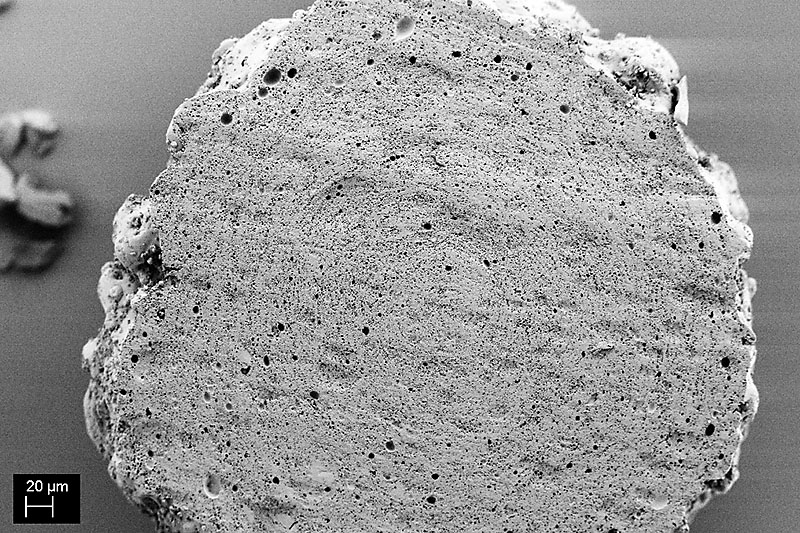

Essential oil, matrix micro encapsulation, REM

Protecting and drying hydrophobic substances by micro encapsulation

Essential oils, carotenoids, flavors or even hydrophobic plant substances are challenging candidates in terms of formulation and process due to their chemical structure. Such substances are usually extremely sensitive to oxidation and to higher temperatures. For many applications, these substances are needed in solid formulations, for example in flavored teas and dessert mixes or as essential oils, neutral in taste and stable over time as additives in baby food.

The micro encapsulation process combines the inclusion of hydrophobic substances in a matrix with granulation and drying.

In the first process step, the oil is emulsified and encapsulated with an encapsulation material that protects against oxidation – such as modified starches, hydrocolloids or even proteins. Stabilization of the emulsion has a decisive influence on product quality. It prevents the microcapsules from being destroyed in the subsequent process. The contents of the capsules thus remain protected from oxidation.

Fluid bed technology and spouted bed technology are particularly suitable for drying at moderate product temperatures. The latter scores with shorter residence times. Both technologies enable the production of compact granules. The reduction of the surface area and the dense matrix reduce the attack surface for oxygen and improve the long-term stability. The use of nitrogen as a process gas enables further optimization of product quality. As with all spray granulation processes, the particle size of the end product is freely adjustable.

The variety of process variants within fluid bed and spouted bed technology offers the whole spectrum from drying to controlled release of active ingredients.

At the Glatt Technology Center in Weimar, we work with you to determine the optimum process conditions for your product in feasibility trials for product development. Various laboratory facilities and comprehensive analytical equipment are available for this purpose. On our pilot plants, we optimize the process and scale it up reliably to a stable and economical production scale. The results from this form the basis for the design and construction as well as the erection of your fluid bed or spouted bed plant, tailored to your requirements. As an alternative to our own process technology, we offer you the outsourcing of your production by means of contract manufacturing at Glatt.

How to Tame Recalcitrant Ingredients with Technological Processes

Plant-based functional ingredients behave differently than manufacturers of nutraceuticals and cosmetic products would like. Innovative processes such as double micro encapsulation can help them to overcome bioavailability and solubility challenges.

- Authors:

Gudrun Ding, Head of Business Development Process Technology, Glatt Ingenieurtechnik GmbH

Francesca Zanoni, Research and Development Manager, Sphera Encapsulation

Isabel Gómez, Global Marketing Manager, Nutraceutical Ingredients Lubrizol Life Science, Health - originally published in the magazine ‘Nutraceutical Business Review’, issue August/2021, HPCi Media Limited

Further information on this topic and related topics can also be found in the following publications:

Published article: ‘With short time-to-market from process development directly to contract manufacturing’ PDF, English Reprint

Published article: ‘The gentle processing of highly volatile oils by fluid bed and spouted bed technology’ PDF, English

Published article: ‘Spray micro encapsulation of sensitive substances in matrix form – An overview of essential oil and vitamin case studies’ PDF, English

Published article: ‘Optimizing end products with finely tuned process parameters’ PDF, English

Published article: ‘A matter of gas flow management – Micro encapsulation of essential oils by spray granulation unsing spouted bed technology’ PDF, English