Vitamin B12 pellet, encapsulated and protected by film coating in the fluid bed Wurster

Increased transport and storage stability: Reduced sensitivity to light. More resistance to oxygen, moisture and higher temperatures.

Vitamins are essential substances and must be regularly supplied to the organism. A distinction is made between hydrophobic and hydrophilic substances. While fat-soluble vitamins are accumulated in the body, excess water-soluble substances are excreted. Due to their reactivity, vitamins are very sensitive to oxidation, light and moisture. Enriched products therefore usually contain increased vitamin levels to compensate for degradation during storage.

Processes such as microencapsulation, layering of active ingredients onto carriers, or coating with protective polymers can increase stability and thus reduce the amount of vitamin needed. A typical example is sustained-release vitamin C or folic acid pellets with a protective coating.

With layering on carriers, vitamin contents but also trace elements can be precisely dosed.

There is a wide variety of process variants based on fluid bed technology or spouted bed technology. At the Glatt Technology Center in Weimar, we work with you to determine the optimum process conditions for your product in feasibility trials for product development. Various laboratory facilities and comprehensive analytical equipment are available for this purpose. On our pilot plants, we optimize the process and scale it up reliably to a stable and economical production scale. The results from this form the basis for the design and construction as well as the erection of your fluid bed or spouted bed plant, tailored to your requirements. As an alternative to our own process technology, we offer you the outsourcing of your production by means of contract manufacturing at Glatt.

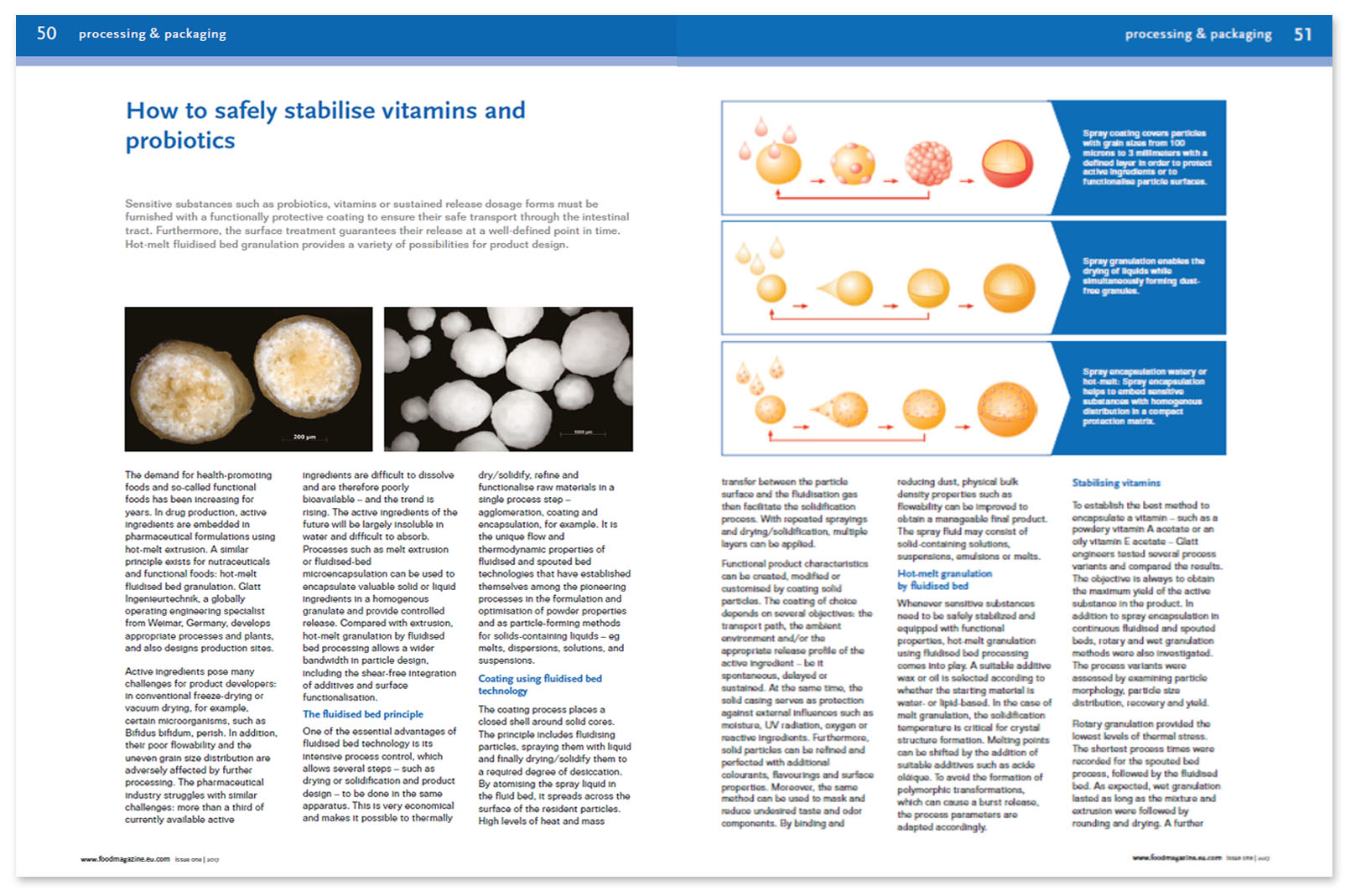

Published article: Hot-melt applications for the food and beverage industry – How to safely stabilize vitamins and probiotics

Sensitive substances such as probiotics, vitamins or sustained release dosage forms must be furnished with a functionally protective coating to ensure their safe transport through the intestinal tract. Furthermore, the surface treatment guarantees their release at a well-defined point in time. Hot-melt fluidized bed granulation provides a variety of possibilities for product design.

» Author: Dr. Michael Jacob, Head of Process Technology Food, Feed & Fine Chemicals, Glatt Ingenieurtechnik GmbH

» originally published in the trade magazine ‘foodeurope’, issue 01/2017, Hoskins & Fall Publishing

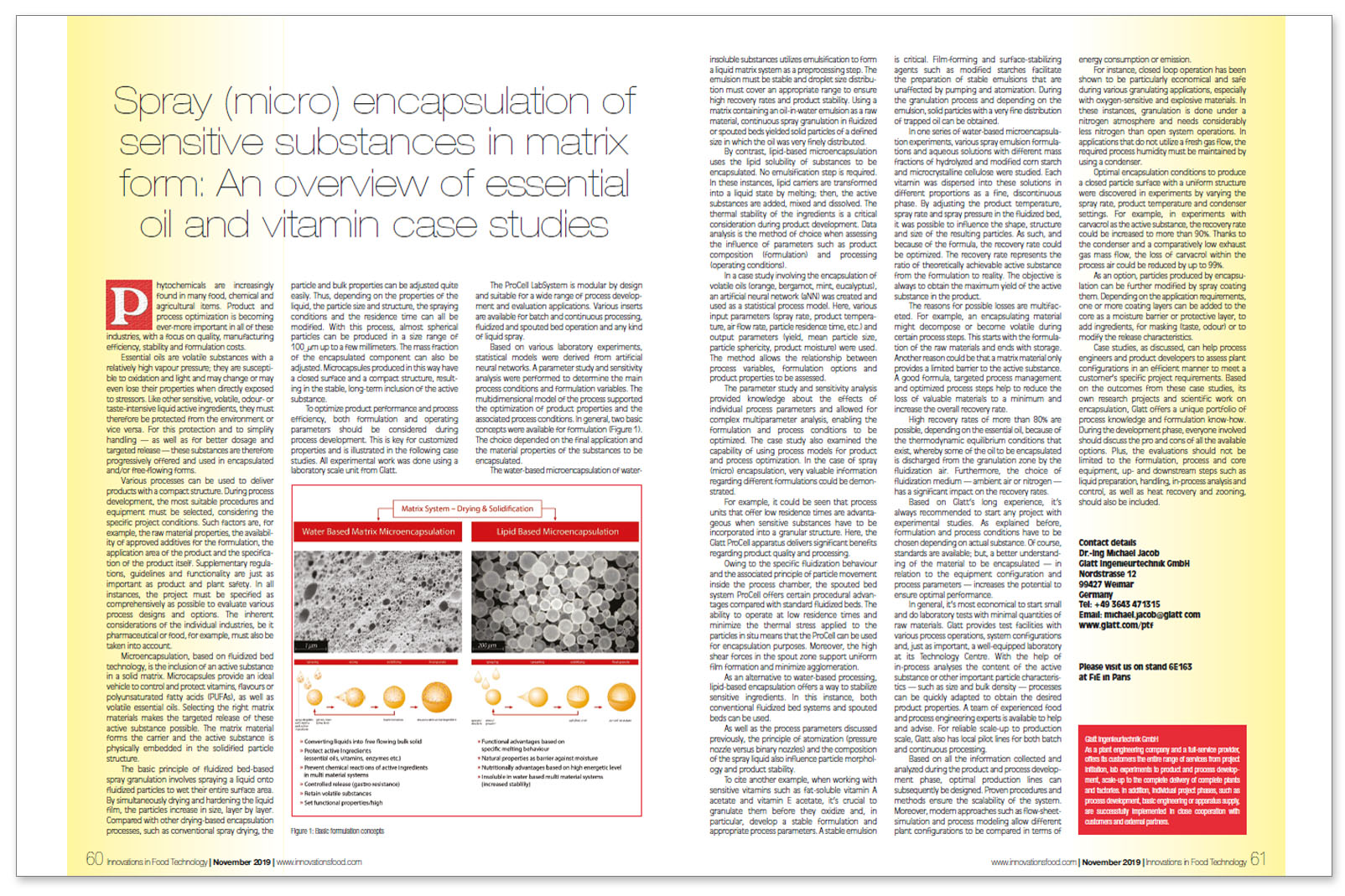

Published article: Spray (micro)encapsulation of sensitive substances in matrix form – An overview of essential oil and vitamin case studies

Phytochemicals are increasingly found in many food, chemical and agricultural items. Product and process optimization is becoming ever-more important in all of these industries, with a focus on quality, manufacturing efficiency, stability and formulation costs. Various processes can be used to deliver products with a compact structure. During process development, the most suitable procedures and equipment must be selected, considering the specific project conditions. Case studies, as discussed, can help process engineers and product developers to assess plant configurations in an efficient manner to meet a customer’s specific project requirements.

» Author: Dr. Michael Jacob, Head of Process Technology Food, Feed & Fine Chemicals, Glatt Ingenieurtechnik GmbH

» originally published in the trade magazine ‘Innovations in Food Technology’, issue 11/2019

Further information on this topic can also be found in the following publications:

September 2021: New fluid bed options for solvent-based processes and products

Published article: ‘Fluid bed and spouted bed technologies – Optimising functional ingredients for enhanced nutrition’ PDF, English

Published article: ‘Optimizing end products with finely tuned process parameters’ PDF, English

Published article: ‘Food, feed and pet nutrition:

a convergence of industries’ PDF, English

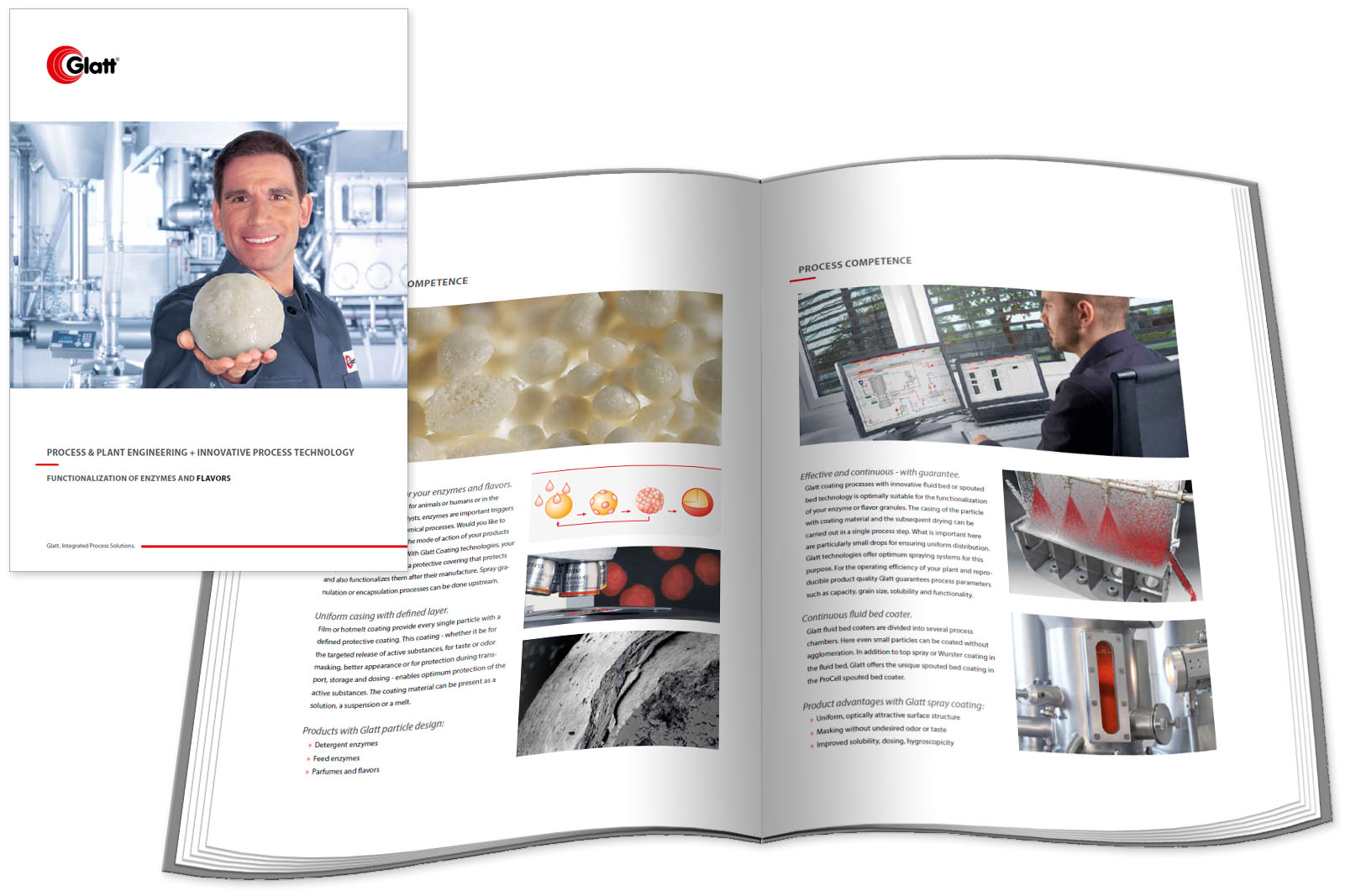

Flyer A4: Glatt Functionalization of Enzymes and Flavors, PDF, English