Meet us at the NIZO Conference in Papendal

Save the Date: October 14 – 17, 2025

Papendal Hotel and Congress Centre, The Netherlands

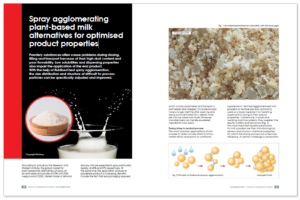

Glatt granulation and coating in the fluidized bed, continuous operation

Glatt spray agglomeration in the fluidized bed, top spray, batch operation

Check out the Glatt innovations in dairy ingredients

Join us at our poster presentation to discover how our fluid bed process can unlock new potential in probiotic dairy powders. We look forward to discussing ideas, insights, and opportunities with you!

The demand for functional dairy powders enriched with probiotics is steadily increasing – consumers are seeking products that offer real health benefits.

Under the heading Functional Probiotics in Dairy Powders by Innovative Fluid Bed Technology our latest development demonstrates how cutting-edge fluid bed technology can effectively protect, stabilize, and deliver probiotic cultures with precision.

Your key benefits:

✅ Preserved bioactivity

Gentle processing at controlled temperatures maintains the viability and effectiveness of sensitive probiotic microorganisms.

✅ Targeted release in the body

pH- and time-controlled coating with shellac ensures release exactly where it’s needed – in the gastrointestinal tract.

✅ Improved solubility & stability

Optimized powder structure through precise drying and coating on particles for better performance in application.

✅ Gentle processing

Fluid bed technology enables controlled drying with lower thermal stress – ideal for preserving the functionality of probiotics.

✅ High scalability for industrial applications

From lab scale to full production: our process is practical, scalable, and cost-efficient.

Who will benefit?

- Dairy product manufacturers focused on functional and value-added ingredients

- Health & Nutrition companies developing innovative wellness solutions

- Developers of next-generation probiotic supplements

Excellent solubility of collagen hydrolysate: Powders of the same raw material in comparison, produced once by means of spray agglomeration + spray granulation in a continuously operating multi-chamber fluidized bed system from Glatt and once by means of spray drying in a conventional spray tower.

Copyright: Konradin Mediengruppe

Copyright: Konradin Mediengruppe