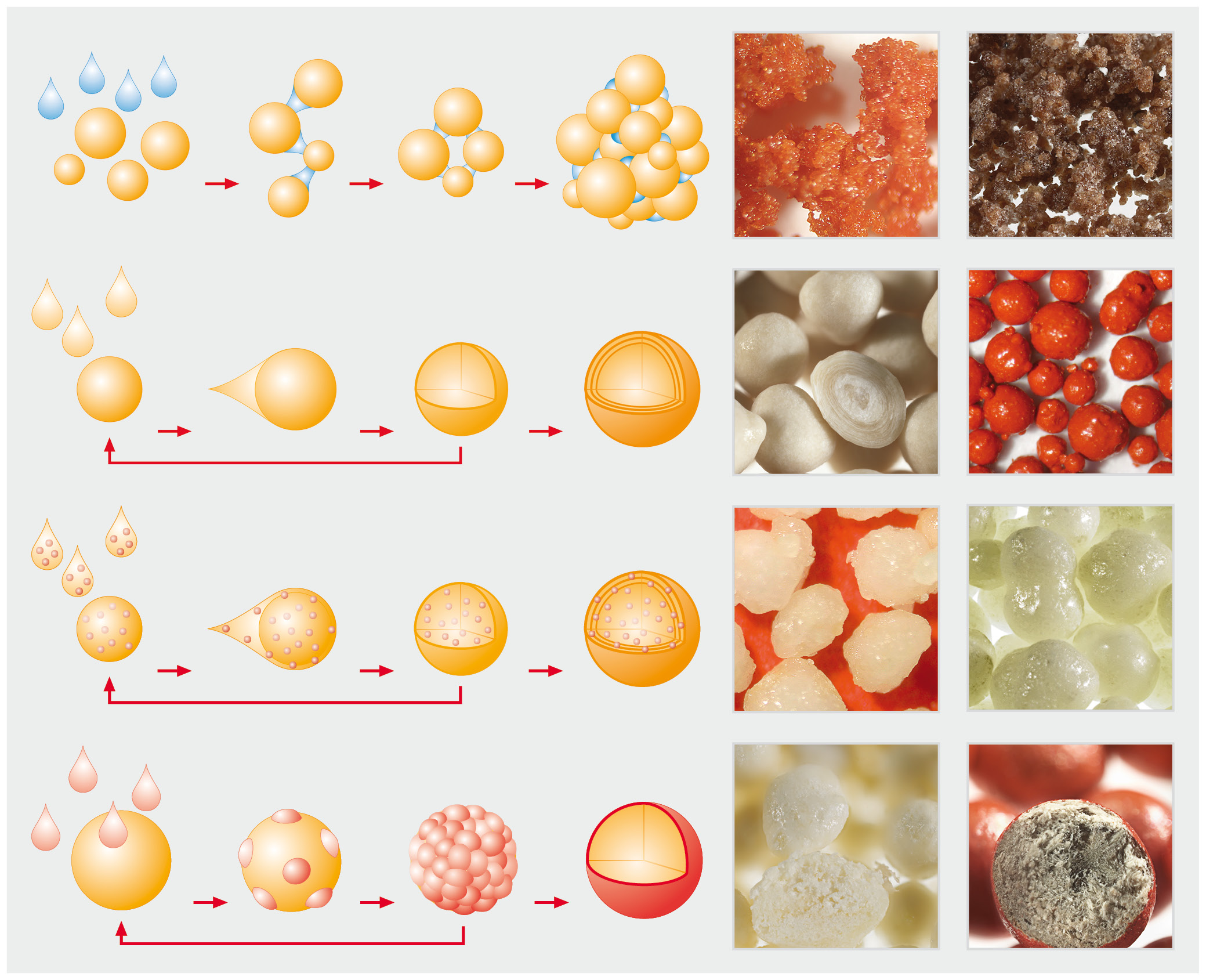

Glatt-Process-Product-Matrix. Functionalizing particles, granules and pellets by fluid bed and spouted bed technology

Make your particles functional for the best possible further processing and application.

Whether as beverage powder, detergent, fertilizer or catalyst – particles, granules or pellets are required to have a wide variety of functionalities, depending on their applications. In most cases, a free-flowing, dust-free product with adjusted particle size, bulk density and particle structure is expected. Powders for innovative and trendy food concepts must be stable in the long term, resistant to heat, cold, light and moisture. In the case of supplements or active ingredients, the targeted release of active ingredients and high bioavailability play an important role. The individual components of powder detergents must not react with each other during storage. Fertilizers should be released constantly over a long period of time or a catalyst should be activated or optimized.

Processing or treating products in Glatt’s fluid bed or spouted bed opens up virtually unlimited possibilities for optimum particle design. Both technologies enable the ideal functionalization of particles.

In spray granulation, a liquid containing solids is sprayed onto fluidized particles, triggering layer-by-layer particle growth. In this way, pellets with a homogeneous structure, dense surface, high abrasion resistance and excellent flowability can be produced.

If, for example, the product is sensitive to oxidation, micro-encapsulation can be used to embed the substance homogeneously in a protective matrix, thus protecting it against environmental influences and simplifying product handling.

If segregation or good dissolving behavior is a priority, spray agglomeration is a possible solution. In this process, a powder is sprayed with a liquid until the particles adhere sufficiently strongly to one another and form an agglomerate structure.

Covering particles with a defined layer also protects or functionalizes them. For example, by coating with an enteric substance, the release characteristics of active ingredients can be specifically adjusted.

Due to the intensive mixing and excellent heat transfer, the Glatt fluid bed is also ideally suited for drying or heat treatment of particulate systems. In this way, materials can be activated or made to react in a targeted and uniform manner by the hot gas flow in the fluid bed.

There is a wide variety of process variants based on fluid bed technology or spouted bed technology. At the Glatt Technology Center in Weimar, we work with you to determine the optimum process conditions for your product in feasibility trials for product development. Various laboratory facilities and comprehensive analytical equipment are available for this purpose. On our pilot plants, we optimize the process and scale it up reliably to a stable and economical production scale. The results from this form the basis for the design and construction as well as the erection of your fluid bed or spouted bed plant, tailored to your requirements. As an alternative to our own process technology, we offer you the outsourcing of your production by means of contract manufacturing at Glatt.

Further information on this topic and related topics can also be found in the following publications:

Published article: ‘Fluid bed and spouted bed technologies – Optimising functional ingredients for enhanced nutrition’ PDF, English

Published article: ‘Spray agglomerating plant-based milk alternatives for optimised product properties’ PDF, English

Published article: ‘Process Technologies to Optimize Detergent Manufacturing’. PDF, English

Published article: ‘Fluidized bed solutions for optimized ingredient production’ PDF, English

Published article: ‘Customised enzymes for optimal animal feed mixes’ PDF, English