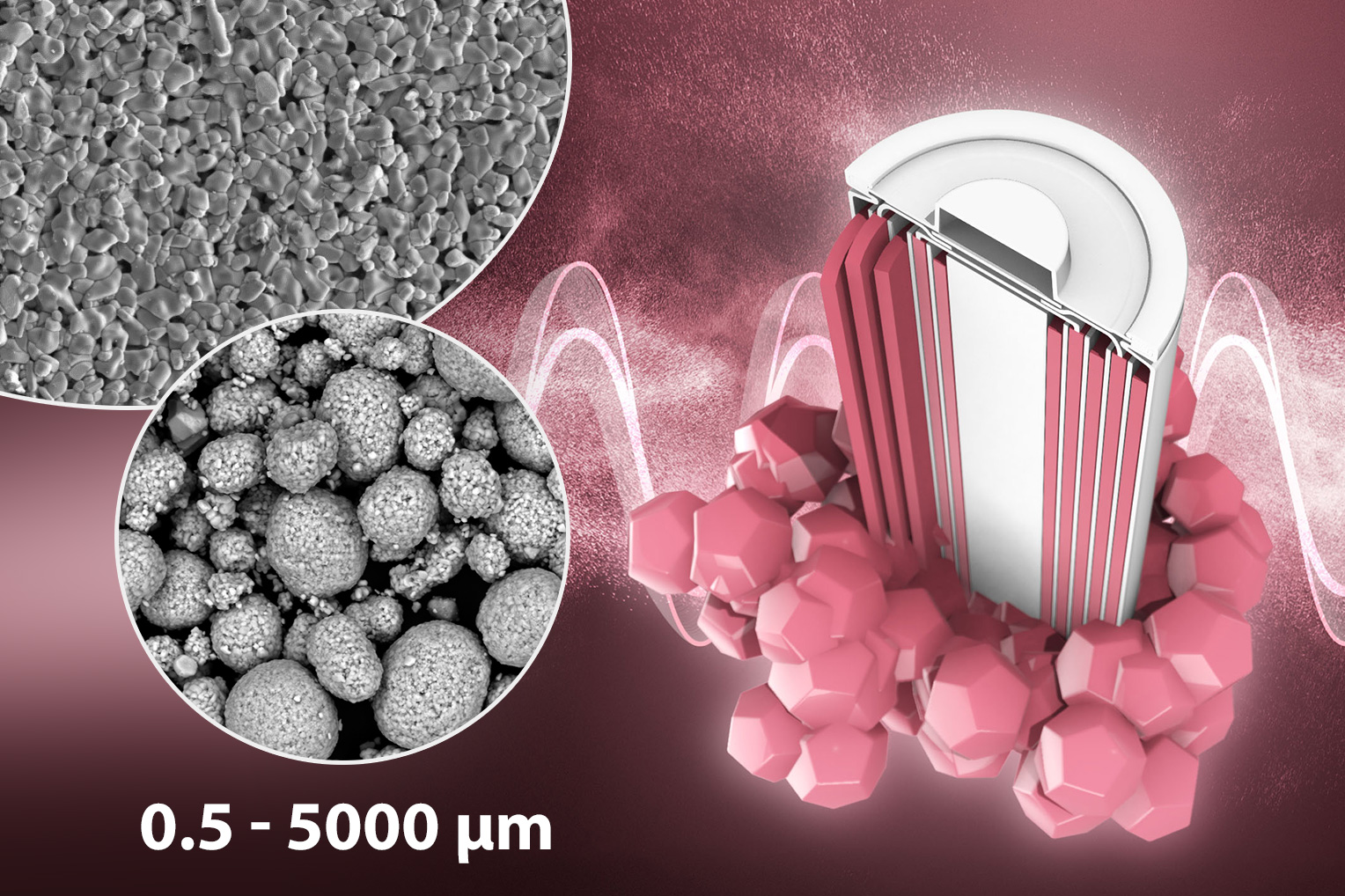

Glatt powder synthesis is a versatile tool for the development and industrial production of innovative battery materials.

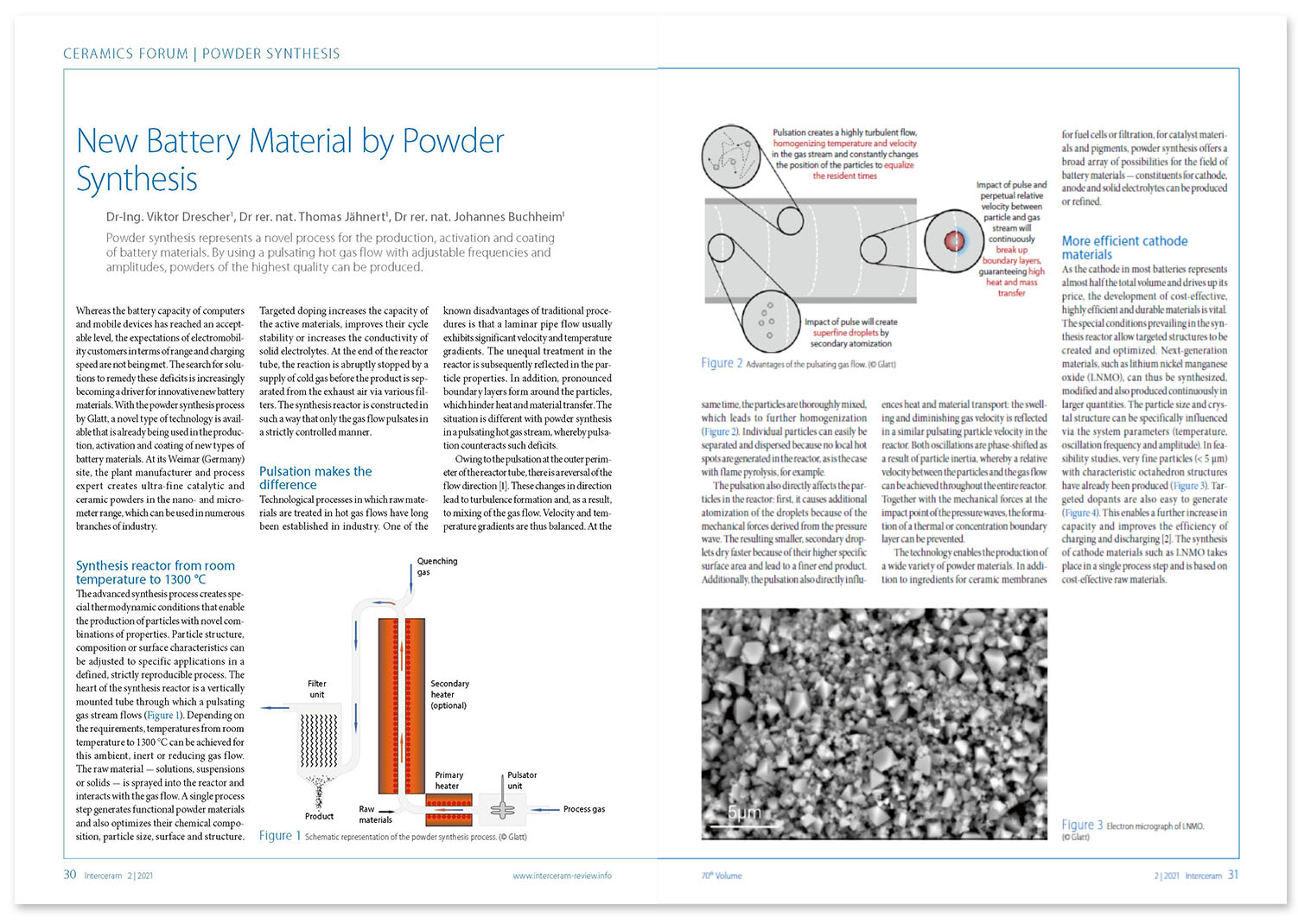

The high flexibility of this technology and the special conditions in the pulsating hot gas stream let you produce active materials and solid electrolytes in just a few process steps.

To produce a homogeneous powder e.g., a cathode material or solid electrolyte, a mixture of the raw materials in the desired stoichiometry – typically a solution – is used and dried in the pulsating hot gas stream. This approach allows the addition of doping elements to stabilize characteristic material properties of the final product to improve its performance. Hereby, features such as capacity and charging behavior of modern battery materials can be influenced in a quality-enhancing manner.

The performance of an active material depends not only on the characteristic material properties but also on the interactions and side reactions with the electrolyte. By coating, the surface of anode and cathode materials can be protected against unwanted side reactions. To apply such a core-shell coating, the material that will form the shell is dissolved in a suspension of a solvent and the solid core material, sprayed and dried. Process temperatures in the range between room temperature and 1300 °C offer an almost inexhaustible choice of core-shell combinations.

Refining battery raw materials by Glatt fluid bed technology

Do you have issues with the homogeneity of your battery raw materials? Is the processability of materials you are using right now constrained by segregation, dust formation or poor pourability?

To improve the processability of powder mixtures, spray agglomeration in the fluid bed can counteract segregation in subsequent processes, packaging or transport. By spraying on a binder solution, the surface of the mixture is wetted and fine particles agglomerate into larger granules. In case of a wide or undefined particle size distribution, fine particles can alternatively be sprayed on together with the binder solution and thus be homogeneously distributed over the coarser components. Homogeneity and pourability of your raw materials will be improved, dust formation prevented.

Fluid bed technology does offer additional options that will help you to optimize your raw materials or their precursors to create exactly the material, you need for your application. Based on the system specification and process parameters you can use the same technology either for spray drying or to bring a functional or protective layer on your powder material. Spray granulation can be used to create pourable, compact, and stable precursor granules out of suspensions. These granules can be later heat treated, or processed in a high temperature fluid bed system, utilizing its higher heat and mass transfer rates.

Develop and test your material in the Glatt Technology Center in Weimar

At the Glatt Technology Center in Weimar, we work with you to determine the optimum process conditions for your product in feasibility trials for product development. Various laboratory facilities and comprehensive analytical equipment are available for this purpose. On our pilot plants, we optimize the process and scale it up reliably to a stable and economical production scale. The results from this form the basis for the design and construction as well as the erection of your fluid bed or spouted bed plant, tailored to your requirements. As an alternative to our own process technology, we offer you the outsourcing of your production by means of contract manufacturing at Glatt.

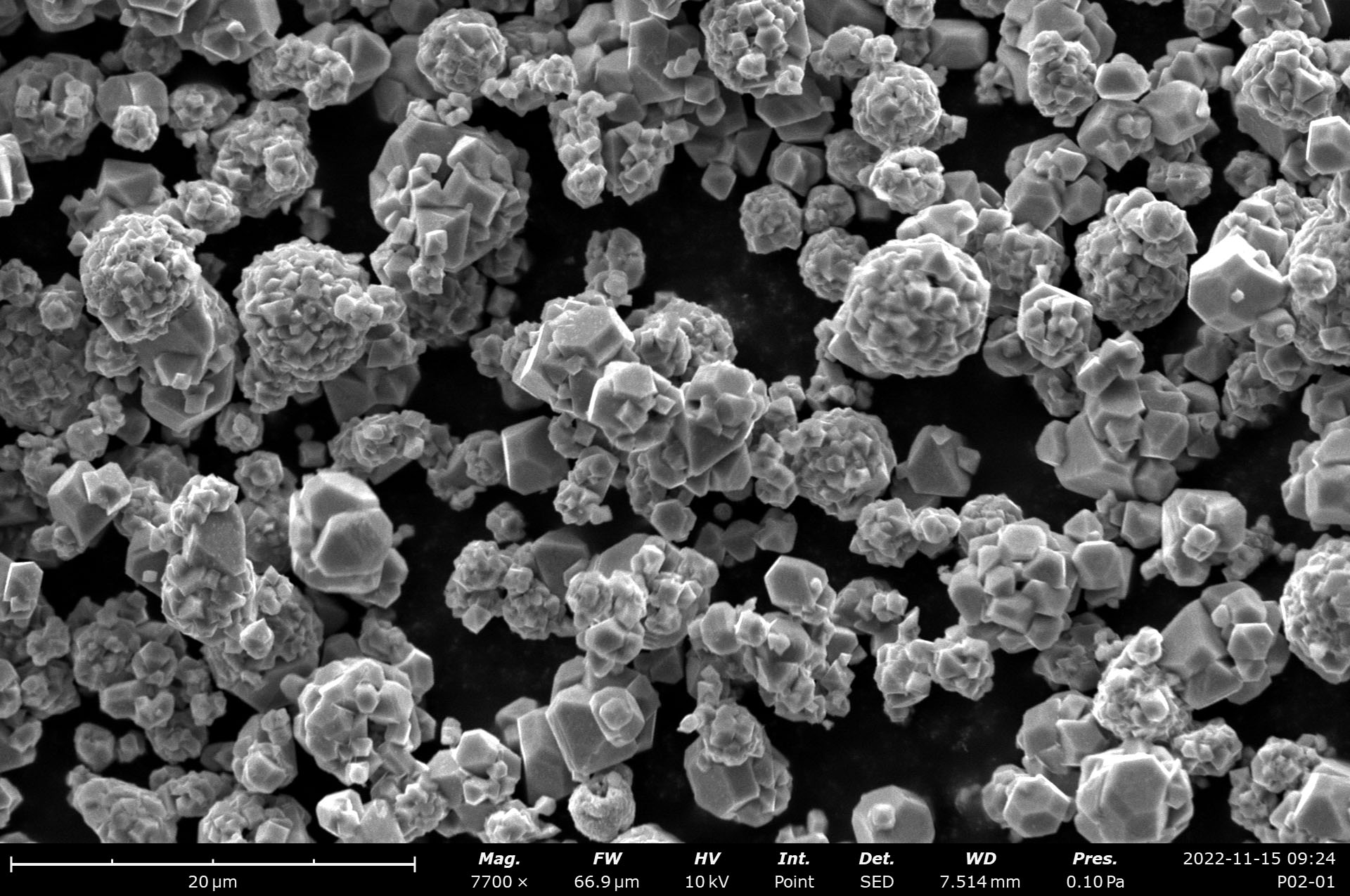

LMNO cathode material produced by Glatt powder synthesis

Case study: Cathode material

The cathode takes up almost half of the battery’s material expenses and drives up its price. Therefore, the development of cost-effective, highly efficient, and durable materials is of utmost importance.

The way to a cost-efficient mass production of lithium nickel manganese oxide (LNMO) leads to Glatt powder synthesis. Due to the special conditions prevailing in the synthesis reactor, targeted particle morphologies and characteristics can be generated and optimized. Next generation materials can be synthesized, modified, and produced continuously in larger quantities using this technology.

The particle size surface properties and crystallinity can be specifically influenced by the plant parameters temperature, vibration frequency and amplitude. In feasibility studies, very fine particles (smaller than 5 µm) with the characteristic structure have already been generated. Targeted dopants can also be realized easily. These enable a further increase in capacity and improve efficiency for fast charging and discharging. The synthesis of cathode materials is carried out in one process step and is based on inexpensive raw materials. This makes up-scaling and thus future large-scale use possible in the first place.

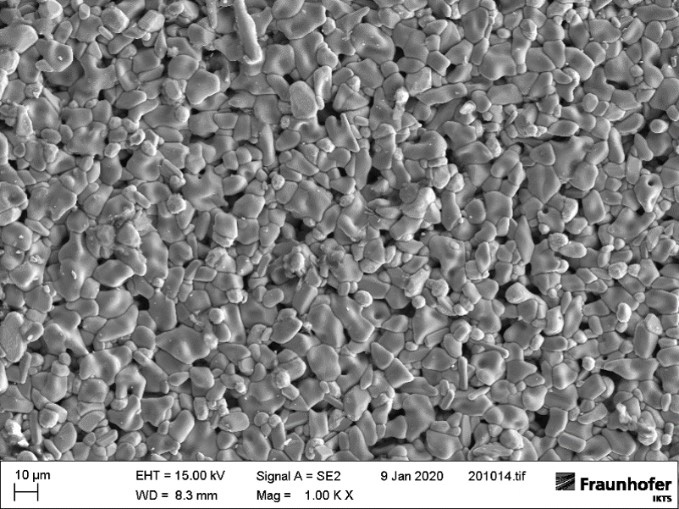

Carbon-silicon anode material produced by Glatt powder synthesis

Case study: Silicon-based anode material

Carbon-based anodes are dominant on today’s market. However, the drive for higher capacities is increasingly forcing manufacturers to find alternative solutions. Silicon in particular is predestined for this application due to its good availability and high specific capacity. However, the technical challenge using silicon is its volume change that occurs during the charge/discharge cycle, which in the long run leads to fracture of the particles, loss of contact to the current sink and continuous erosion of the boundary layer between silicon and electrolyte.

A promising approach is therefore the use of silicon-carbon composite materials: An interconnected structure made of carbon compensates for the volume change of the silicon and the elastic layer protects the Silicon from direct contact with the electrolyte.

To create these particles, Silicon, a dissolved organic binder and, if necessary, other additives are prepared in a suspension and sprayed in the synthesis reactor. Depending on the process control, the silicon particles can be either agglomerated by the polymer or just coated. If required, the binder or layer phase can also be heat treated (e.g. cyclized) in the same process step via an appropriate temperature regime.

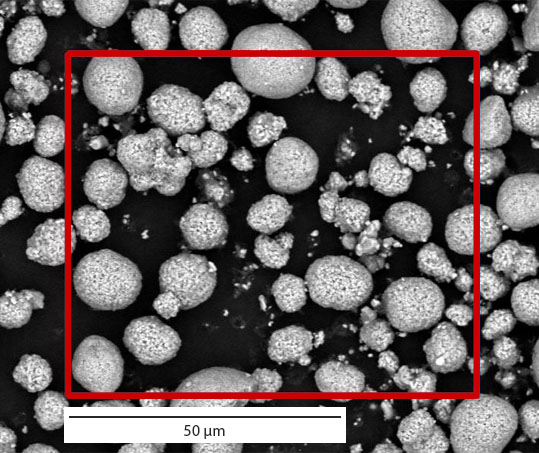

New battery materials by Powder Synthesis: sintered LLZO membrane

Case study: Solid oxide electrolytes

The trend to higher safety in batteries is toward solid-state batteries. The most difficult part of this is developing a solid electrolyte that can compete with the ionic conduction of liquid electrolytes. Two main concepts are currently being pursued for this, involving either oxide or sulfide ionic conductors.

Glatt powder synthesis is used in various projects for the development of solid oxide electrolytes, especially lithium lanthanum zirconium oxide (LLZO) and doped variants thereof. The primary goal is to investigate the simplification of synthesis, the reduction of manufacturing costs and the development of an effective concept for up-scaling.

As a result, LLZO solutions based on low-cost raw materials were implemented using powder synthesis. The adjustment of particle size, bulk density and crystal structure was achieved by adjusting various parameters. Further processability of the powders into ceramic films was also demonstrated. Conventional processes for the production of LLZO are usually in the gram or kilogram range. The advantage of the described technology is that the process can be easily scaled up to production scales.

Case study: Coated cathode materials to increase long-term stability

During charging and discharging, cathode materials are subject to different phenomena of degradation. Interactions with the electrolyte lead, among others, to the dissolution of active elements or the formation of thermodynamically unstable interfaces. A novel approach is to coat the cathode materials to avoid direct contact with liquid or solid electrolytes. Such protective layers can be applied using Glatt Powder Synthesis. Inorganic compounds can be applied, and the desired crystallinity of these coatings can be achieved in the same process run.

EDX mapping of a Li3PO4 coating on NMC 622 using the tracer elements phosphorus (coating) and manganese (core)

Glatt powder synthesis is ideally suited for coating fine powder materials as feedstock for lithium-ion batteries. Rapid performance degradation of high-performance batteries can thus be prevented and the durability of the cathodes demonstrably increased.

Published article: New Battery Material by Powder Synthesis

Powder synthesis represents a novel process for the production, activation and coating of battery powder materials. By using a pulsating hot gas flow with adjustable frequencies and amplitudes, powders of the highest quality can be produced.

Whereas the battery capacity of computers and mobile devices has reached an acceptable level, the expectations of electromobility customers in terms of range and charging speed are not being met. The search for solutions to remedy these deficits is increasingly becoming a driver for innovative new battery materials. With Glatt powder synthesis, a novel type of cutting-edge technology is available that is already being used in the production, activation and coating of new types of battery materials.

» Authors: Dr.-Ing. Viktor Drescher, Dr. rer. nat. Thomas Jähnert, Dr. rer. nat. Johannes Buchheim

» originally published in the magazine ‘Interceram’, issue 2/2021, Springer Fachmedien Wiesbaden GmbH

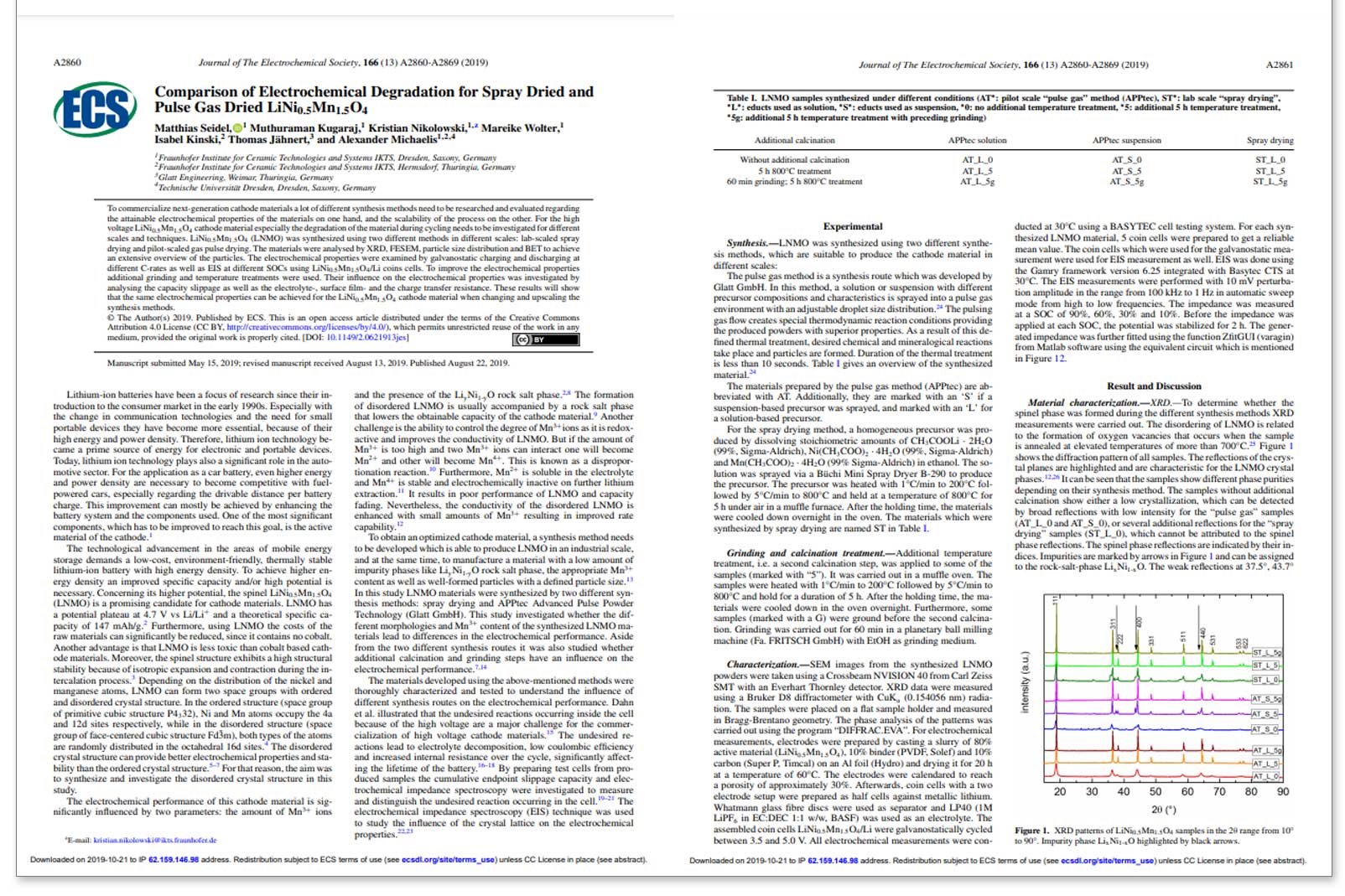

Published article: Comparison of Electrochemical Degradation for Spray Dried and Pulse Gas Dried LiNi0.5Mn1.5O4

To commercialize next-generation cathode materials a lot of different synthesis methods need to be researched and evaluated regarding the attainable electrochemical properties of the materials on one hand, and the scalability of the process on the other. For the high voltage LiNi0.5Mn1.5O4 cathode material especially the degradation of the material during cycling needs to be investigated for different scales and techniques. LiNi0.5Mn1.5O4 (LNMO) was synthesized using two different methods in different scales: lab-scaled spray drying and pilot-scaled gas pulse drying.

- originally published in: Journal of The Electrochemical Society, 166 (13) A2860-A2869 (2019)

Further information on applications of Glatt powder synthesis can also be found in the following publications:

March 2022: Glatt expands technology center with new laboratory plant for powder synthesis

June 2021: Fraunhofer IKTS operates world’s first flameless high-temperature powder synthesis plant

Published article: ‘Coated zirconia for medical technology by specialized powder synthesis’ PDF, German

Published article: ‘From Hot Gas Stream to Matt Finish by Glatt Powder Synthesis’ PDF, English

Published article: ‘Glatt Powder Synthesis – Pioneering Process for Groundbreaking Particle Synthesis’ PDF, English