Agglomeration

Spray agglomeration, wet granulation or direct pelletizing of powders.

Dust-free granules with homogeneously distributed components.

Agglomeration processes convert powdery particles into free-flowing, low-dust, coarse granules with defined properties. Improved flowability or solubility, for example, facilitate further processing or direct handling, transport and storage of powdery substances and their mixtures. The granules reduce dust exposure and thus allergen exposure. For flammable substances, the ex-potential is minimized.

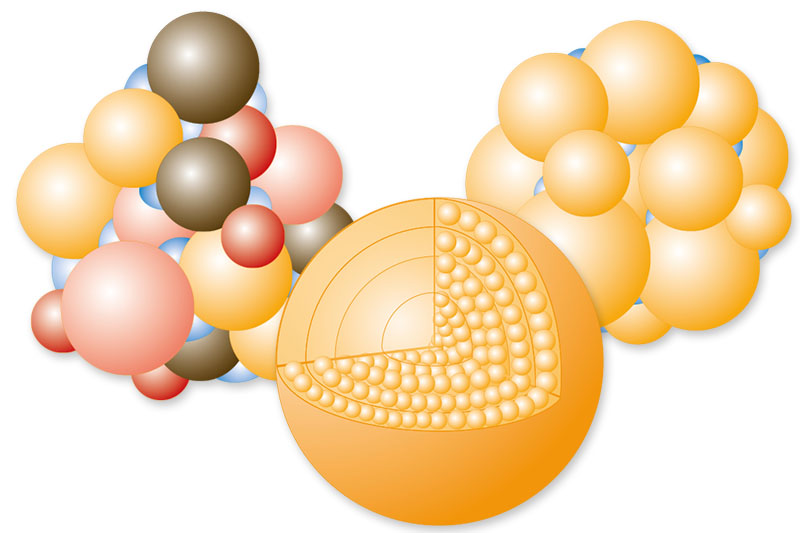

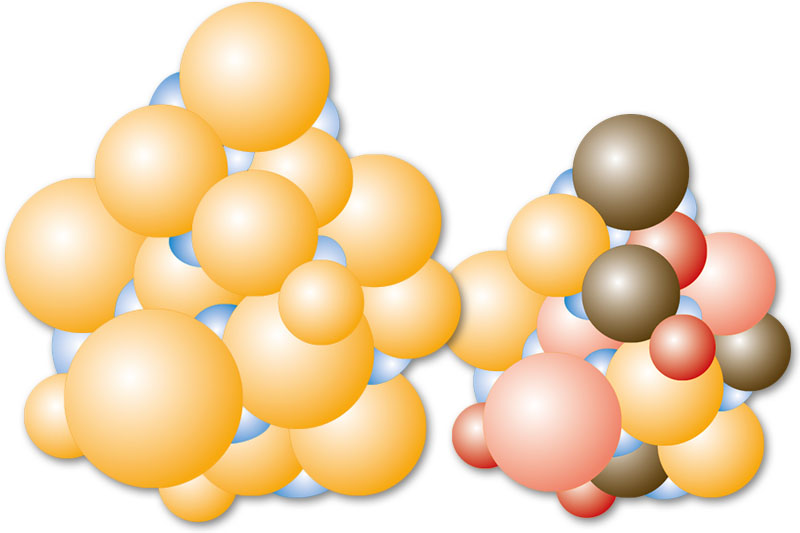

In agglomeration, finely dispersed primary particles are converted into cohesive units such as pellets or granules with a coarser particle size range by introducing a binder.

Spray Agglomeration

Porous, excellent soluble granules.

Homogeneously distributed components.

Ideal instant properties.

Wet Granulation

Dense, dust-free, compact granules.

Homogeneously distributed components.

Ideal extrusion properties.

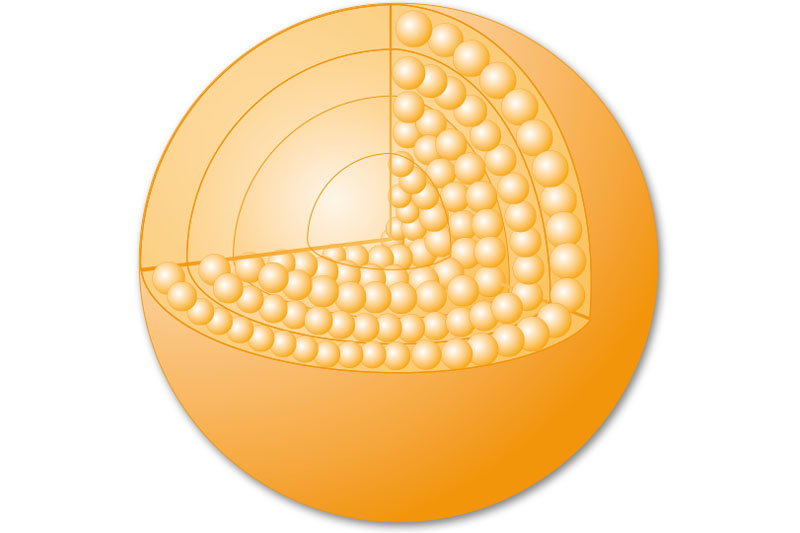

Direct Pelletizing

Spherical pellets with homogeneously distributed components.

Ideal shape for uniform coating.

High active ingredient content possible.

Further information on this topic can also be found in the following publications:

Published article: ‘Spray agglomerating plant-based milk alternatives for optimised product properties’ PDF, English

Published article: ‘Process Technologies to Optimize Detergent Manufacturing’ PDF, English

Published article: ‘Shaken or Stirred – Agglomeration with fluidized bed technology’ PDF, English

Brochure A4: Glatt Technology Center Weimar, PDF, English

Brochure A4: Glatt Functionalization of granules and pellets, PDF, English