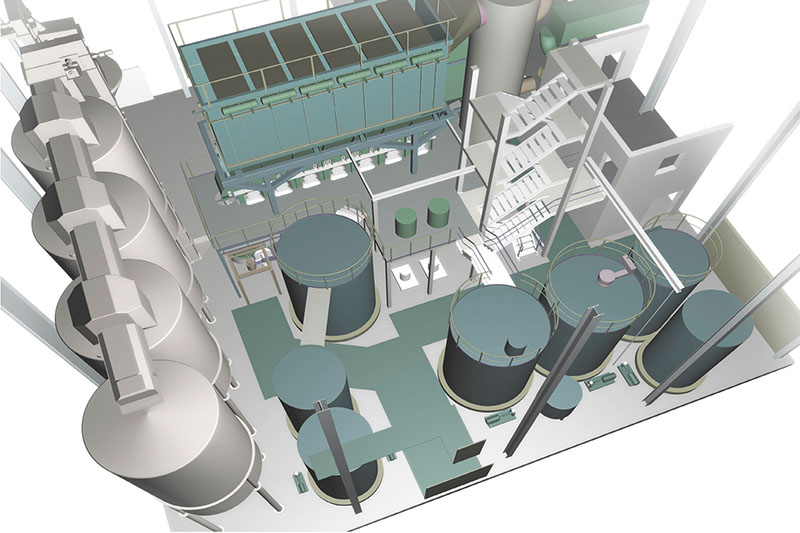

Glatt Engineering: 3D planning of the production facility including the Glatt Fluid Bed Granulator GFG 850 for continuous spray granulation of potash

Construction of a new complete production facility for continuous fluid bed granulation of potash, Germany, 2001

20.000 tons per year of various potash products of the highest possible quality by means of an advanced fluid bed granulation system

After olny 10 months construction time a modern production line for potash has been started up in December 2001 in Stassfurt. It produced 20.000 tons per year of various potash products of the highest possible quality by means of an advanced fluid bed granulation system.

The technology has been developed by an expert team for continuous fluid bed processing from the Stassfurt Potash GmbH & Co, the University of Magdeburg and Glatt Ingenieurtechnik at Weimar. The latter have been the general contractor for this 6.5 million € green-field turn-key project, involving the business units engineering, plant construction and installation supported by local sub-contractors.

The plant comprised 1400 m² for laboratories, offices and social rooms, more than 3000 m² storage floor and a 625 m² production hall, where in 10,000 m³ all processing equipment was installed.

The project did also include the modernization of the existing carbonization plant producing the potash solution from caustic potash and CO2. The CO2 was part of the exhaust of the power plant of the facility. Using it was also solving an environmental concern. The potash solution was then filtered, fluid bed granulated and dried and conveyed to a vibration screen. The hourly product output of 2.5 tons was then transported by a bucket elevator into 3 x 80 m³ silos. Hence no more hard physical labor and inhaling clouds of dust for the 22 employees.

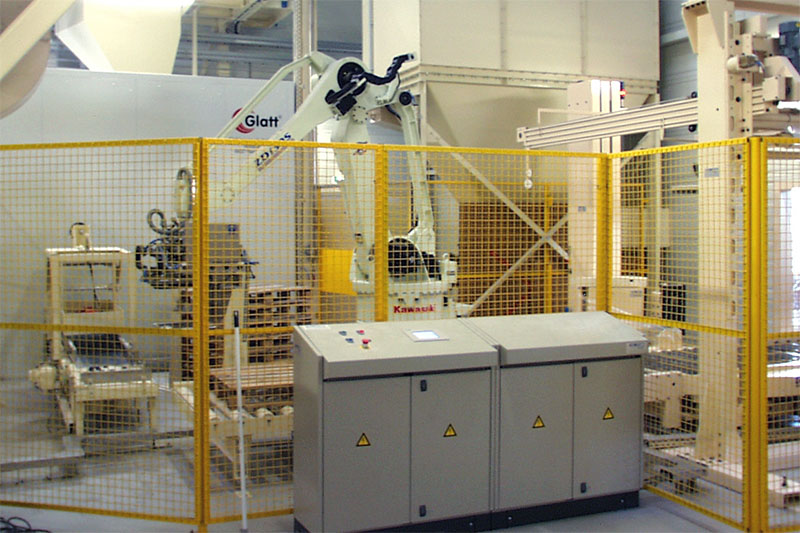

There were three different packaging lines. A robot controled the packing of the dust-free granules into 25 kg bags which are then automatically loaded on pallets. Larger quantities could optionally be filled into big-bags of 1000 kg or into silo trucks.

Core of the process was the continuous Glatt fluid bed granulator, type GFG 850, designed for an output of 2500 kg/h. With a total bottom screen area of 8.5 m² two processes were accomplished; spray granulation and subsequently cooling. The spraying system was designed to work with pneumatic and hydraulic nozzles alternatively. This – and the adjustment of process parameters – meant a high flexibility of the new plant giving the possibility to meet product quality demands of various customers listing here only some examples:

- potash, calcinated with a carbonate content ≥ 99,4 % as well as potash, hydrated with a carbonate content ≥ 84.5 uo to 85.0 %

- at different grain sizes, like 0.2 – 1.6 mm, 0.2 – 1.0 mm and 0.2 – 2.0 mm

- and bulk densities of 850 kg/m³, 900 kg/m³ and 1,200 kg/m³

The process air was cleaned with an internal filter system, kept all dust within the granulator. When cleaning the filter with a pulse back, the dust fell into the fluid bed and was integrated into the granules.

The gas heater allowed process air temperatures between 120 and 400 °C. An exhaust air heat exchanger recovered 980 kW at a fresh air temperature of 20 °C, such saving 25 % energy compared with traditional processing. A central process control system with 16 different visualization displays provided for in-process monitoring and controlling, either on-site or remotely (ex Weimar).

After the commissioning of the plant the production was demonstrated at full capacity. All values, agreed upon in the contract – throughput, product quality and energy consumption – were met. After the hand over of the plant Glatt process engineers assisted in establishing the production process for alternative products, demonstrating the capabilities and flexibility of the plant to the personal who were soon able to run the plant without any support by Glatt.

Please note: Due to changed market conditions, operations in Staßfurt have now been discontinued.

Construction of a new complete production facility for continuous fluid bed granulation of potash, Germany, 2001

Project details:

| Location | Stassfurt, Germany |

| Timescale | 08/2000 – 09/2001 |

| Product | potash (potassium carbonate K2CO3) |

| Capacity | 20,000 tones/year |

| Building | new production building + modernization of the existing calcination plant |

| Technology | continuous fluid bed spray granulation and cooling in the Glatt fluid bed granulator of the type GFG 850 |

| Scope of Glatt supply and services | turnkey project = product trials, feasibility study, process development, complete engineering including building, project management, delivery, assembly/installation, commissioning/start-up, training of operators |

Production facility including the Glatt GFG 850 fluid bed granulator for continuous spray granulation of potash

Transport of the Glatt GFG 850 fluid bed granulator for continuous spray granulation of potash

Construction site of the production facility for continuous spray granulation of potash

Placement of the Glatt GFG 850 fluid bed granulator for continuous spray granulation of potash

Closing the building at construction site of the production facility for continuous spray granulation of potash

Preparation of the suspension, continuous spray granulation of potash, Glatt Fluid Bed Granulator GFG 850

Spray system of the Glatt fluid bed granulator GFG 850 for continuous spray granulation of potash

Operator platform, production facility for continuous spray granulation of potash

Packaging system of the production facility for continuous spray granulation of potash

Published article: ‘Growing the German phosphate industry’. PDF, English

Published article: ‘Process Technologies to Optimize Detergent Manufacturing’. PDF, English

Published article: ‘Improved performance for crop protection products’, PDF, English

Published article: ‘A Fluid Bed Approach – Case study on the economical production of urea-based fertilizers can be achieved using fluidised bed technology’ PDF, English

Published article: ‘Integrated approach saves costs – Design and operation of energy-efficient fluid bed systems’ PDF, English