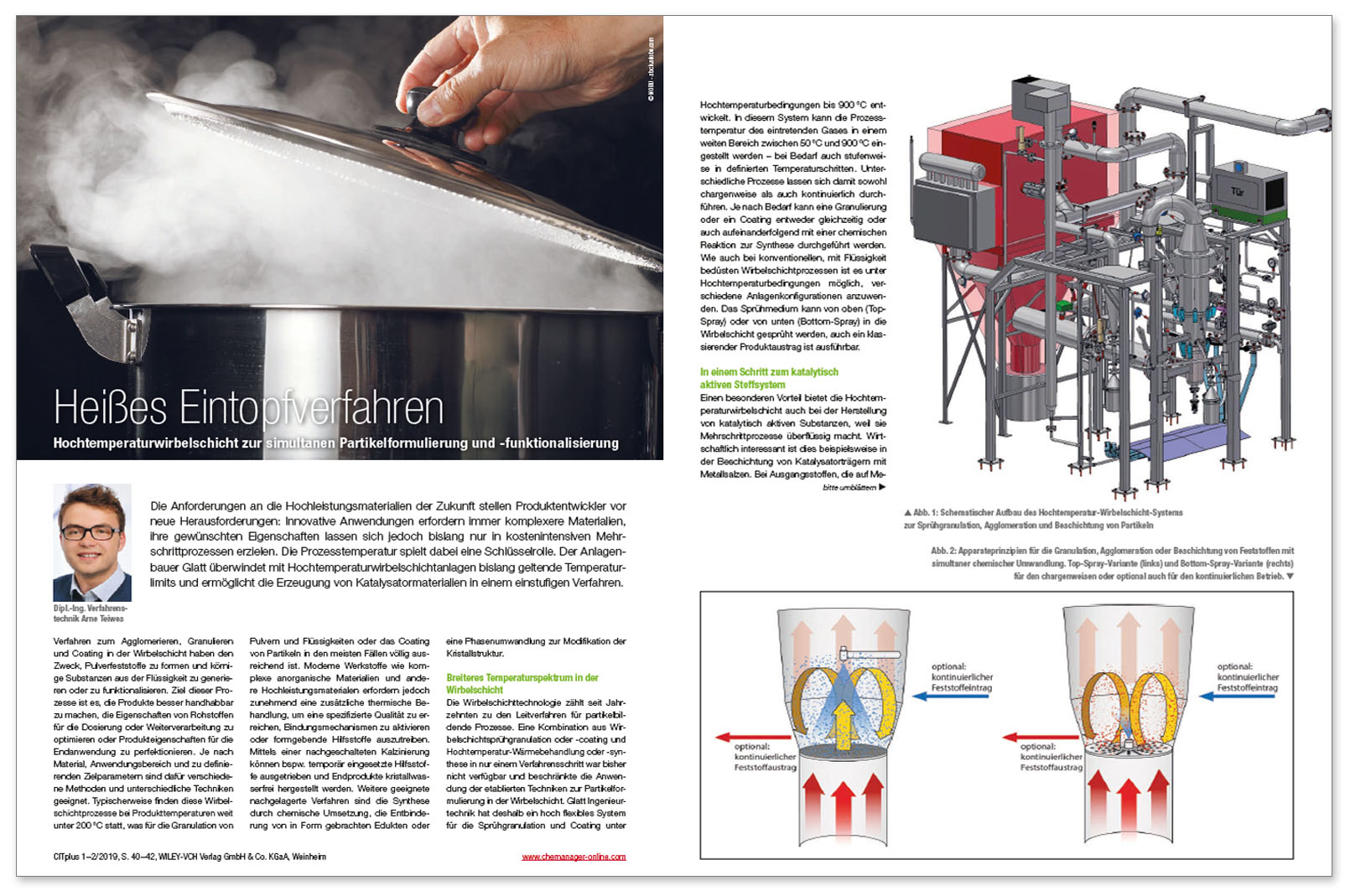

Hot one-pot process – High temperature fluidized bed for simultaneous particle formulation and functionalization (German Article)

The requirements for the high-performance materials of the future pose new challenges for product developers: Innovative applications require increasingly complex materials, but their desired properties can so far only be achieved in cost-intensive multi-step processes. The process temperature plays a key role here. With high-temperature fluid bed systems, plant manufacturer Glatt overcomes previously applicable temperature limits and enables the production of catalyst materials in a single-step process. (Article in German language)

- Author: Arne Teiwes, Graduate Engineer for Process Engineering, Process Technology Food, Feed & Fine Chemicals bei Glatt Ingenieurtechnik

- originally published in: CITplus, Ausgabe 01/2019, Wiley-VCH Verlag GmbH & Co. KGaA

Further information on this topic and related topics can also be found in the following publications:

March 2022: Glatt expands technology center with new laboratory plant for powder synthesis

Published article: ‘Ceramic Raw Materials from the Pulsating Hot Gas Stream’ PDF, English

Published article: ‘New Battery Material by Powder Synthesis’ PDF, English

Published article: ‘The gentle processing of highly volatile oils by fluid bed and spouted bed technology’ PDF, English

Published article: ‚Forward-looking plant planning – How pre-engineering can bring ideas to market faster‘ PDF, English

Copyright: Vereinigte Fachverlage

Copyright: Vereinigte Fachverlage Copyright: Palladian Publications

Copyright: Palladian Publications