It is not uncommon for special process or technology requirements to be the motivation for thinking about expanding the applicability of existing solutions or even pursuing completely different and new approaches using our expertise. We are also happy to implement special know-how – for example from partners – in new plants. This results in plant concepts as well as plants in special and customized designs, which are available for application tests, among other things, up to complete special and customized plants on an industrial scale.

Production Plant for

Sodium Cyanide NaCN

Production of non-hazardous NaCN briquettes from hydrocyanic acid with a technology license from DuPont, Wilmington, USA

Fluidized Bed System

made of Glass

Glass version for all parts in contact with the product for processing special materials with the highest demands on the degree of cleanliness

High Temperature

Fluidized Bed Systems

High temperature processing for simultaneous particle formulation and -functionalization at temperatures up to 900°C

Phosphate Fertilizer

from Sewage Sludge Ash

PHOS4green technology for phosphorus recovery from ashes with direct conversion into ready-to-use granules

Production of Cosmetic Pigments

Cooperation Merck & Glatt

Merck plant designed and engineered by Glatt on the basis of chemical vapor deposition (CVD) at the Glatt Technology Center in Weimar, Germany

Further information on this topic and related topics can also be found in the following publications:

Published article: ‘Growing the German phosphate industry’. PDF, English

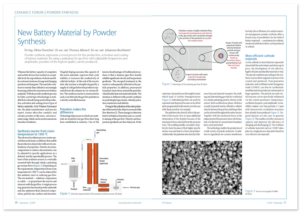

Published article: ‘New Battery Material by Powder Synthesis’ PDF, English

Published article: ‘Process Technologies to Optimize Detergent Manufacturing’ PDF, English

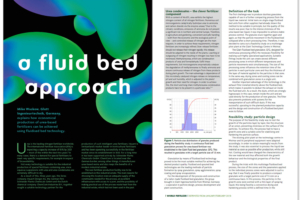

Published article: ‘A Fluid Bed Approach – Case study on the economical production of urea-based fertilizers can be achieved using fluidised bed technology’ PDF, English