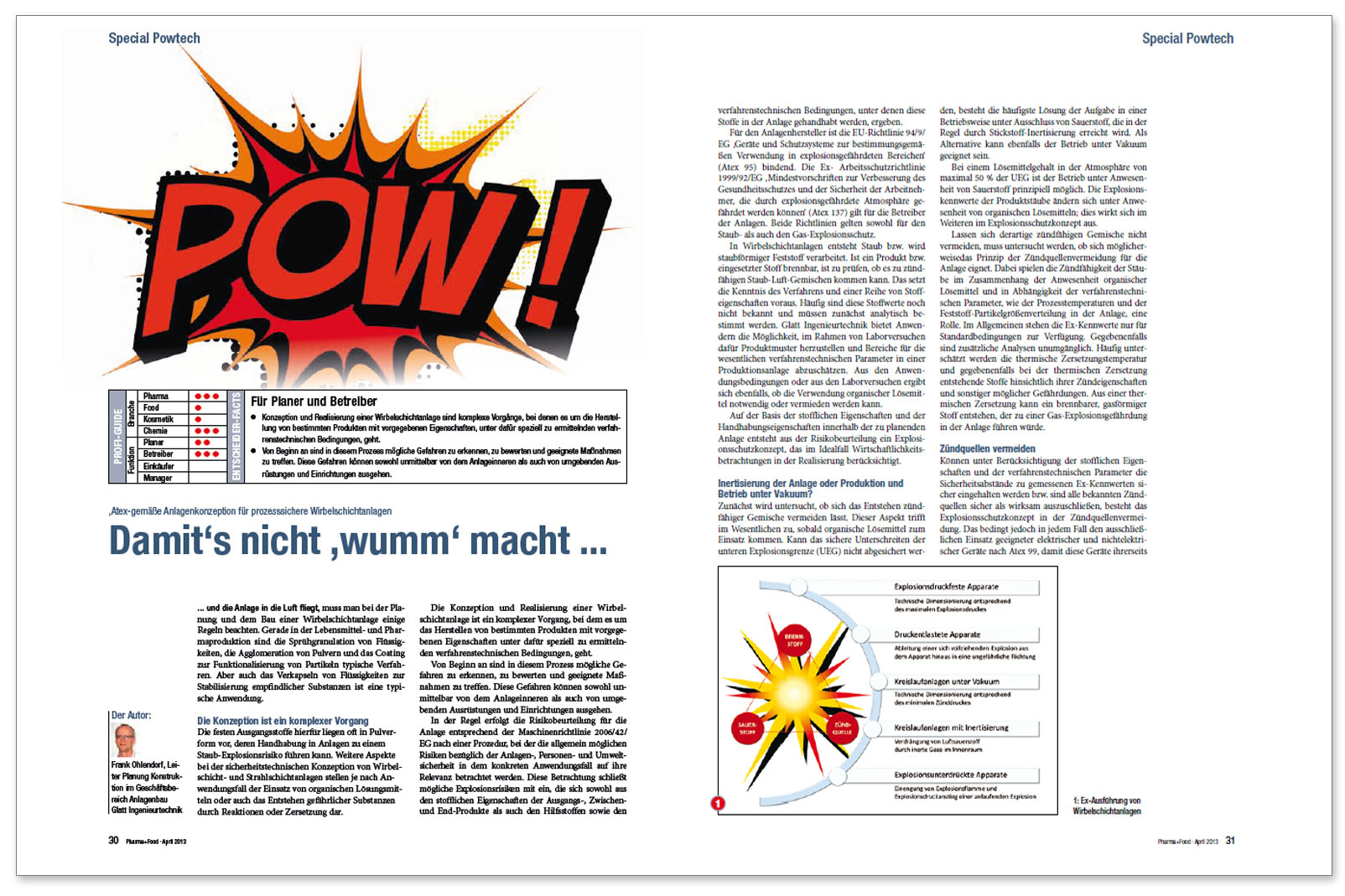

Atex-compliant system design for high process reliability (German article)

So that it will not go “boom” and the plant will blow up! This must be taken into account in advance when planning and designing a plant. Fluid bed and spouted bed systems of various designs and sizes are used in many branches of industry for product design and the production or refinement of granulates and pellets. The solid starting materials for this are often in powder form, the handling of which in plants can lead to a dust explosion risk. Other aspects of the safety design of fluid bed and spouted bed systems are, depending on the application, the use of organic solvents or the formation of hazardous substances through reactions or decomposition.

The conception and realization of a fluidized bed plant is a complex process, which involves the production of certain products with specified properties under process engineering conditions that have to be specially determined for this purpose.

From the very beginning of this process, potential hazards must be identified, evaluated and appropriate measures taken. These hazards can emanate both directly from the inside of the plant and from surrounding equipment and facilities. (article in German language)

- Author: Frank Ohlendorf, Head of Planning & Design, Process Technology Food, Feed & Fine Chemicals, Glatt Ingenieurtechnik GmbH

- originally published in the trade magazine ‘Pharma+Food’, issue 02/2013, Hüthig GmbH

and Atex-gemäße Konzeption von Wirbelschichtanlagen (pharma-food.de)

Further information on this topic and related topics can also be found in the following publications:

Published article: ‘A matter of gas flow management – Microencapsulation of essential oils by spray granulation unsing spouted bed technology’ PDF, English

Published article: ‚Forward-looking plant planning – How pre-engineering can bring ideas to market faster‘ PDF, English

Published article: ‘Technologies à lit fluidisé / Fluid bed and spouted bed technology’ PDF, English/French

Published article: ‘Hot-melt applications for the food and beverage industry – How to safely stabilize vitamins and probiotics’ PDF, English

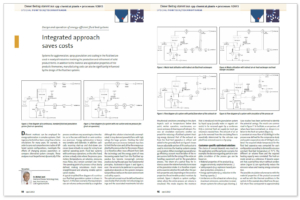

Glatt Technical Paper: ‘Integrated approach saves costs – Design and operation of energy-efficient fluid bed systems’. PDF, English

Copyright: Konradin-Verlag Robert Kohlhammer GmbH

Copyright: Konradin-Verlag Robert Kohlhammer GmbH Copyright: Hüthig GmbH

Copyright: Hüthig GmbH