Lactobacilli, layering and enteric protective coating

Drying, encapsulation and immobilization of microorganisms

The health-promoting effect of probiotics has been proven by various studies in recent years and is undisputed. The multitude of dietary supplements but also enriched foods is a sign of this. The aim of all these products is the colonization of microorganisms in the intestine to support the existing intestinal flora. The efficiency of the products, especially the number of surviving microorganisms, is crucial for this. The diversity of bacterial strains, their temperature sensitivity and the specific requirements of their milieu rarely allow standard solutions. After fermentation, the organisms must be converted to a storage-stable state – usually by freeze-drying. Sometimes other drying methods are successful.

The drying and stabilization of microorganisms in the fluidized bed was investigated in a case study using the example of a lactobacillus strain. The result proves that only a close interaction of formulation, process control and plant design is target-oriented.

With its spouted bed technology, Glatt has developed and patented a special process for encapsulating and immobilizing microorganisms. The excellent heat and mass transfer conditions enable gentle drying of the microorganisms.

To improve the survival rate, the formulation can be enriched with various protective substances and prebiotics. It is possible to enclose the product directly afterwards with an enteric coating.

At the Glatt Technology Center in Weimar, we work with you to determine the optimum process conditions for your product in feasibility trials for product development. Various laboratory facilities and comprehensive analytical equipment are available for this purpose. On our pilot plants, we optimize the process and scale it up reliably to a stable and economical production scale. The results from this form the basis for the design and construction as well as the erection of your fluid bed or spouted bed plant, tailored to your requirements. As an alternative to our own process technology, we offer you the outsourcing of your production by means of contract manufacturing at Glatt.

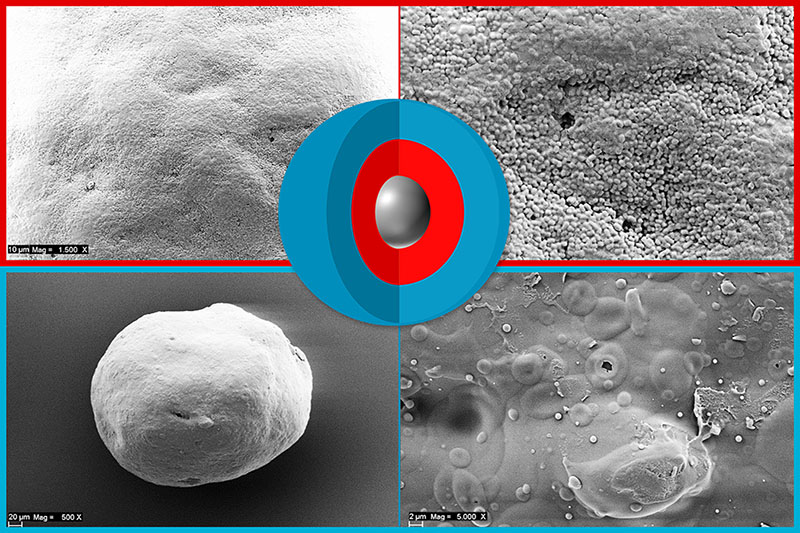

Lactobacilli, layering, 10 µm, 1500-fold

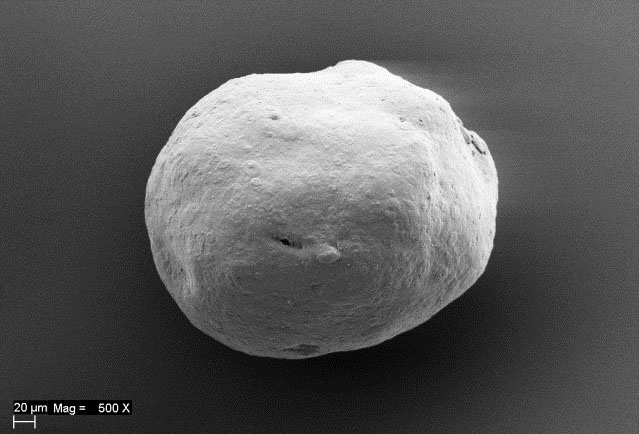

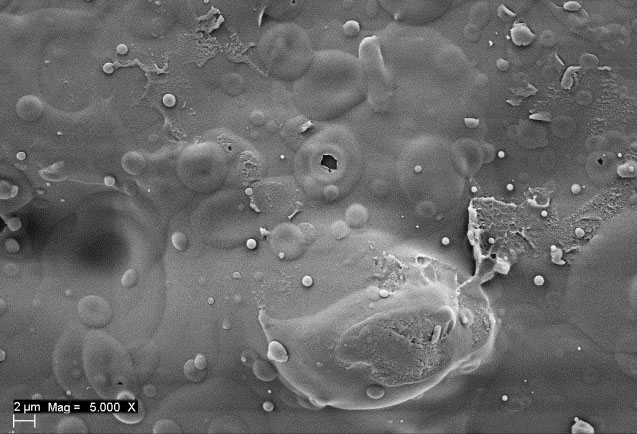

Lactobacilli, layering, 20 µm, 5000-fold

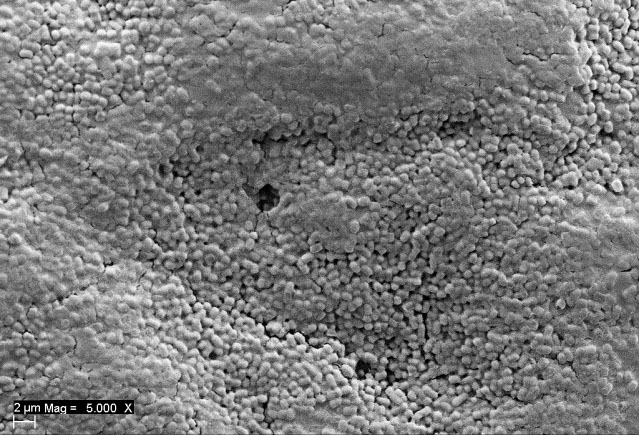

Lactobacilli, enteric coating, 20 µm, 500-fold

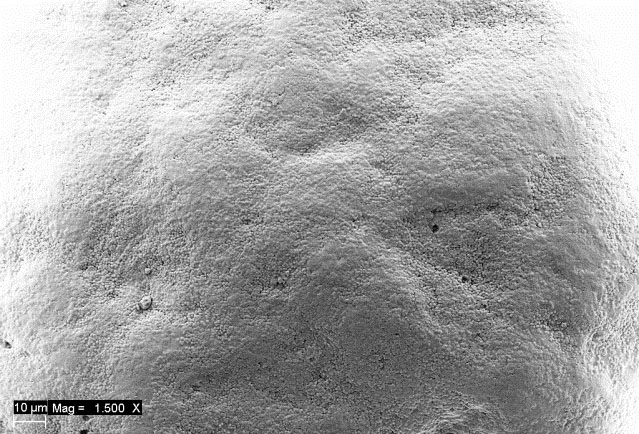

Lactobacilli, enteric coating, 10 µm, 5000-fold

Further information on this topic can also be found in the following publications:

Published article: ‘Customized properties – drying and stabilization of microorganisms by fluid bed and spouted bed technology’ PDF, German

Published article: ‘Hot-melt applications for the food and beverage industry – How to safely stabilize vitamins and probiotics’ PDF, English

Published article: ‘Enhancing product properties with fluid bed and spouted bed technologies’ PDF, English

Published article: ‘Fluidized bed solutions for optimized ingredient production’ PDF, English

Published article: ‘Protecting sensitive substances effectively – Particle design by fluidized bed and spouted bed processes’ PDF, German