A well-known solution for converting liquid substances into a solid product form.

The process of spray drying enables the recovery of fine-grained powders directly from liquids. The raw material to be dried is continuously sprayed into a hot gas stream. In a very short time – from fractions of a second to a few seconds – the liquid substance is dried to a fine powder.

Spray drying processes can be based on fluid bed technology and spouted bed technology as well as powder synthesis.

Powder production by means of spray drying has various applications in diverse industries, as the product properties can be varied in many ways by means of process engineering parameters and configurations. The powders produced in this way have a fine, open and porous structure. They often act as starting materials for subsequent spray agglomeration in the fluid bed or spouted bed. The powders can thus be optimized. Powder properties such as flowability, undersink behavior or dust tendency are improved.

Depending on the atomization principle (type and method of droplet generation, see FAQ) and the solids content of the liquid, primary particles (the smallest newly formed particles, see FAQ) between 5 and 200 µm are formed directly. The drying behavior of the liquid as well as the selected process temperatures determine the structure of the primary particles (powder). As a rule, homogeneous particles, hollow bodies and often transitional forms are formed.

In spray drying, depending on process control and fine particle recirculation (return of fine particles, see FAQ), intentional agglomeration effects can also occur. This also leads to a change in product properties.

Spray drying processes can be carried out in adapted fluidized or spouted bed systems or in synthesis reactors.

Product properties of powders from spray drying based on fluid bed, spouted bed or powder synthesis at a glance:

High

Porosity

Excellent

Solubility/Wettability

Low

Particle Density

High

Specific Surface Area

Adjustable

Particle Size

Adjustable

Composition

Product examples

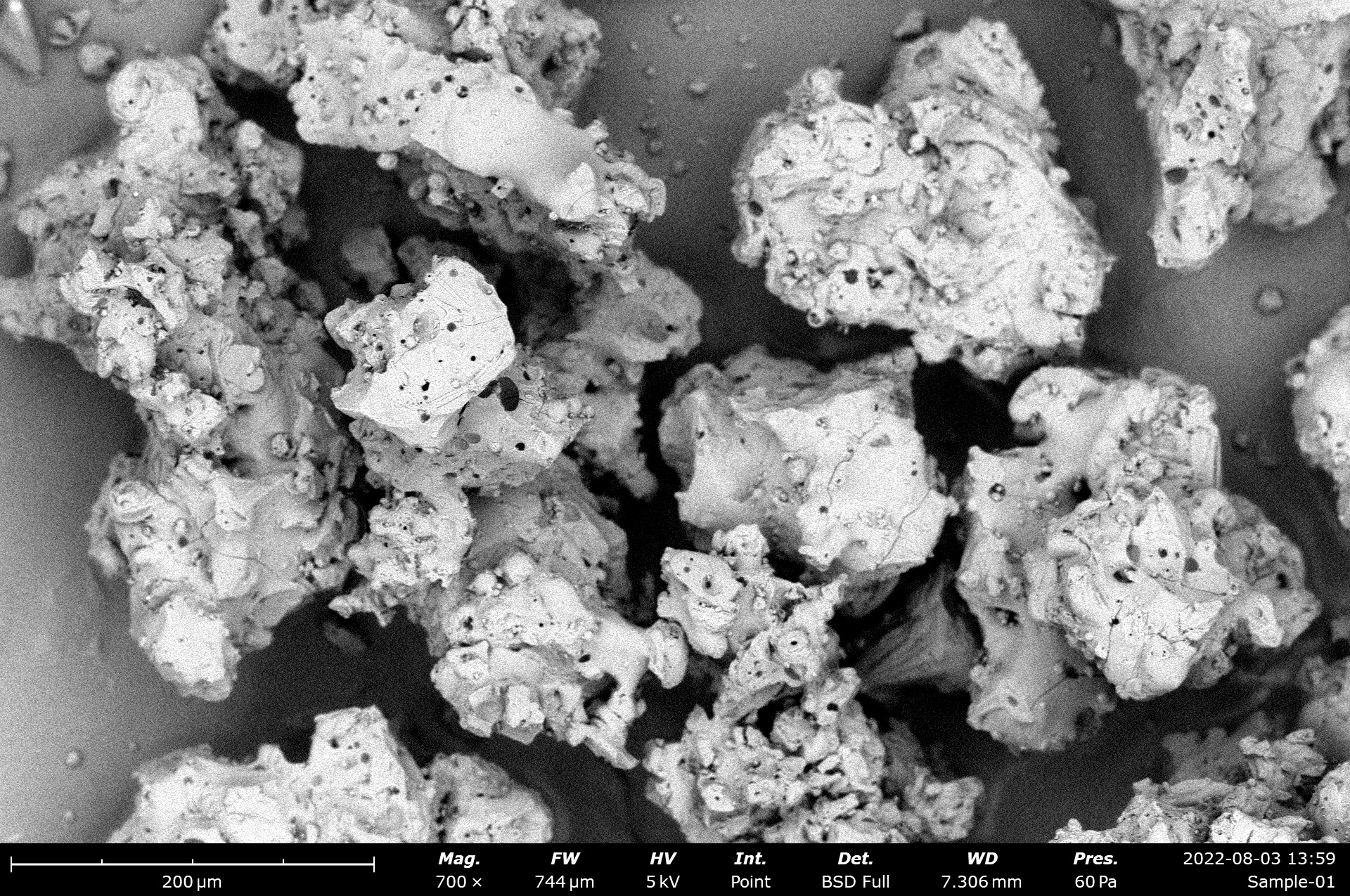

Carbon silicon anode material, spray drying, powder synthesis, SEM image

Protein product, spray dried by Glatt fluid bed technology, SEM image

Protein product, spray dried in a spray tower, SEM image

The process of spray drying in detail

Liquids containing solids, such as solutions, suspensions or melts, are sprayed into a fluid bed, spouted bed or into the pulsating gas stream of the Glatt powder synthesis. Due to the high heat exchange, the aqueous or organic solvents evaporate immediately. The solids directly form small particles. These powders form immediately by drying from the spray droplets. The powders are usually formed by convective drying, starting from the outer shell of the droplets. No separate feed of raw materials is required.

From the product idea to production

Since spray drying processes start with the preparation of the liquid, we support our customers in developing the formulation and liquid preparation. The liquid can then be produced in a plant test at our technology center. Starting from laboratory scale, the product can be verified in pilot plants. Reliable scale-up enables the development of finished solutions on an industrial scale. Through contract manufacturing at Glatt, your new powders, pellets or granules can be manufactured, filled, packaged and delivered directly in agreed quantities. As a plant manufacturer, Glatt provides all services from project initiation, development and realization through to turnkey production in your own plant

Watch the video on Excellent solubility of collagen hydrolysate!

Powders of the same raw material in comparison, produced once by means of spray agglomeration + spray granulation in a continuously operating multi-chamber fluidized bed system from Glatt and once by means of spray drying in a conventional spray tower.

Published article: ‘Drying liquids – Selecting the best technology for nutraceuticals’

The desired end product properties can make a difference when choosing between spray drying or spray granulation

Both spray drying and fluid bed spray granulation can be used to convert liquid products into bulk materials. The most effective process will often be dictated by the desired properties of the final particles and the specific application. Glatt Ingenieurtechnik has a thorough understanding of both techniques and has a long history of designing fluid bed systems that are tailored to individual customer products.

- author: Gudrun Ding, Head of Business Development Process Technology, Glatt Ingenieurtechnik GmbH, Weimar, Germany

- originally published in the magazine ‘Nutraceutical Business Review’, issue 05/2022, HPCi Media Limited

Improve the Solubility of Your Proteins

- Several processes.

- ONE process step only.

- Perfect solubility.

- Targeted control of product properties.

FAQ Spray Drying

What atomization principles are there?

The atomization principle in spray drying describes the process in which liquids are broken down into fine droplets in order to increase the surface area. This enables more efficient heat and mass transfer between the liquid and the hot drying gas. The droplets are formed by special devices called atomizers, which are considered the “heart” of the spray drying process.

There are different types of atomizers used in spray drying and they each work according to different principles.

There are basically nozzle atomizers and rotary atomizers. Nozzle atomizers are usually two-substance nozzles and more rarely pressure nozzles. In rotary atomizers, the liquid is fed into rotating internals where it is broken up into droplets by discs or rotors. Each type has its own advantages and disadvantages, depending on the type of liquid and the requirements of the end product.

What are primary particles?

Primary particles in spray drying are the smallest units of solid substance contained in the liquid suspension. During the spray drying process, these particles are exposed by the evaporation of the liquid carrier and form the basis for the structure of the end product. They can either be present individually or combine to form larger agglomerates, depending on the physical and chemical properties of the suspension and the process conditions.

The smallest newly formed particles in spray drying are often referred to as primary particles, i.e. a droplet becomes a primary particle (if droplet decomposition is neglected). These particles can then agglomerate with others in the spray dryer itself or be specifically recirculated into the injection zone in order to agglomerate there.

What is fine particle recirculation?

Fine particle recirculation is a process in spray drying that aims to improve the efficiency and quality of the end product.Fine particles that are produced during the drying process and would normally be removed from the dryer with the exhaust air flow are fed back into the drying process. This is usually done by special cyclones or filters that separate the fine particles and feed them back into the main dryer stream.

The benefits of this process include:

- Improved particle size: recirculation allows the fine particles to agglomerate with larger droplets or particles, resulting in a more uniform particle size.

- Increased product yield: Less material is lost as the fine particles are reused.

- Optimized product quality: Recirculation can help to improve the flow properties, density and other physical properties of the powder.

This process is often used in the food, pharmaceutical and chemical industries to produce high-quality powder products.

Further information on this topic and related topics can also be found in the following publications:

Published article: ‘Particles in an onion look – Drying of liquids by fluid bed spray granulation (vs. Spray drying)’ PDF, German

Published article: ‘Dried to the point – Thermal processes in the fluid bed’ PDF, German

Published article: ‘Glatt Powder Synthesis – Pioneering Process for Groundbreaking Particle Synthesis’ PDF, English

Published article: ‘Outsourcing – Trust in competent partners’ PDF, English

Published article: ‘Spray agglomerating plant-based milk alternatives for optimised product properties’ PDF, English