Improve Storage Stability by Coating

Functional coatings by means of film coating, lipid or hot melt coating

Coatings to protect against external influences such as moisture, UV radiation, oxygen or to separate reactive ingredients

Sensitive substances such as vitamins, enzymes, oxidation-sensitive and hygroscopic substances improve their storage stability with a functional, protective coating.

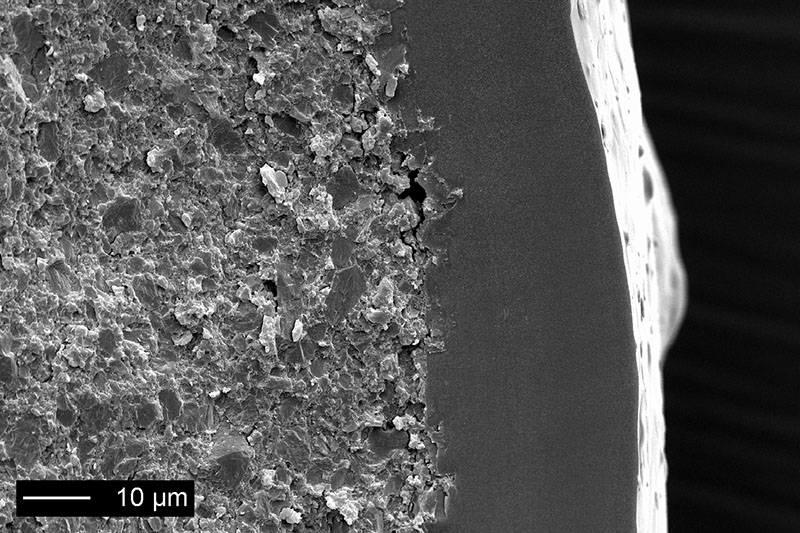

The stability of substances depends not only on their properties. The conditions of the environment, such as temperature, humidity, light, etc., also play an essential role in this regard. The uniform coating by a film coating or lipid/hot melt coating of product particles can positively influence their processability and their stability.

Hygroscopic products, for example, are encapsulated in a so-called hot melt coating by spraying on a fat or wax. Moisture no longer has a chance to dissolve the product surface. The product remains free-flowing and free-flowing. Light-sensitive products, on the other hand, can be covered with polymer solutions containing suitable pigments.

One of the most common applications is the separation of different active ingredients in mixtures. Examples of this are classic powder detergents containing a wide range of reactive substances, from enzymes and bleach activators to oxidation-sensitive perfume oils.

Which film formers are used depends on the requirements, the industry, the product properties (e.g. whether powder or granules) and the economic aspects.

There is a wide variety of process variants based on fluid bed technology or spouted bed technology. At the Glatt Technology Center in Weimar, we work with you to determine the optimum process conditions for your product in feasibility trials for product development. Various laboratory facilities and comprehensive analytical equipment are available for this purpose. On our pilot plants, we optimize the process and scale it up reliably to a stable and economical production scale. The results from this form the basis for the design and construction as well as the erection of your fluid bed or spouted bed plant, tailored to your requirements. As an alternative to our own process technology, we offer you the outsourcing of your production by means of contract manufacturing at Glatt.

Further information on this topic can also be found in the following publications:

Published article: ‘Process Technologies to Optimize Detergent Manufacturing’. PDF, English

Published article: ‘Hot-melt applications for the food and beverage industry – How to safely stabilize vitamins and probiotics’ PDF, English

Published article: ‘Protected by a shell – Optimization of active ingredients by encapsulation or coating’ PDF, German

Published article: ‘Fluid Bed Coating – Changing Properties of Solids as Desired’ PDF, German

Published article: ‘It’s all in the combination – Coating in the food and pharmaceutical industries, part 1’ PDF, German