Our Technology Portfolio

Selecting the Most Suitable Technology According to Your Product Requirements!

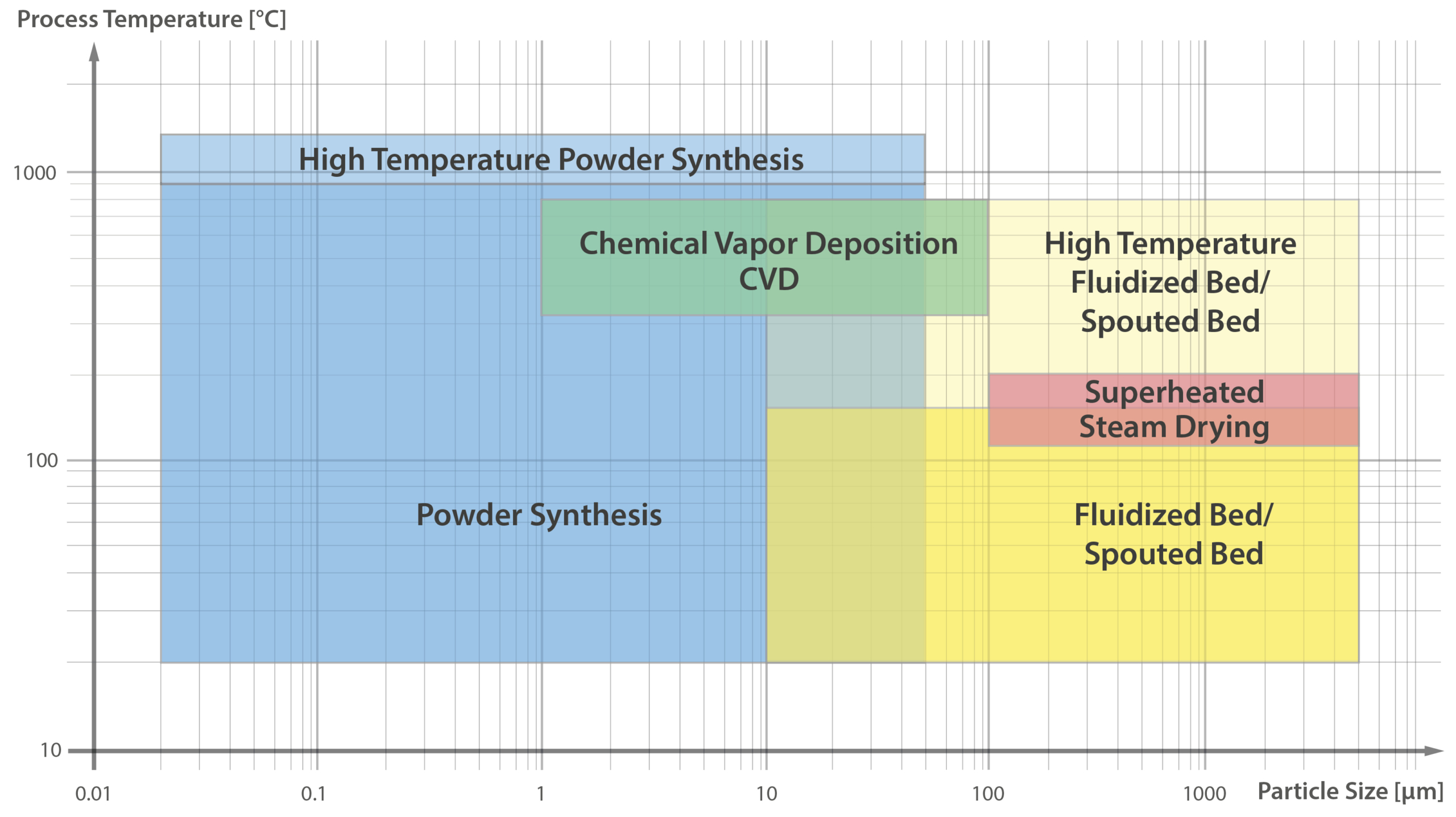

Whether production, modification or coating of powder particles in the nano and micrometer range or drying and spray granulation of liquids containing solids, spray agglomeration of powders, microencapsulation for the protection of sensitive substances or coating for particle functionalization – the key to the optimum product lies in the right selection of the substances and process parameters used and in the multitude of their combination possibilities.

In processes with innovative powder synthesis, fluid bed and spouted bed technologies from Glatt, you have almost unlimited possibilities for optimal particle design and suitable functionalization of powders, granules and pellets.

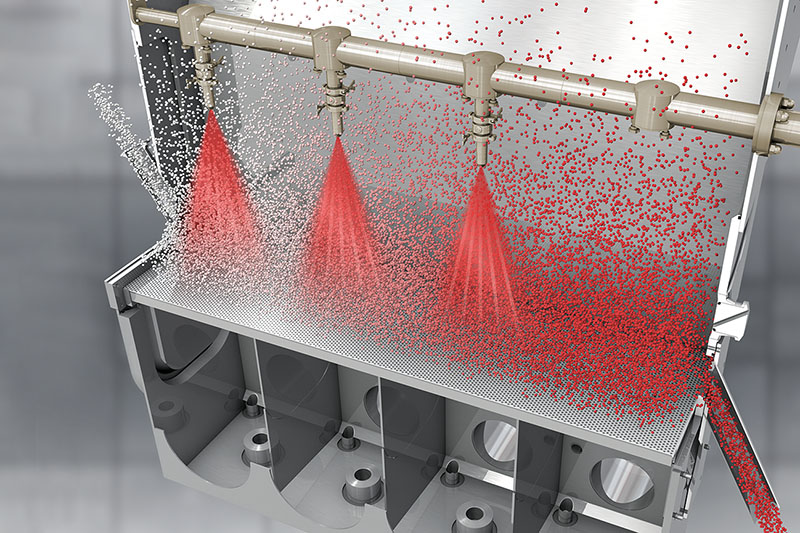

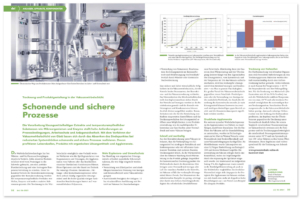

Fluid Bed Technology

Customized design of granules and pellets from solid and liquid raw materials

- Efficient process for gentle formulation of particle and bulk properties based on drying and coating

- Excellent heat and mass transfer and gentle treatment of temperature-sensitive materials

- Extended operating ranges for effective production of high-performance materials with special requirements

- Plant technology from the pioneer of fluid bed technology

Spouted Bed Technology

Individual design of temperature-sensitive, very fine and difficult to fluidize particles

- Efficient process for gentle formulation of particle and bulk properties based on drying and coating

- Patented apparatus geometry with modified inflow principle enables significantly higher heat and mass transfer rates

- Treatment of temperature-sensitive products with short residence times

- Processing of very fine materials, particles with very wide particle size distributions, irregular particle shape or surface structure as well as high stickiness

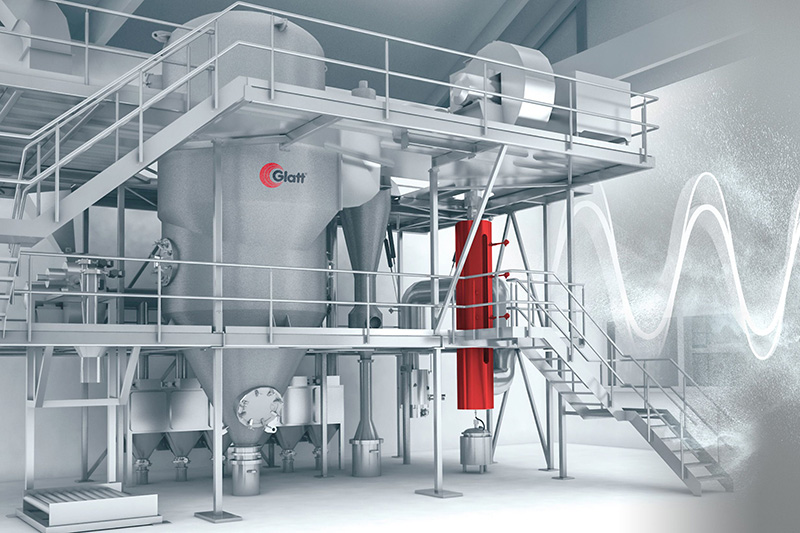

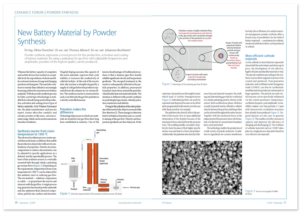

Powder Synthesis

Primary particle design in pulsating gas flow for your next generation of powder materials

- Precise design of novel powder types with precisely adjusted properties

- Production, modification or coating of powder particles in the nano and micrometer range

- Highest homogeneity and no hard aggregates

- Short residence times with significantly increased heat and mass transfer rates

- Particle formation, drying and calcination and in a single step

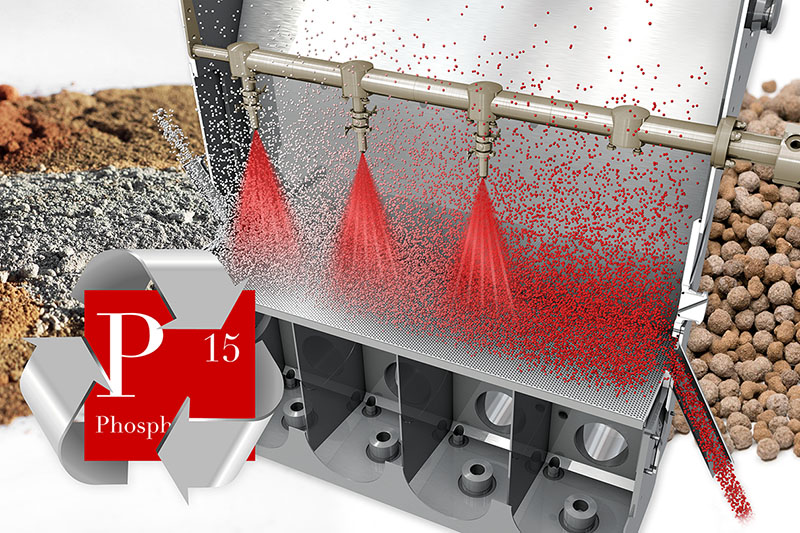

PHOS4green

Technology mix for the recovery of phosphorus from ashes with direct conversion into fertilizer granules

- Chemical reaction between ash and acid to break down the phosphorus

- Heavy metal depletion of the ashes

- Spray granulation of the defined ash suspension in the fluidized bed

- Production of ready-to-use standard and special fertilizers

- 100% waste-free utilization of the ashes

Further information on this topic and related topics can also be found in the following publications:

Glatt Technical Paper: ‘Growing the German phosphate industry’. PDF, English

Glatt Technical Paper: ‘New Battery Material by Powder Synthesis’. PDF, English

Glatt Technical Paper: ‘Glatt Powder Synthesis – Pioneering Process for Groundbreaking Particle Synthesis’. PDF, English

Glatt Technical Paper: ‘Gentle and safe processes – Drying and product design in the vacuum fluid bed’. PDF, German

March 2021: Glatt Ingenieurtechnik celebrates continued business success with third expansion of its Technology Center