Tailor-made Processes for Tailor-made Products

The key to the optimum product lies in the correct selection of process parameters and in the multitude of their possible combinations.

More performance for your product

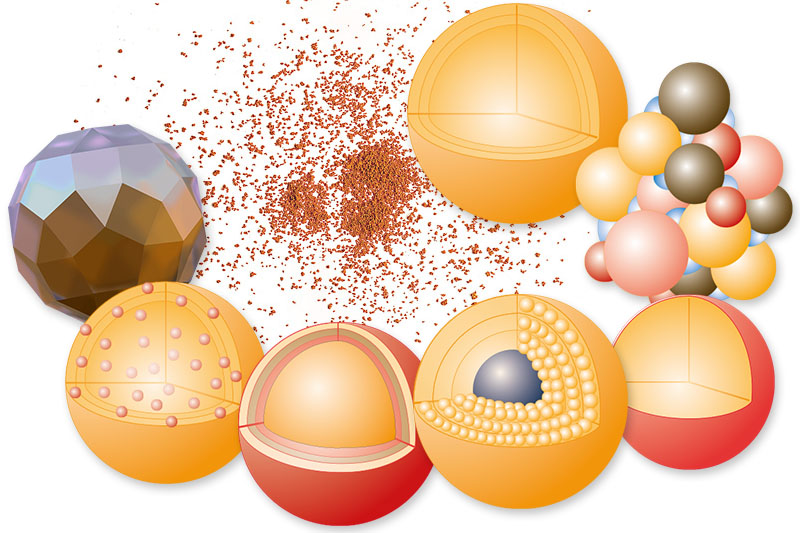

In processes with innovative Glatt technologies such as powder synthesis, fluid bed and spouted bed, you have almost unlimited possibilities for optimal particle design and suitable functionalization of bulk particles.

Whether spray granulation, spray drying, agglomeration, micro-encapsulation, coating, layering or calcination – the key to the optimum product lies in the right selection of process parameters and in the multitude of their possible combinations.

Maximum process flexibility for defined product properties such as bulk density, residual moisture, porosity or particle size distribution

All Glatt technologies score with the advantage that bulk materials in the form of powders, granules or pellets can be produced in a single process step that includes drying, unification, layering and consolidation and combines the overall mechanism of particle design. Various technical options offer – depending on customer requirements – different process flexibilities and final product properties such as bulk density, residual moisture, porosity or particle size distribution.

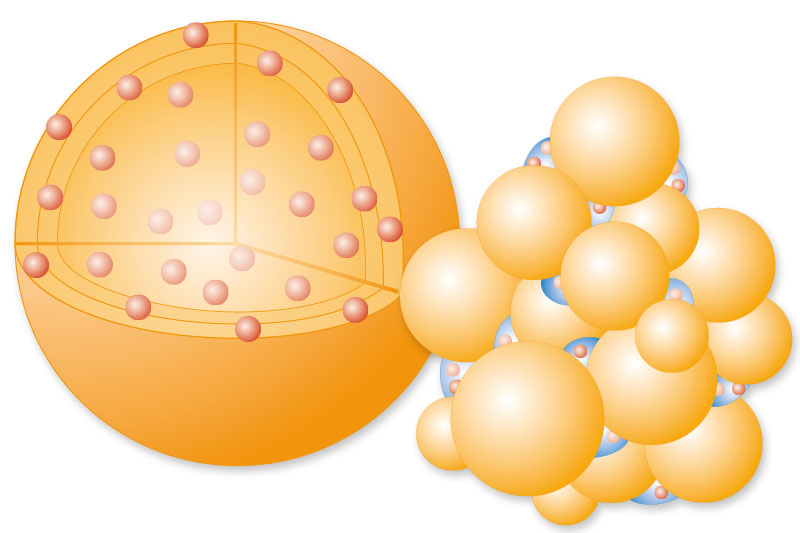

Spray Granulation

Drying and granulate build-up from liquids containing solids

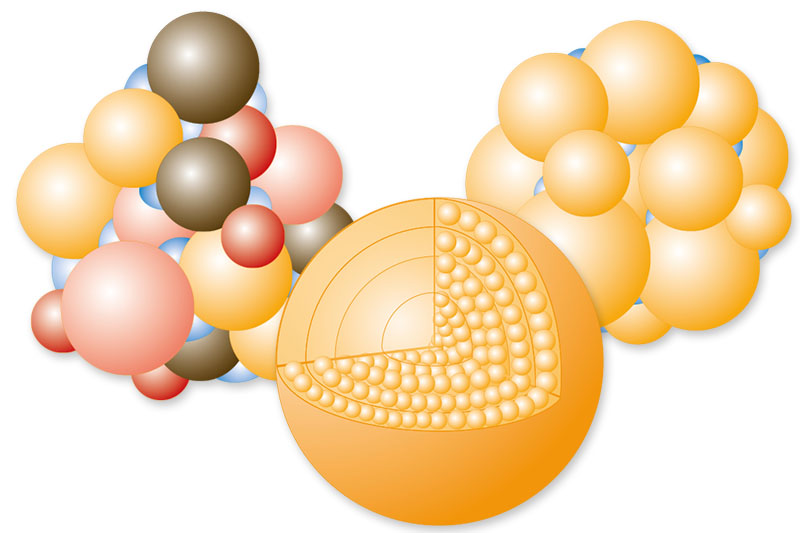

Agglomeration

Spray agglomeration, wet granulation or direct pelletizing of powders

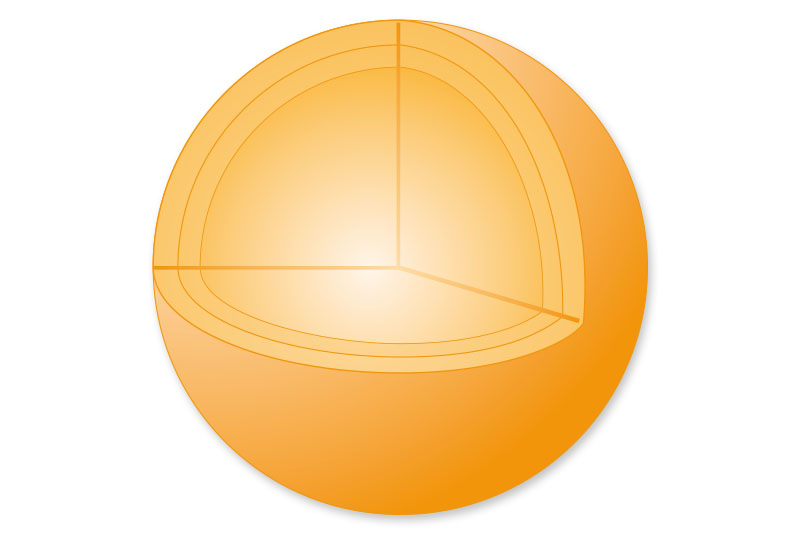

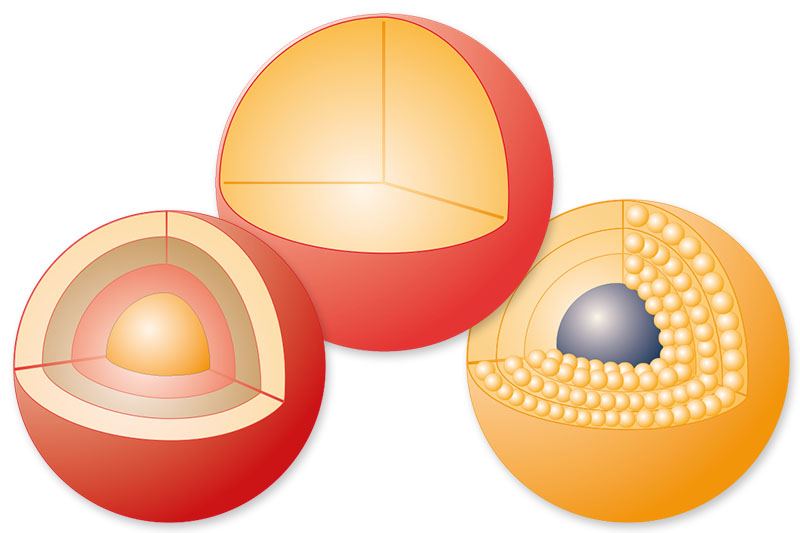

Particle Encapsulation

Uniform encapsulation with defined layer by coating or layering

Micro-encapsulation

Encapsulation of sensitive, active or volatile substances in a matrix

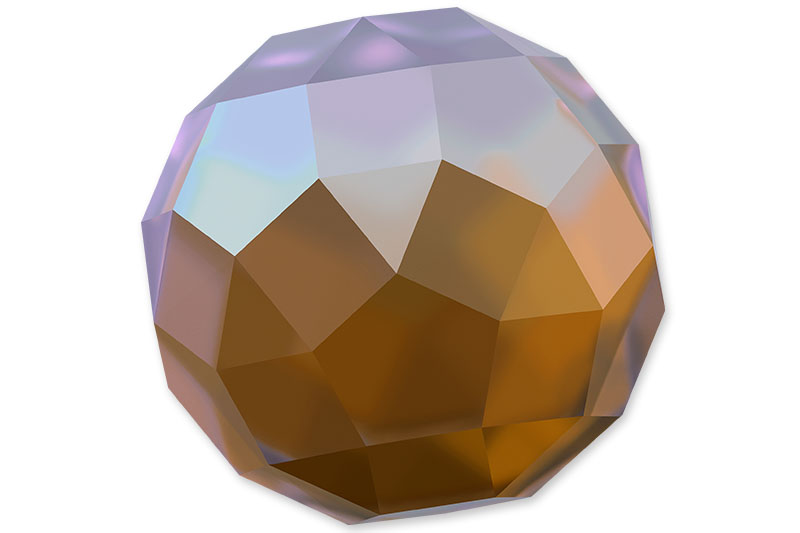

Spray Calcination

Thermal treatment or synthesis of particles: Generation, dehydration, chemical conversion