Glatt Colloquium on Powder Technology

Discover interesting possibilities for the synthesis and functionalization of advanced powder particles!

What to expect?

You will get a comprehensive overview of processes for thermal powder production:

- Particle/process gas interaction

- Production of raw materials and precursors

- Processes in the synthesis reactor

- Downstream processes

- Analytics

- Application examples

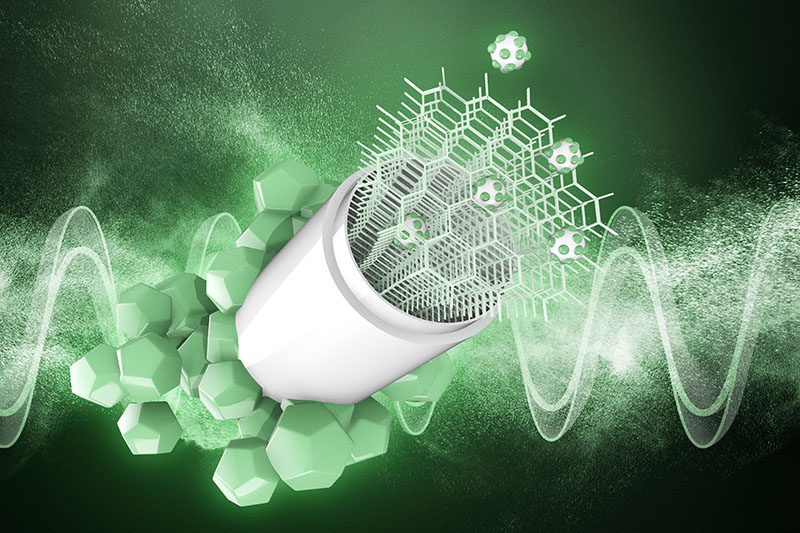

For synthesis, coating and calcination of micro- and and nanopowders, treatment in a pulsating hot gas pulsating hot gas flow has proven to be advantageous in numerous cases. Learn more about this technology and its potential.

We have succeeded in bringing together leading scientists in this field. In this way, we can shed light on the entire process chain in the production of novel powders, both theoretically and by means of selected examples.

Who should attend?

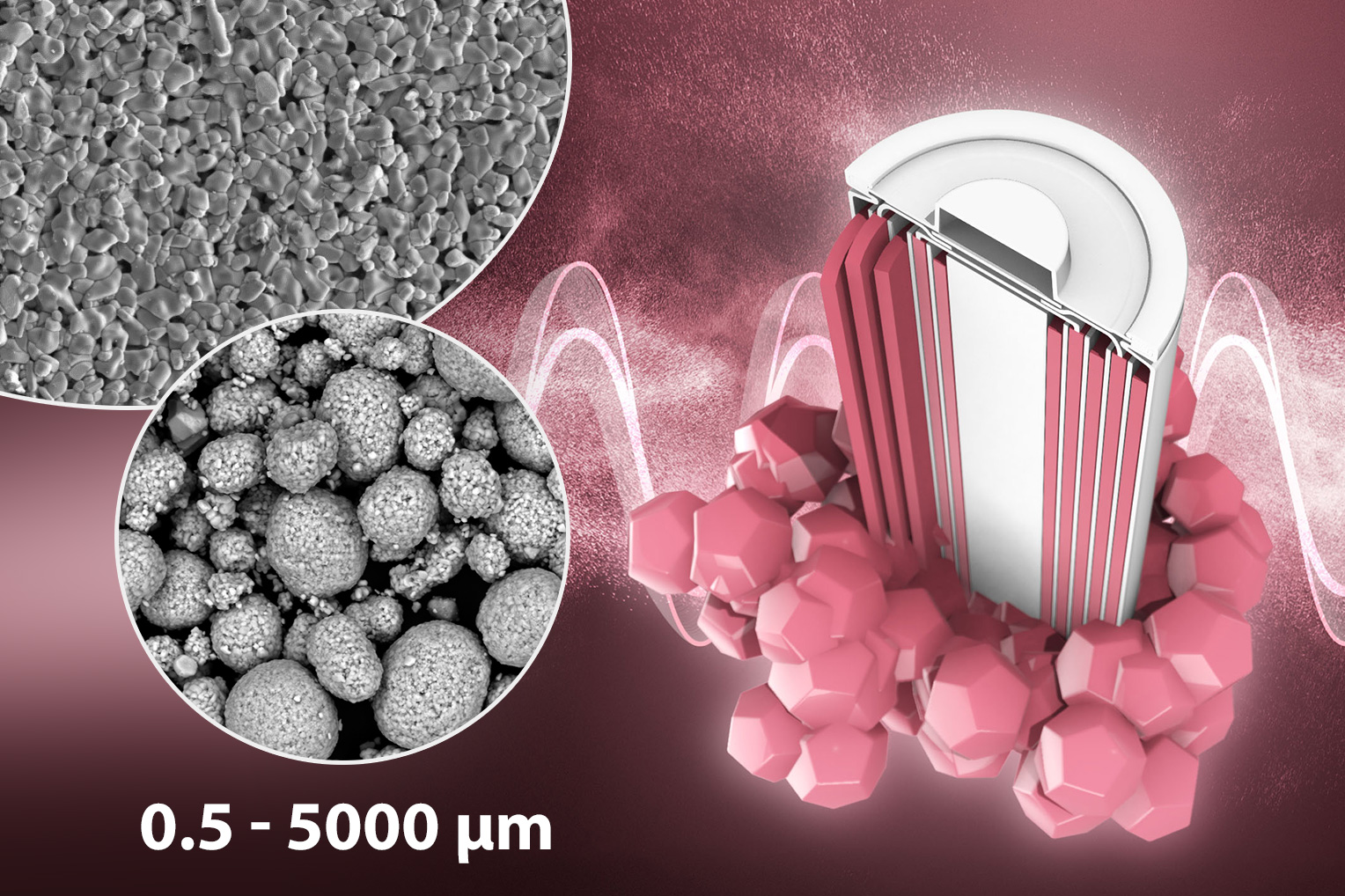

Are you a materials scientist, product developer and are you involved in research or production? The colloquium is basically aimed at anyone who is looking for novel ways to manufacture, coat and thermally post-treat fine powders – from the nano to the micrometer range.

Solutions for complex stoichiometry and crystal structure requirements, for example in mixed oxides, will be considered, as well as options for organic and inorganic core-shell coating and aspects of calcination.

The combination of theoretical considerations and practical experience takes into account different levels of prior knowledge.

How to participate?

Date

October 29-30, 2024

Location

Glatt Engineering GmbH, Nordstraße 12, 99427 Weimar

Participation fee

120 € (plus VAT)

Costs for the evening program on 29.10.2024 are included

Registration

Please register bindingly

Upon request, you will also receive recommendations for overnight accommodation in the cultural city of Weimar.

We welcome you here in Weimar!

Product Design of Battery Materials for More Capacity and Stability

- anode materials.

- cathode materials.

- solid electrolytes.

Reduce Material Use in Catalytically Active Powders

- High specifical surfaces.

- Smallest amounts of doping elements homogeneously distributed in the distributed in the product.

Ceramic Powders for Highest Demands

- Improve sintering properties.

- Increase strength.

- Increase catalytic effect.

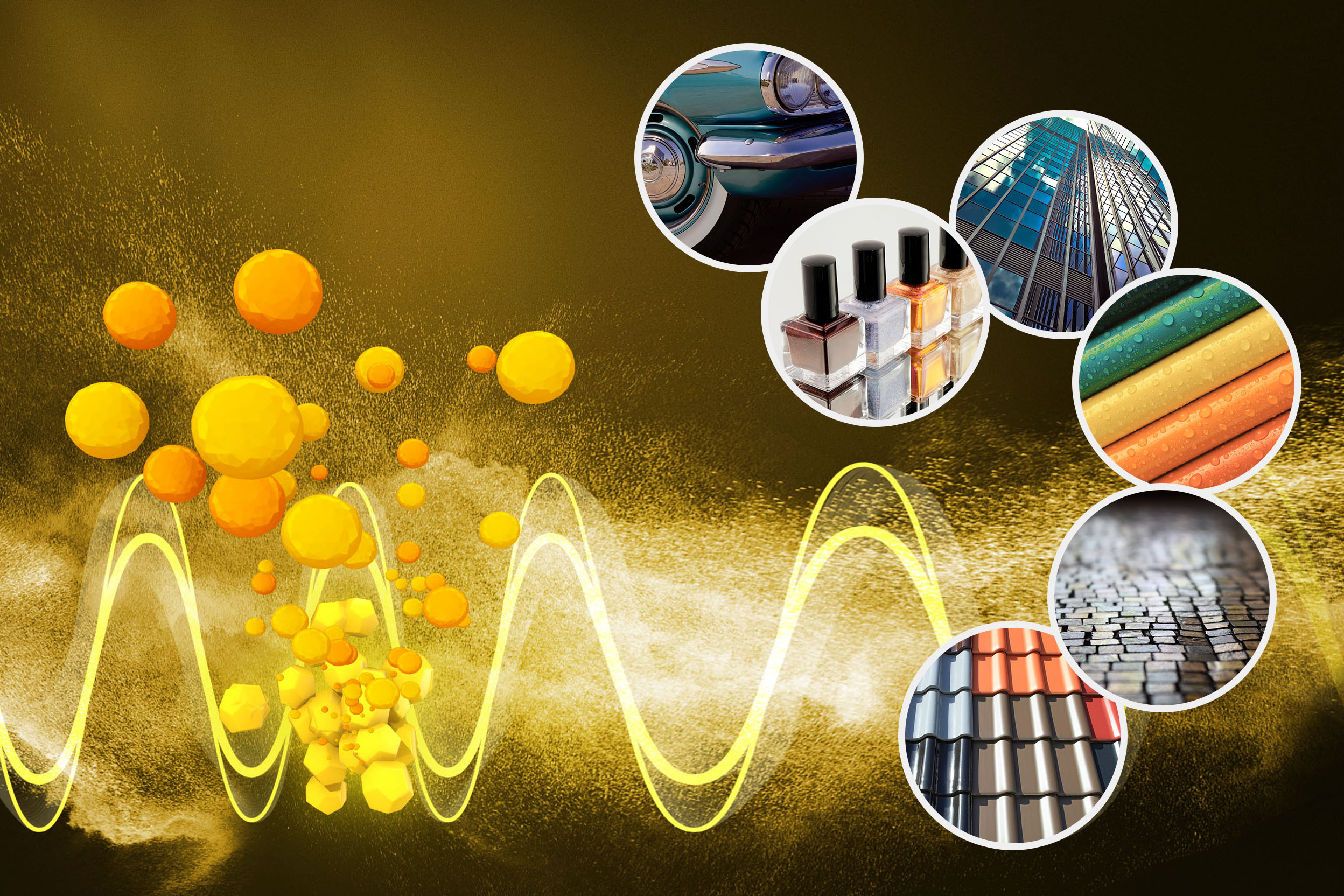

New Optical Effects and Maximum Protection for Paint and Varnish Pigments

- UV protection.

- Luminescent effects.

- Self-cleaning or antimicrobial action.

- Reflection of infrared light.

- Insulating or heat-conducting properties.