Glatt fluid bed granulator AGT® 2700, continuous spray granulation, detergent components, Turkey

Efficient granulation drying with excellent mixing success

Our circular single-chamber production plants allow drying of liquid raw materials while simultaneously building up granulates in an optimally mixed fluidized bed with gentletreatment of temperature-sensitive materials. Direct granulation of highly viscous solutions, suspensions and melts is also possible.

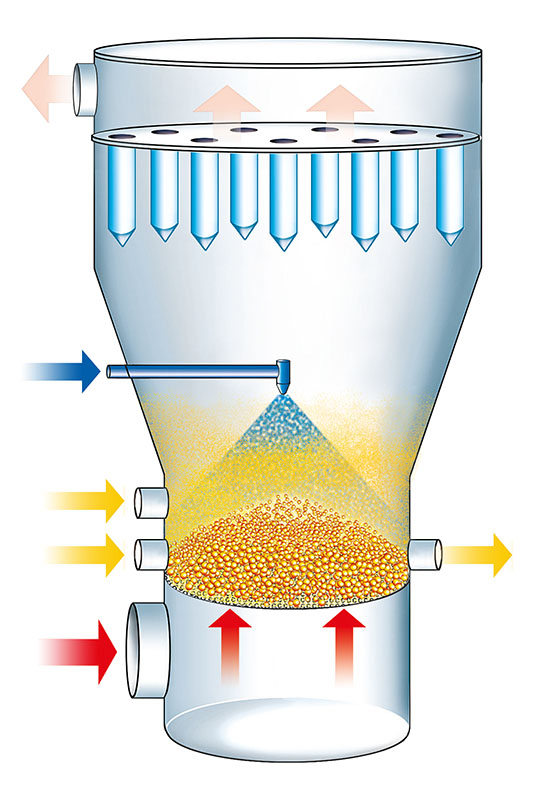

In a fluid bed system of the AGT® type (system for continuous granulation-drying), the entire fluid bed is constantly ideally mixed. The product can be discharged in the middle of the process chamber through a product discharge pipe. Here, the product particle size is determined by the flow velocity of the discharge air.

In most cases, a liquid raw material is dried with simultaneous granule buildup.

However, solid material can also be fed continuously. The mixing in the fluidized bed guarantees that the starting materials are present in the final product in a constant mixing ratio.

AGT® system for maximum process flexibility with interchangeable process chambers

Interchangeable process chambers for all fluid bed, spouted bed and rotor processes ensure maximum process flexibility. Whether spray granulation of liquids or agglomeration of powders, whether coating and powder layering of particles or encapsulation of liquids – everything is possible. In continuous or batch-controlled operation. Tailor-made for your process.

The variety of configurations includes different filter systems, various nozzle and spray systems, flexible solids feeders and granulate dischargers, through to classifying discharge for continuous operation.

For the combination of several process steps in one process chamber, there is the fluidized bed ring concept.

All options are available for fluid bed plants of the AGT® series from Glatt. This includes both the design according to the application in the chemical, food, feed or pharmaceutical industries, and the peripheral equipment such as process air conditioning, dust removal, explosion protection, WIP/CIP systems, raw material supply or product handling.

Glatt fluid bed system AGT® PilotSystem at the Weimar Technology Center

Principle of fluid bed technology in a Glatt AGT® type plant

Glatt fluid bed system AGT® System 1600

Glatt fluid bed granulator AGT® 250 for continuous spray granulation of iohexol, Norway

Glatt fluid bed granulator AGT® 1600, batch and continuous drying, spray granulation, spray agglomeration and coating, various food additives, Germany

Glatt fluid bed granulator AGT® 750, continuous spray granulation, phosphate fertilizer, PHOS4green, Germany

Glatt Fluid Bed Granulator AGT® 200, continuous and batch spray granulation, mineral fertilizer, Poland

Here you can find more photos: Installed plants.

Further information on this topic and related topics can also be found in the following publications:

Published article: ‘Growing the German phosphate industry’ PDF, English

Published article: ‘Contract manufacturing by fluid bed and spouted bed technology: Which is better, continuous or batch process?’ PDF, English

Published article: ‘Fluid bed systems: continuous, batch or a hybrid?’. PDF, German

Published article: ‘It’s all in the combination – Coating in the food and pharmaceutical industries, part 2’ PDF, German

Published article: ‘Integrated approach saves costs – Design and operation of energy-efficient fluid bed systems’ PDF, English