Beta-carotene pellet, microencapsulation based on spray granulation in the fluid bed or spouted bed

A plus in safety: avoidance of ignition sources, nitrogen as process gas, vacuum operation or explosion-proof design of the system.

The use of organic solvents is avoided as far as possible. However, processes in fluid bed systems or spouted bed systems sometimes require organic solvents. This is the case when it comes to dissolving or extracting hydrophobic substances or when improved bioavailability is to be achieved through nanocapsulation. Aspects such as residual solvent contents in the ppm range and their recovery are further challenges.

In principle, the evaporation of solvents leads to explosive mixtures. If an ignition source is added, there is a risk of explosion.

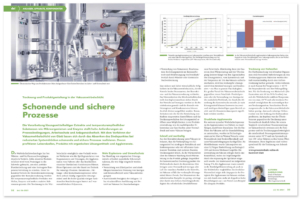

Various precautions counteract this. The first step is to avoid ignition sources, among other things by grounding moving parts. The second step is to reduce oxygen below the explosion limit. The exclusion of oxygen can be achieved with nitrogen as the process gas or by applying a vacuum. In both cases, the process operates in closed-loop mode. The solvent is condensed and can be recycled.

The fluidized bed under vacuum offers a further advantage, as the lowering of the boiling point facilitates the evaporation of the solvent. This benefits temperature-sensitive products in particular.

If it is necessary for product quality to operate in fresh air/exhaust air mode, for example in the case of solvent coatings, another plant concept comes into consideration. The fluid bed system is designed to withstand a pressure surge of 12 bar, and the supply and exhaust air areas are sealed off by quick-acting valves in the event of an explosion. The process chamber itself withstands the pressure rise of an explosion.

We will be pleased to support you in the realization of your product innovations. At the Glatt Technology Center in Weimar, we work with you to determine the optimum process conditions for your product in feasibility trials for product development. Various laboratory facilities and comprehensive analytical equipment are available for this purpose. On our pilot plants, we optimize the process and scale it up reliably to a stable and economical production scale. The results from this form the basis for the design and construction as well as the erection of your fluid bed or spouted bed plant, tailored to your requirements. As an alternative to our own process technology, we offer you the outsourcing of your production by means of contract manufacturing at Glatt.

Further information on this topic can also be found in the following publications:

September 2021: New fluid bed options for solvent-based processes and products

Published article: ‘Atex-compliant system design for high process reliability’ PDF, German

Published article: ‘Better safe than sorry – Design safety for fluid bed systems’ PDF, German

Published article: ‘Outsourcing – Trust in competent partners’ PDF, English

Published article: ‘Gentle and safe processes – Drying and product design in the vacuum fluid bed’ PDF, German