Spray Granulation

Compact, dust-free granules from liquids containing solids.

Drying and shaping in one step.

The optimal solution for converting liquid substances into a solid product form

Fluid bed or spouted bed spray granulation is a process for obtaining flowable granules directly from liquids. It finds various applications in diverse industries, as the product properties can be varied in many ways by process engineering parameters and configurations. Due to their often round shape, the granules are also very suitable for subsequent coating.

Many industrial applications require the conversion of liquid substances into a stable product form with precisely defined properties – whether for further processing as solids in food, animal feed, cosmetics, detergents, fertilizers or crop protection products and numerous other applications. The granular form in all these applications is ideal for reducing product volume for transport and storage, for increasing stability in chemical substances, or for treating thermally sensitive products such as enzymes, proteins or microorganisms.

Spray granulation usually takes place in fluid bed systems or spouted bed systems in continuous operation.

Product properties of granules from spray granulation by fluid bed or spouted bed at a glance:

Dust free

Particles

Round

Pellets

Compact

Structure

High

Particle Density

High

Bulk Density

Low

Specific Surface Area

High

Particle Hardness

High

Abrasion Resistance

Adjustable

Particle Size

Defined

Particle Size Distribution

Very Good

Dosability

Excellent

Flow Behavior

Good

Solubility

Good

Dispersibility

Low

Hygroscopicity

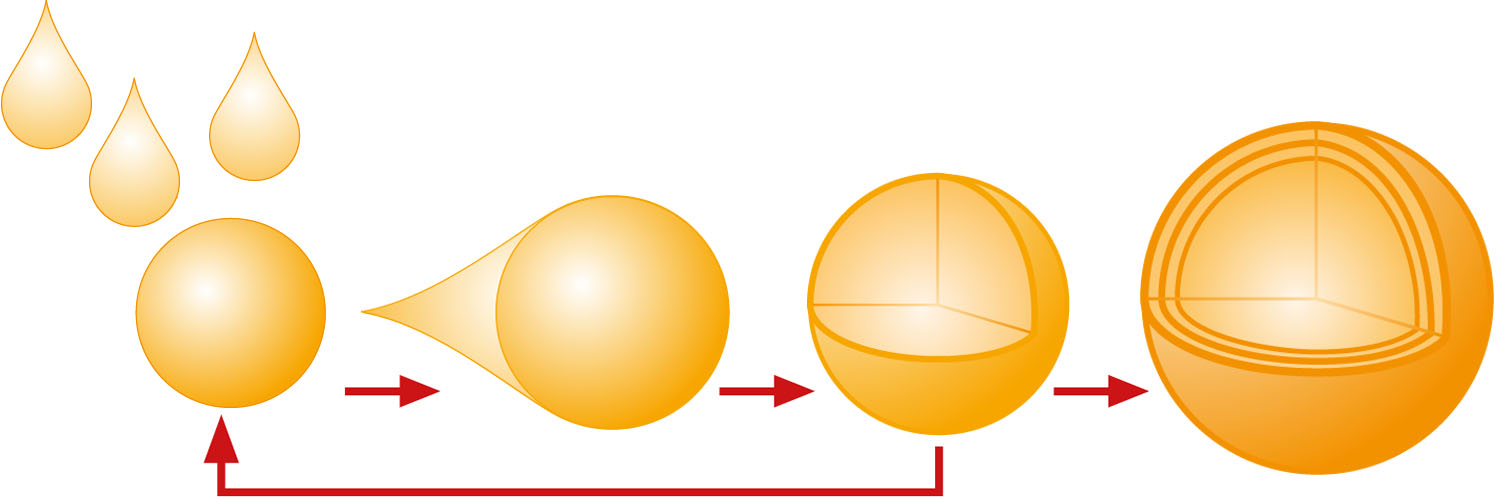

The process combines drying of liquids with simultaneous granule build-up. Liquids are sprayed onto fluidized particles and dry on their surface, initiating layer-by-layer particle growth. The small particles required to maintain granule build-up are generated in the process itself. Only the liquid raw material is required.

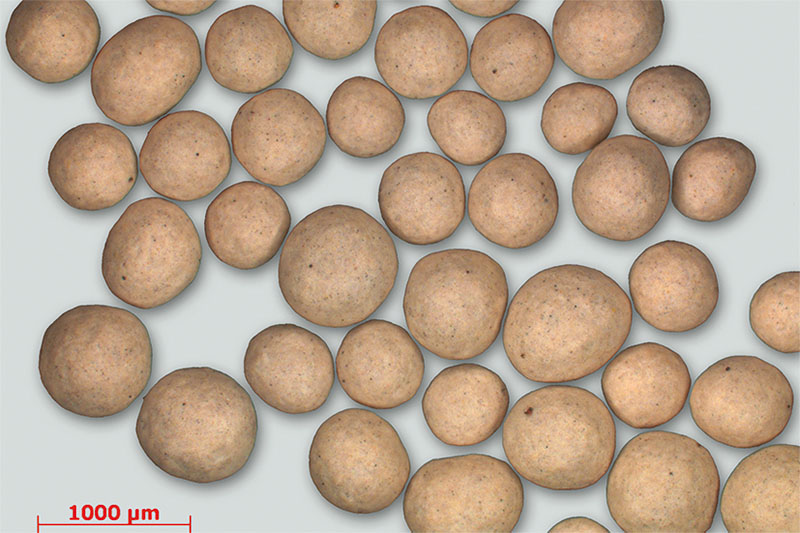

The spray granulation process can be used to produce granules with average particle sizes of 100 micrometers to 4 millimeters.

Spray granulation imparts desired properties to solids, such as flowability, abrasion resistance, good solubility or optimum dosability. The dust-free granules have a dense surface structure and high bulk density, and their reduced surface area makes them less hygroscopic. Parameters such as particle size, residual moisture and bulk density can be specifically influenced to achieve a wide variety of product properties.

Addition of solids

In addition, it is possible to add powdery or finely divided solids to the process in a targeted manner in order to incorporate them homogeneously into the granule structure or to use them as external starter cores for granule growth.

Protection of sensitive substances

Valuable substances that require special protection can be embedded in a protective matrix by means of micro-encapsulation and – homogeneously distributed – gently granulated.

Product examples

Lysine, spray granulated

Beta carotene, vitamin, spray granulated

Calcium chloride, detergent component, spray granulated

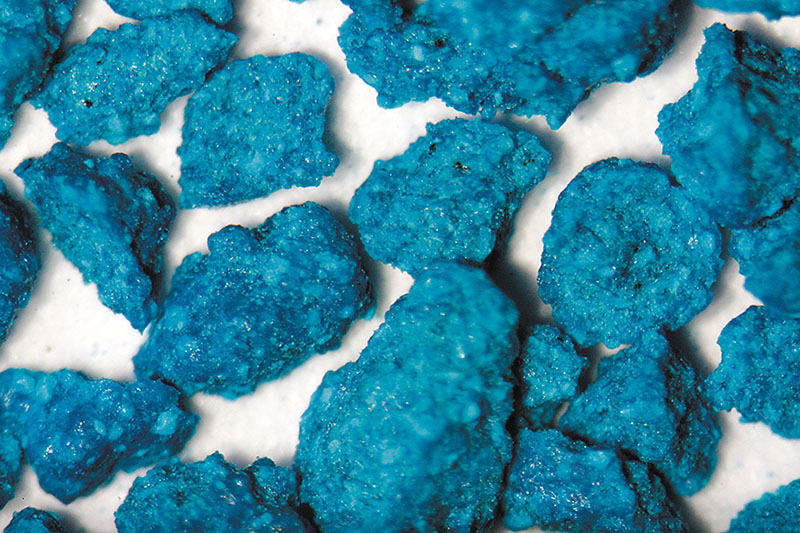

Copper hydroxide, fungicide, spray granulated

Ceramic, spray granulated

The spray granulation process in detail

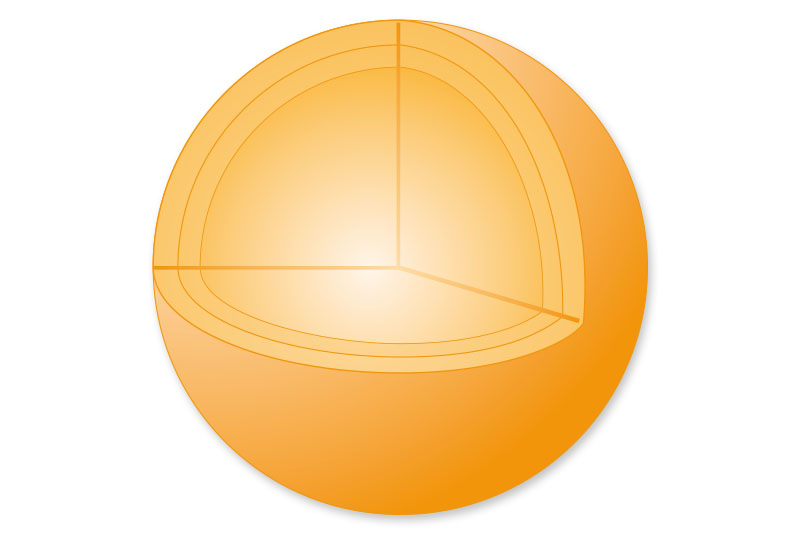

Liquids containing solids, such as solutions, suspensions or melts, are sprayed into a fluidized bed or spouted bed. Due to the high heat exchange, the aqueous or organic solvents evaporate or vaporize immediately, and the solids form small particles as carrier cores. These are wetted with further liquid, which in turn form a solid shell around the carrier core after drying. This process is repeated. The granules grow homogeneously in layers. No separate feed of raw materials is required. Alternatively, a defined quantity of suitable carrier cores can be supplied.

Drying of liquids and granulation by spray granulation

Glatt Continuous spray granulation in the fluid bed

Glatt Continuous spray granulation in the spouted bed

From the product idea to production

Since spray granulation processes start with the preparation of the liquid, we support our customers in developing the formulation and liquid preparation. The liquid can then be produced in a plant test at our technology center. Starting from laboratory scale, the product can be verified in pilot plants. Reliable scale-up enables the development of finished solutions on an industrial scale. Through contract manufacturing at Glatt, your new powders, pellets or granules can be manufactured, filled, packaged and delivered directly in agreed quantities. As a plant manufacturer, Glatt provides all services from project initiation, development and realization through to turnkey production in your own plant.