Obtaining xylan and ethanolic extraction to add value by recovering lignin and pulp

In the “XyloSolv” project, a process for the sequential extraction of beech wood with water and ethanol/water mixtures is to be developed and scaled up, making it possible to recover xylan, lignin and pulp as high-purity fractions. A hydrothermal process developed by HV-Polysaccharides and already tested on a laboratory scale enables the recovery of xylan in a previously unavailable quality through special process control, which is suitable as a base material for active pharmaceutical ingredients. However, since only about 10% of the beech wood is used in the current process, considerable amounts of aqueous extracted residue are produced as a waste stream.

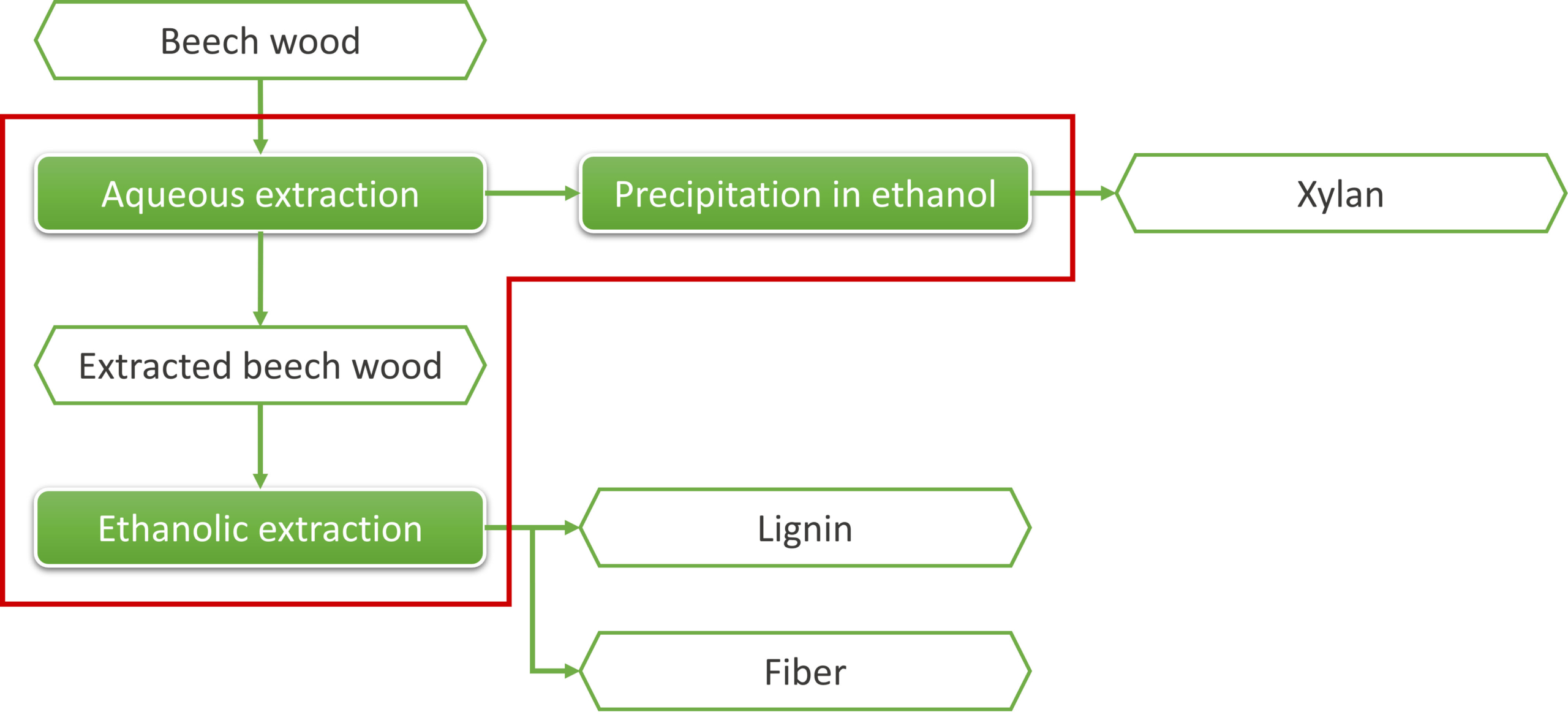

Figure 1: Process diagram of xylan extraction with coupled residue utilization.

The solution approach pursued in this project involves ethanolic extraction downstream of xylan extraction for additional value creation through the extraction of lignin and pulp (see Figure 1). This approach makes it possible to set up a plant that can already operate economically on a relatively small scale, thus implementing the approach of a beechwood-based biorefinery on an industrial scale for the first time.

The project relates to the objectives of the “Förderprogramm Nachwachsende Rohstoffe” and pursues in particular:

- the development of new technologies and integrated utilization concepts along the entire value chain, e.g. within the framework of biorefinery concepts,

- the improvement of the competitiveness of the domestic economy, especially in rural areas, through new and/or improved processes and products, and

- the sustainable production of industrial and consumer goods.

It addresses the funding areas “raw material and residue preparation and processing” and “biobased products and bioenergy sources”.

In the work package handled by Glatt Ingenieurtechnik GmbH, the aim is to evaluate the process specifications worked out for the pilot scale, taking into account all the influencing factors relevant to the overall process with regard to scalability to production-relevant plant scales. The basis is a comprehensive balancing of the material and energy flows in order to be able to derive basic design rules and a plant concept. This should not only enable consistent product qualities at t throughputs, but also be characterized by loss-free recycling of the auxiliary materials (ethanol, etc.) and an optimum energy balance. Only under these conditions is the transfer of the “XyloSolv” technology into a manufacturing process that can be operated economically a given, which is to be confirmed in the course of the techno-economic evaluations.

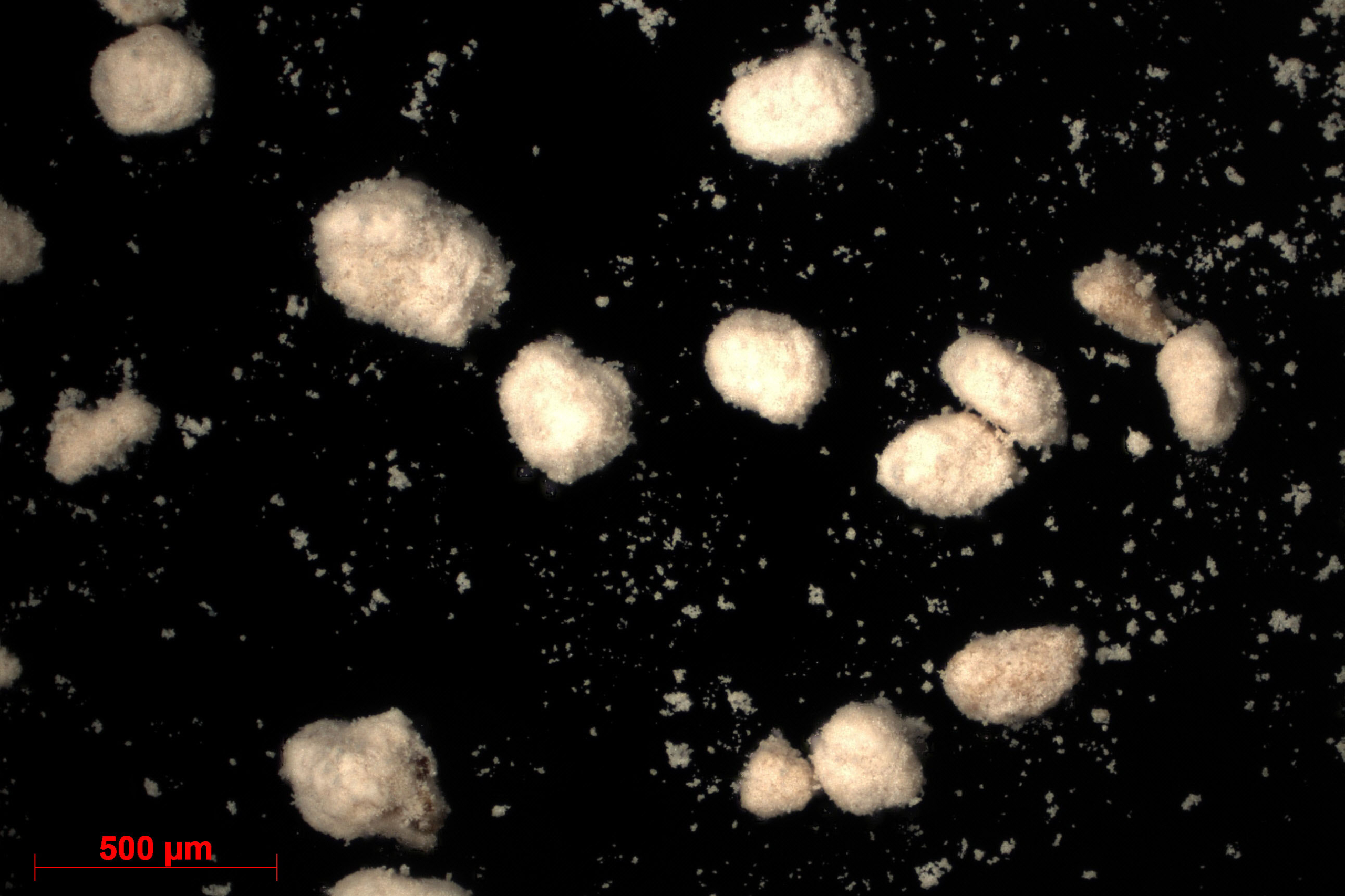

microscope image of high-purity, dried xylan granules

Project partners:

- Fraunhofer CBP

- HV-Polysaccharides GmbH & Co. KG

- Glatt Ingenieurtechnik GmbH

The project “XyloSolv” was funded by the German Federal Ministry of Food and Agriculture BMEL within the funding program “Renewable Resources”.

Funding period: 01.08.2019 – 31.12.2021

Glatt funding reference: 2219NR175

Further information on this topic and related topics can also be found in the following publications:

Published article: ‘Growing the German phosphate industry’. PDF, English

June 2021: Glatt Ingenieurtechnik honored as an outstanding company with the East German Business Forum Award

March 2021: Glatt Ingenieurtechnik celebrates continued business success with third expansion of its Technology Center

January 2019: Glatt Ingenieurtechnik GmbH is one of the 150 most innovative companies in Eastern Germany

Brochure A4: Glatt Technology Center Weimar, PDF, English