Dry material processing – From the feasibility study to the production plant

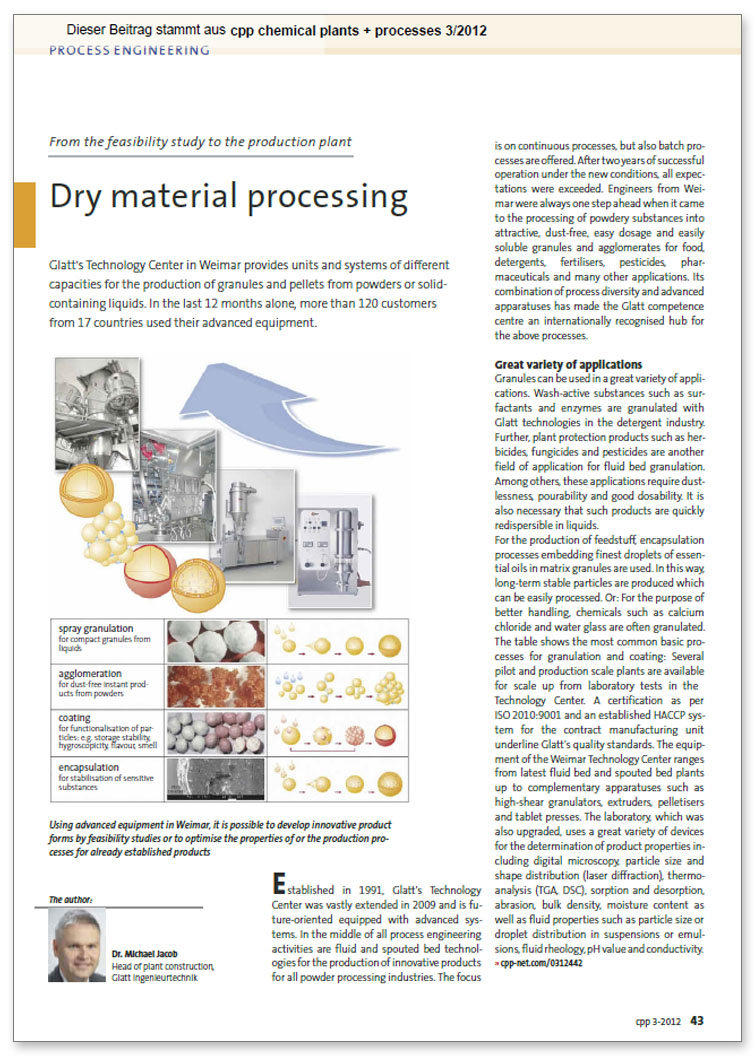

Glatt’s Technology Center in Weimar stands for innovative technologies for the production of granules and pellets from powders and/or solid-containing liquids. In the last 12 months alone, more than 120 customers from 17 countries used our advanced equipment to develop new product forms by feasibility studies or to optimize the properties of already established products for their production processes. Apparatuses and plants of different sizes are available for such studies – from a laboratory via a pilot up to a production scale.

- Author: Dr. Michael Jacob, Head of Process Technology Food, Feed & Fine Chemicals, Glatt Ingenieurtechnik GmbH

- originally published in the trade magazine ‘cpp – chemical plants & processes’, issue 06/2012, Konradin-Verlag Robert Kohlhammer GmbH and Dry material processing (process-technology-online.com)

Already established in 1991, the Weimar Technology Center was vastly extended and future-oriented equipped with advanced systems in 2009. After one year of successful operation under the new conditions, all expectations were exceeded.

At the heart of all process engineering activities are fluid bed and spouted bed technologies for the production of innovative products for all powder processing industries. The focus is on continuous processes, but also batch processes are offered. Engineers from Weimar were always one step ahead when it comes to the processing of powdery substances into attractive, dust-free, easy dosage and easily soluble granules and agglomerates for food, detergents, fertilizers, pesticides, pharmaceuticals and many other applications. Its combination from process diversity and advanced apparatuses has long since made the Glatt competence center to be an internationally recognized hub for the above processes and the schedule for application tests is booked up months in advance.

Granules can be used in a great variety of applications. Examples include wash-active substances such as surfactants and enzymes in the detergent industry, instant granules such as cocoa drink or baby food that immediately dissolve in contact with water or milk. A special application is the encapsulation of flavoring agents such as orange oil. Fine droplets of oil are embedded in sugar granules (maltodextrin). In this way, not only an easy dosage of the flavoring agent but also its protection against oxygen can be ensured. Thus, it can be stored over longer periods of time. Also sweeteners and preservatives such as phosphates and benzoates are granulated for better dosage.

Several pilot and production plants are available for scale up from laboratory tests. A certification as per ISO 2010:9001 and an established HACCP system for the contract manufacturing unit underline Glatt’s quality standards.

The equipment of Glatt’s Weimar Technology Center ranges from latest fluid bed and spouted bed plants up to complementary apparatuses such as high-shear granulators, extruders, pelletizers and tablet presses.

The laboratory, which was also upgraded, uses a great variety of devices for the determination of product properties including digital microscopy, particle size and shape distribution (laser diffraction), thermoanalysis (TGA, DSC), sorption and desorption, abrasion, bulk density, humidity as well as fluid properties such as particle size or droplet distribution in suspensions or emulsions, fluid rheology, pH value and conductance.

So, the potentials for the development of customer-specific and efficient solutions quickly turn out. The team working here is also a competent and guiding partner for diverse special-purpose applications of the available fluid and spouted bed processes. This highly qualified team is composed of engineers from diverse disciplines such as mechanical and thermic process engineering, bulk materials engineering, food technology, processing technology and biotechnology as well as experienced technicians.

Moreover, the Weimar technology site is networked with many renowned scientific institutions such as universities, colleges and research institutes at home and abroad. This is the basis for ongoing improvements. Glatt Ingenieurtechnik presently owns about 100 process and apparatus patents all over the world.

Also, the knowledge about the above processes is passed on in regular workshops. The next two-day event on the topic “Optimized Plant Engineering” will be held in September 2011. The workshop provides an overview on integral planning of production facilities.

As an engineering company with own innovative process technology, Glatt Ingenieurtechnik offers its customers a comprehensive performance portfolio, starting from laboratory trials via product and process development up to the delivery of complex systems or complete factories. Be it process development, basic engineering, the delivery of apparatuses or a turnkey project, a close cooperation with the customer is the basis for individual tailor-made solutions. These are in particular available for the base and fine material, detergent and fertilizer industry. Other main areas are food and biotechnology as well as animal nutrition and veterinary medicine.

The constant investment in research and development in the field of process engineering now puts us in a position to improve products which could not be processed or only possible with great difficulty a few years ago. In this way, Glatt offers its customers access to a comprehensive technology base. In turn, the close cooperation with customers gives process engineering specialists the possibility for a further improvement of Glatt technologies for the processing of future products. This cooperation is a great challenge, but also the recipe for success when it comes to the company’s future.

Glatt Ingenieurtechnik GmbH Weimar, celebrating its 20th anniversary this year, sees itself as a full-service provider a partner for its customers from project initiation, development, implementation, commissioning up to the process engineering and technical service in a cross-sector and competent manner.

Further information on this topic and related topics can also be found in the following publications:

Published article: ‘Outsourcing – Trust in competent partners’ PDF, English

January 2022: Glatt expands technology center with new laboratory plant for powder synthesis

September 2021: New fluid bed options for solvent-based processes and products

June 2021: Glatt Ingenieurtechnik honored as an outstanding company with the East German Business Forum Award

March 2021: Glatt Ingenieurtechnik celebrates continued business success with third expansion of its Technology Center

Copyright: Konradin-Verlag Robert Kohlhammer GmbH

Copyright: Konradin-Verlag Robert Kohlhammer GmbH Copyright: Hüthig GmbH

Copyright: Hüthig GmbH