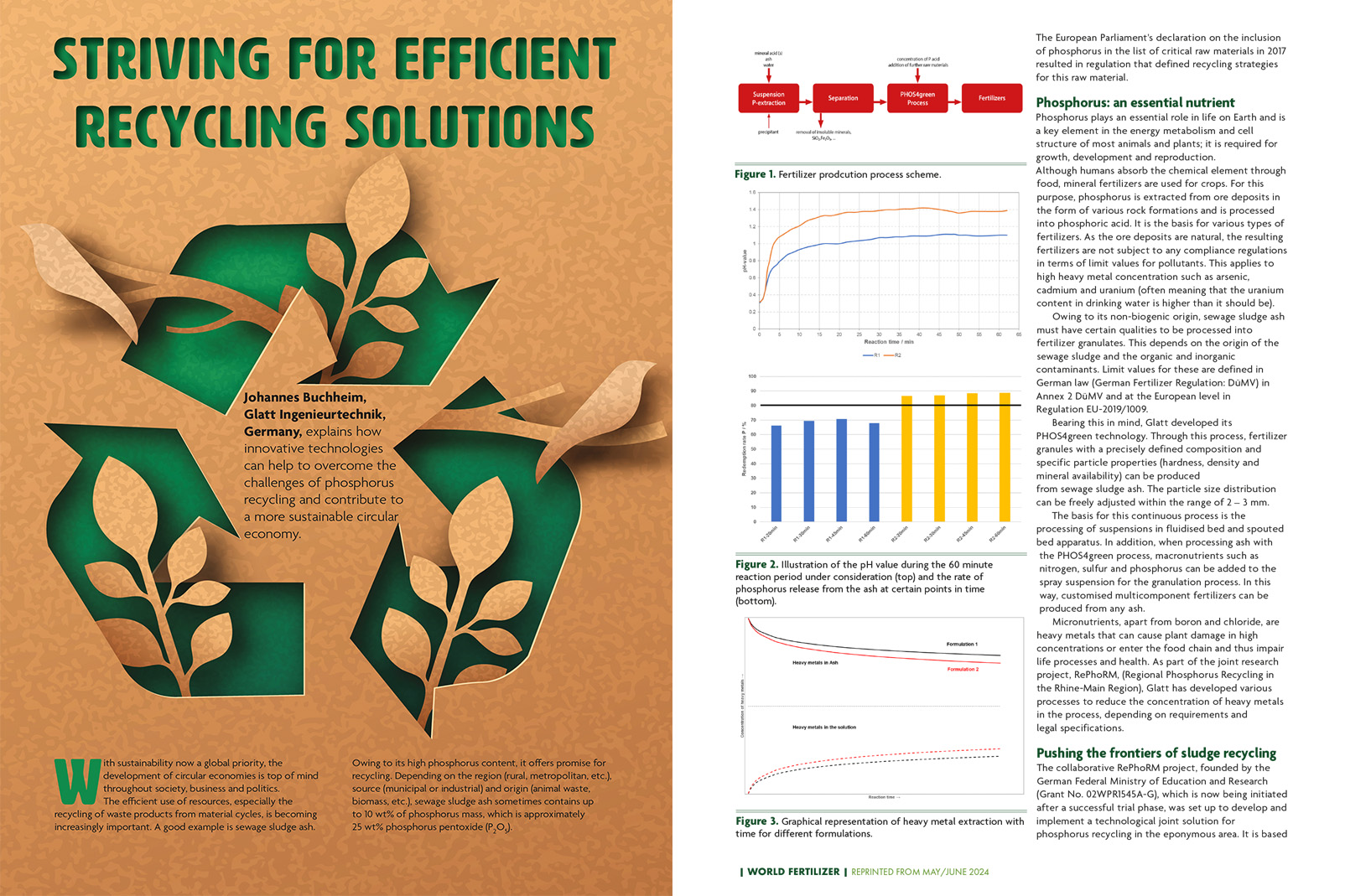

The extraction of the phosphate from the ashes is performed by a simple, flexible and stable process flow with well controllable reaction steps. Fluctuations in the composition of the sewage sludge ash are easily compensated by adjusting the recipe, which ensures a consistently high quality. The generated granules are dust-free, long-lasting and storage-stable, and have a compact, homogenous structure. They can be directly bagged, marketed and dosed as per a normal fertilizer. The solubility of these kind of granules is readily adjustable to the application. Furthermore, being dense, the abrasion-resistant surface reduces undesirable drift effects during application.

In addition, different compound fertilizers (such as NP, PK, NPK and NPS) can beproduced using the same procedure by adapting the recipe accordingly. The nutrients in each individual grain are distributed according to the specific application. Parameters such as particle size, residual moisture and solids content can be specifically influenced to achieve a wide range of product properties. PHOS4green sustainably closes the nutrient cycle and is an economical solution for fulfilling the legal obligation to recycle phosphorus. This procedure is 100 % wastefree – meaning that the ashes can be reused completely.

Additionally, the entire process is also waste-free. No harmful intermediate products or exhaust gases are produced during the process. The fertilizers produced in this way also contain up to 90 percent less cadmium and uranium than conventionally produced mineral fertilizers; the pollutant content is below the legal limits. At the Haldensleben site in Germany a project for an industrial-scale production plant is already being implemented for SERAPLANT GmbH. The location, the products to be manufactured and their recipes as well as the envisaged production capacities determine the economic efficiency.

Start of Production in Haldensleben is scheduled for the December 2020, after breaking ground in July 2019. The facility in Haldensleben has a capacity to produce 60,000 mt fertilizer and will start with the products P38 and NPS 12/27/8. About 35,000 mt sewage sludge ash will be recycled per year. The production for the product P38 is running fully automated, the process feed materials mineral acid and sludge ash are pumped infrom a silo, respectively. The installed silos hold a capacity for 5 days production, 24 h per day. For the product NPS the additives like sulphur are delivered in big bags and will be dumped in a station. The manufactured fertilizer will be dropped via conveyer from process building in a storage with capacity up to 16,000 mt. …

to read the full article

Content:

1. Hochleistungsdünger aus Klärschlammasche

2. Das patentierte Verfahren PHOS4green

2.1. Stufe 1: Aufschluss der Phosphatquelle

2.2. Stufe 2: Sprühgranulation in der Wirbelschicht

2.3. Optional: funktionelle Schutzschicht durch Wirbelschicht-Coating

3. Mehrnährstoffdünger aus angepassten Rezepturen

4. Ein zu 100 % abfallfreies Verfahren für zirkuläre Wertschöpfung

5. PHOS4green – Die Vorteile auf einen Blick

6. Ausblick

Copyright: LT Food Medien-Verlag GmbH

Copyright: LT Food Medien-Verlag GmbH Copyright: Deutscher Fachverlag

Copyright: Deutscher Fachverlag