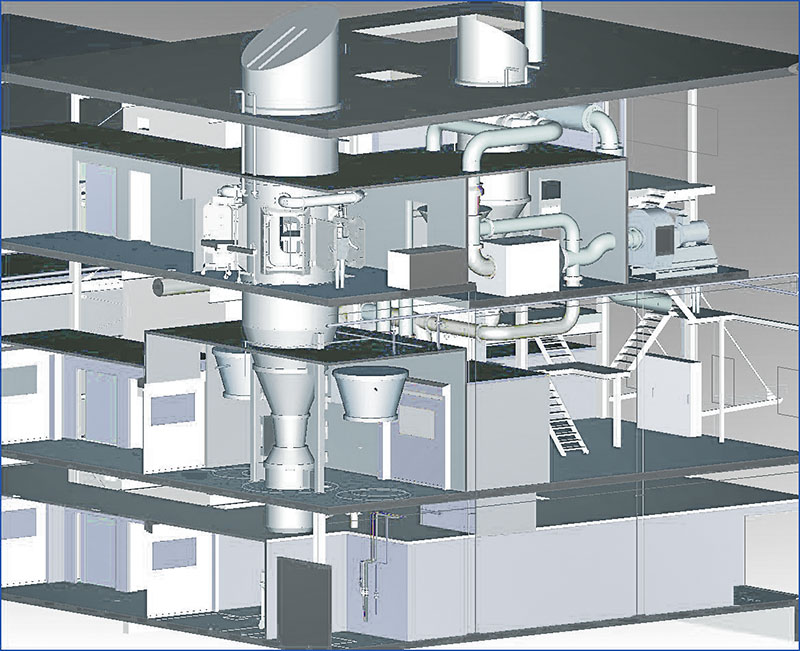

Glatt Engineering: 3D planning of the production facility including the Glatt fluid bed granulator GPCG 300 for batch spray agglomeration, coating, spray granulation and drying

New production facility for the contract manufacturing of pharmaceutical, food and feed ingredients at IPC Process Center, Germany, 2006/2007

Multipurpose batch fluid bed system with option for continuous spouted bed processes for Dresden-based contract manufacturer IPC

After commissioning the first batch fluid bed system in 2002, the next expansion was required in 2005. The process plant is again a GPCG 300 fluid bed particle coater-granulator, but with some additional details.

This GPCG 300 works with an enlarged filter and can be operated with increased process gas flow. This allows higher face velocities in the process. The larger filter area and a greater distance to the product bed extend the filter service life and significantly reduce downtime. The plant is equipped with a rotating or hinged bottom. This allows vertical product flow and reduces batch changeover times. This plant thus has the highest capacity and flexibility of the five batch fluid bed plants so far.

Three different process inserts allow different processes: Spray agglomeration with top spray nozzles, coating with the 32″ Wurster and coating with the 46″ Wurster.

In 2007, a ProCell® 70 process insert was also integrated into the GPCG 300 and a screen-grinding circuit was added to the line. This enabled IPC for the first time to offer direct conversion of liquids into granules with spray granulation processes. With the ProCell® systems, IPC has the latest process technology from Glatt – the innovative spouted bed.

The planning and execution of the plant, building and room equipment in pharmaceutical design were also completely in the hands of Glatt Ingenieurtechnik, Weimar.

The company IPC Process Center – based in Dresden, is a certified production facility for the contract manufacturing of refined products for the food, feed and fine chemical industries. Here, mainly modern fluidized bed processes are used, with specialization in granulation and coating.

Construction of a new production facility for the GMP-contract manufacturing of different granules and pellets at IPC Process Center

Project details:

| Location | Dresden, Germany |

| Schedule | 02/2006 – 12/2007 |

| Product | Various granules and pellets for pharmaceutical and food ingredients (e.g. enzymes and flavors) |

| Capacity | 300 – 500 kg/batch, depending on product and process |

| Building | New building, (facility 5) |

| Technology | Batch spray agglomeration, Wurster coating and drying in a Glatt fluid bed granulator GPCG 300 including a process insert ProCell® 70 for continuous spray granulation in the spouted bed |

| Scope of our services and supply | Turnkey project = turnkey project = product trials, feasibility study, process development, complete engineering including building, project management, delivery, construction site and assembly supervision, installation, commissioning/start-up, operator training, qualification/validation |

Glatt fluid bed granulator GPCG 300 with bottom discharge

material lock

pharmaceutical water treatment

cleanroom design

bottom discharge

manufacturuing GPCG 300

sieving station

accessible filter chamber

subsequent deduster

Published article: ‘Full Flexibility with Spouted-Bed – Glatt’s ProCell continuous spouted-bed equipment makes high-quality granulates and pellets’. PDF, English

Published article: ‘Outsourcing – Trust in competent partners’ PDF, English

Published article: ‘A spirit of optimism between batch and continuous production?’. PDF, German

Published article: ‘How to Tame Recalcitrant Ingredients with Technological Processes’ PDF, English

Published article: ‘Fluid bed and spouted bed technologies – Optimising functional ingredients for enhanced nutrition’ PDF, English