Continuous operation of all fluid bed processes and their combinations.

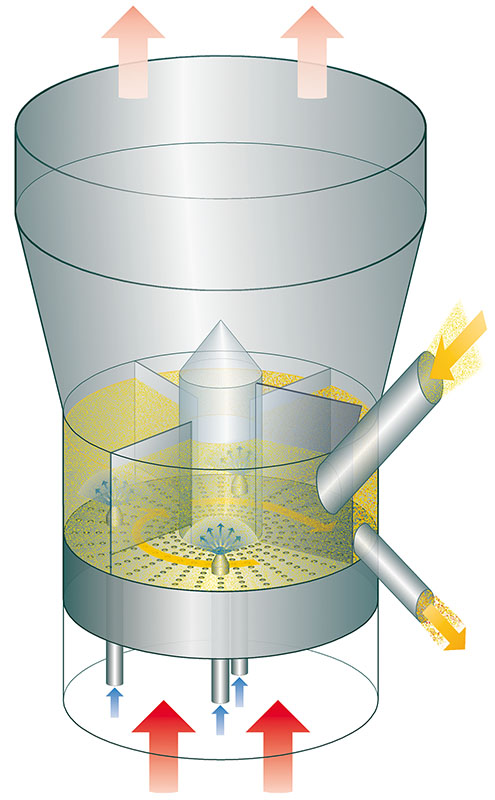

Whether spray granulation or encapsulation of liquids, agglomeration of powders or coating of particles – the plug flow through the process chambers allows the combination of the processes as well as the following drying and cooling. The way you need it.

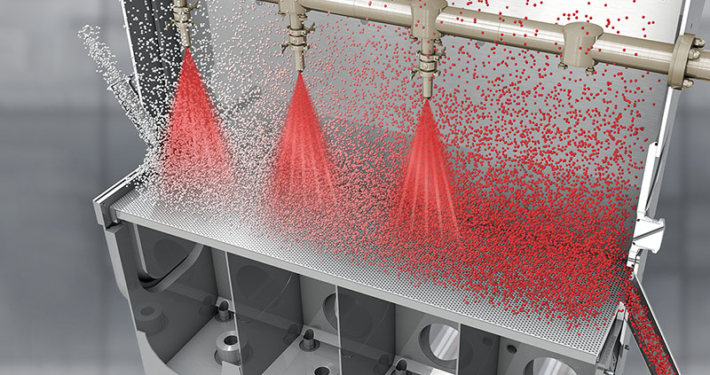

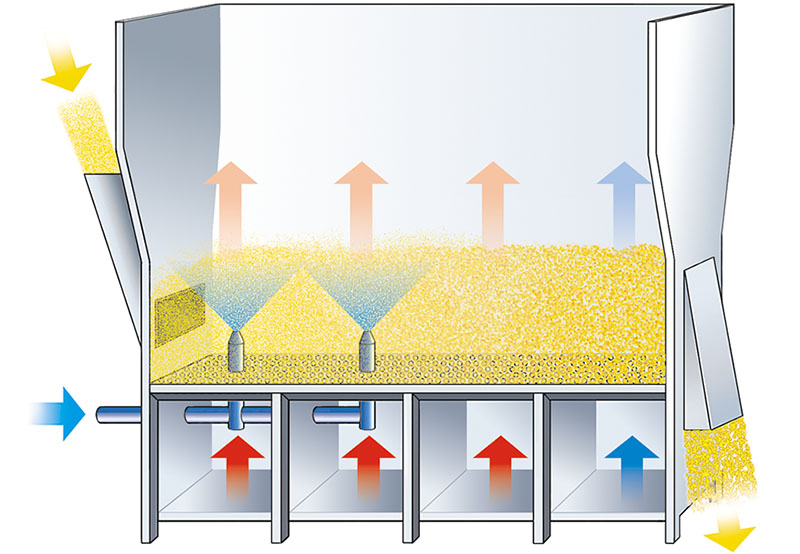

Glatt fluidized bed granulators GFG with elongated, rectangular fluidized bed enable targeted material movement through the process chamber. This can be divided into zones if required. This makes it possible to introduce process air into the process at different flow rates and different temperatures.

Due to this flexibility and the different arrangement of the nozzles in the process chamber, completely different conditions can be set in different zones of the process chamber. This allows the particles to be selectively exposed to different process conditions one after the other, enabling multiple process steps in the same system – e.g. granulation, drying and cooling. And all this with continuous operation.

Process flexibility thanks to the flexible design

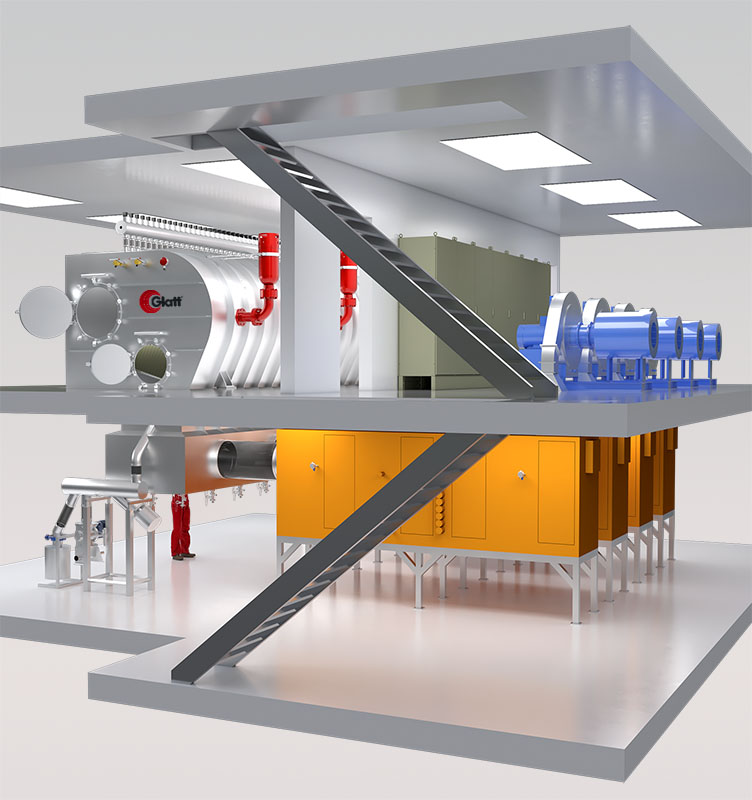

In order to make maximum use of the process technology flexibility of the plants, Glatt has also placed great emphasis on flexibility in the design.

The standard plant consists of the following assemblies: process chamber, internal filter, feed, discharge and spray system. These assemblies can be adapted independently of one another to meet the respective requirements. If required, the filter is replaced by a cover and installed externally. The installation of the nozzles can be designed in such a way that their arrangement can be changed even after the plant has been commissioned. This allows the plant to be quickly and easily adapted to new process requirements and product properties.

Depending on the quality requirements of the end product, Glatt offers two versions:

Chemical standard

- for mono-production plants or plants where product changeover is possible without hygiene requirements

- simple design

- high supply air temperature for high throughput

Food standard

- for plants with high cleaning requirements, for frequent product changes and increased hygiene requirements

- high surface quality of all wetted parts

- low supply air temperatures for temperature sensitive materials

Glatt’s range of products and services for fluid bed plants of the GF seires includes both the design according to the application in the chemical, food, feed or pharmaceutical industries, and the peripheral equipment such as process air conditioning, dust removal, explosion protection, WIP/CIP systems, raw material supply or product handling.