Scalable, cost-effective manufacturing technologies for composite cathodes and electrolyte separators in solid-state batteries

Li-ion batteries with solid-state ion conductors and lithium metal anodes offer higher specific energy and are safer because the electrolytes are not flammable. Therefore, they are seen as a promising storage technology for future electric vehicles. Research activities in this area have increased significantly in recent years. The technical functionality of solid-state batteries can be demonstrated on a university laboratory scale. To date, however, there is a lack of process technologies for mass production.

The technical challenges of systems with sulfide ionic conductors (e.g., moisture sensitivity) and oxide ionic conductors (e.g., co-sinterability) are of a very different nature. The question of which of the competing approaches can achieve scalable manufacturing and be considered for electromobility remains unanswered.

The aim of the “ARTEMYS” project was to develop suitable process technologies for the manufacture of all-ceramic solid-state batteries, in particular the composite cathode and the solid electrolyte separator made of lithium lanthanum zirconium oxide (LLZO). These process technologies were evaluated with regard to their scalability and sample cells were built on laboratory scale. This provided both a performance-based and a cost-based decision-making basis for subsequent industrialization.

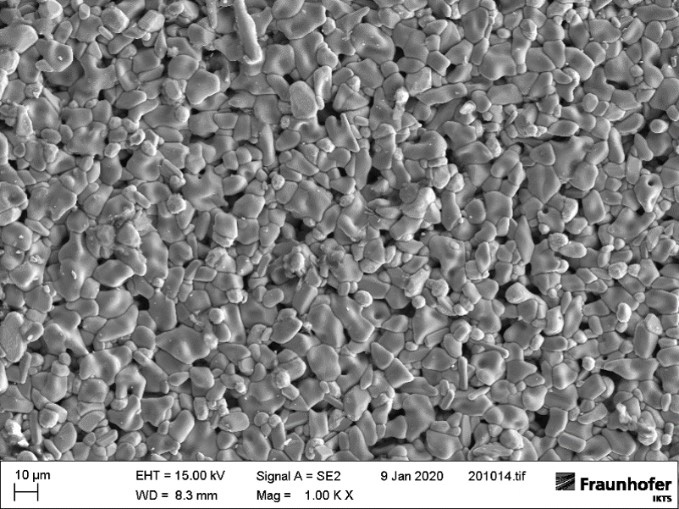

In this project for the development of new battery materials, Glatt Powder Synthesis proved to be a scalable and cost-efficient technology for the production of LLZO powder materials with the required electrochemical properties. The project succeeded in comprehensively identifying the factors influencing the powder qualities on the raw material side and overcoming the hurdles to scalability.

Finally, LLZO samples were produced which can be sintered into homogeneous and dense electrolyte layers and which meet the electrical performance specifications required by the project. The research project therefore provides a good basis for the medium-term commercialization of LLZO powders and solid-state electrolyte separators composed of them.

New battery materials by Powder Synthesis: sintered LLZO membrane, copyright: IKTS

Partners:

- BASF SE

- BMW AG

- Ferro GmbH

- Fraunhofer-Institut für Keramische Technologien und Systeme (IKTS)

- Glatt Ingenieurtechnik GmbH

- Karlsruher Institut für Technologie (KIT), BELLA – Batteries and Electrochemistry Laboratory

- Rehm Thermal Systems GmbH

- Robert Bosch GmbH

- thyssenkrupp System Engineering GmbH

- TRIDELTA Thermprozess GmbH

- Universität Bayreuth, Lehrstuhl für Funktionsmaterialien

The joint project “ARTEMYS” was funded by the German Federal Ministry of Education and Research (BMBF) on the basis of the framework program “From Material to Innovation” and the National Development Plan for Electromobility – Research and Development Projects on the topic of “Battery Materials for Future Electromobile, Stationary and Other Industry-Relevant Applications (Battery 2020)”.

Duration: 2017 – 2020

Funding code: 03XP0114E

Click here to go to the website of “ARTEMYS I Battery 2020”.

Further information on this topic and related topics can also be found in the following publications:

January 2022: Glatt expands technology center with new laboratory plant for powder synthesis

June 2021: Glatt Ingenieurtechnik honored as an outstanding company with the East German Business Forum Award

March 2021: Glatt Ingenieurtechnik celebrates continued business success with third expansion of its Technology Center

Published article: ‘New Battery Material by Powder Synthesis’ PDF, English

Published article: ‘Glatt Powder Synthesis – Pioneering Process for Groundbreaking Particle Synthesis’ PDF, English