Production plant for phosphate fertilizers, Glatt PHOS4green, 2021, Germany

Phosphorus recovery on an industrial scale at SERAPLANT, Haldensleben

First large-scale production for 60,000 tons of phosphate-containing straight and compound fertilizers being recyclates from sewadge sludge ashes.

In spring 2021, development partner SERAPLANT, a fertilizer manufacturer based in Saxony-Anhalt, Germany, started operating a Glatt PHOS4green production plant. The produced phosphorus-containing fertilizers are recyclates from a phophorus recovery technology from sewadge sludge ashes. The new plant is designed for an annual production of 60,000 tons of phosphate-containing straight and compound fertilizers. At the heart of the process is the AGT® 750 spray granulation unit. PHOS4green is the first recycling process for phosphorus recycling to be implemented on an industrial scale anywhere in Germany. The target groups are agricultural businesses in conventional and organic farming, agricultural and horticultural wholesalers and the fertilizer industry. Glatt was commissioned with the planning and implementation of the complete plant technology, from raw material delivery – via suspension preparation and subsequent fluid bed granulation – to finished fertilizer. According to a press release dated 08.11.2019, SERAPLANT invested 20 million euros in the construction with support from the state of Saxony-Anhalt. Additional funding of almost five million euros came from the funding program of the joint task “Improvement of the regional economic structure” (GRW). The GRW is part of the overall German support system for structurally weak regions under the auspices of the Federal Ministry of Economics. The innovative production facility will create more than 20 new jobs, which will be filled in the coming months.

Construction of a factory for the production of fertilizer granules from sewage sludge ash

Project details:

| client | Seraplant GmbH in Haldensleben, Germany |

| Timescale | 06/2018 – 1st quarter 2021 |

| Product | Fertilizer granules |

| Capacity | 60,000 t/year with 330 working days/year and 3 shifts |

| Building | New Building |

| Technology | Continuous spray granulation in the Glatt fluid bed granulator of the type AGT® 750 |

| Scope of Glatt supply and services | Complete planning and project engineering incl. authorization engineering, delivery of all equipment, assembly and installation, direction for commissioning |

- approx. 80 main equipment and 2 package units

- production building 18 m x 18 m steel construction, 4 floors

- functional annex reinforced concrete 8 m x 18 m, 2 floors

- aggregate storage in product storage hall

- outdoor installation for ash storage, acid storage, exhaust air treatment

- approx. 190 measuring devices and approx. 150 controlled valves

- approx. 1.5 MW installed electrical power

Glatt Engineering: 3D view for the industrial production plant for the production of phosphate fertilizer

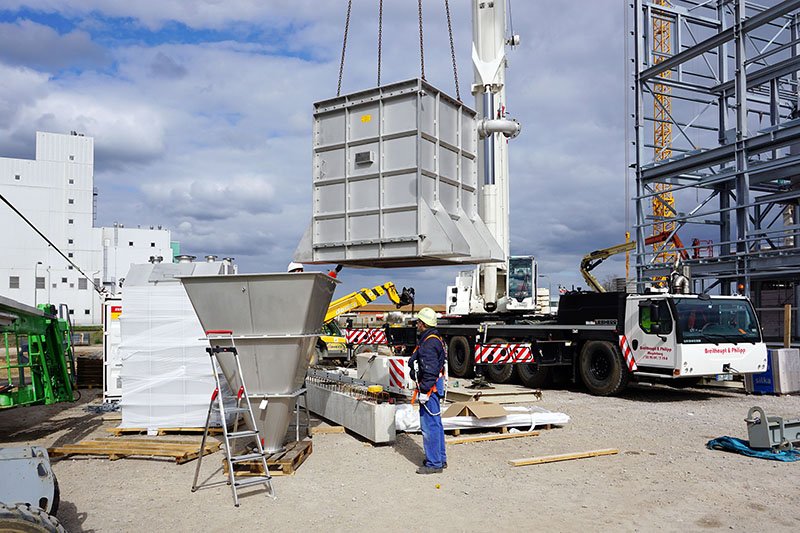

Glatt Engineering: Implementation of the industrial production plant for the manufacture of phosphate fertilizer in Haldensleben, Germany (August, 2020)

Glatt Engineering: Flow diagram of the industrial production plant for the manufacture of phosphate fertilizer in Haldensleben, Germany

Insertion of the fluid bed granulator

Insertion of the fluid bed granulator

Insertion of the fluid bed granulator

Installation of the fluid bed granulator

Delivery of the filter

Insertion of the filter

Insertion of the filter

Insertion of the filter

Placement of the cooling system

Placement of the ash silos

Placement of the acid tanks

Installed ash silos and acid tanks

Installation of the filter

Installation of the suspension system

Installation of the air supply system

Published article: ‘Growing the German phosphate industry’. PDF, English

Published article: ‘Improved performance for crop protection products’, PDF, English

Technical article: ‘Like a phoenix from the ashes’. A recovery technology that releases phosphate from sewage sludge ashes and converts it into ready-to-use fertilizers. PDF, English

Published article: ‘Fomulation For Success – Fluid Bed Systemes as Key for the Production of Speciality Fertilizers’, PDF, English

Published article: ‘A Fluid Bed Approach – Case study on the economical production of urea-based fertilizers can be achieved using fluidised bed technology’ PDF, English