Spray Calcination

Homogeneous micro- and nanopowders by shaping, drying and calcination in only one process step

Precise design of completely new powder types with precisely adjusted properties

Glatt powder synthesis is an improved process for spray drying and spray calcination of fine powders for various applications. These include, for example, raw materials for batteries, catalysts or high-end ceramics. The special feature of this technology is drying and calcination in a pulsating hot gas stream. The variation of the pulsation parameters influences the particle morphology as well as the crystalline structure of the product. In this way, your micro- and nanopowders can be excellently adapted to your specific requirements. Decoupling these parameters from the process temperature allows drying of very sensitive raw materials at lower temperatures. Particle formation, drying and calcination take place in only one process run.

The process of spray calcination with Glatt powder synthesis offers several advantages, which make the design and production of your powders particularly efficient.

By using stock solutions as the starting material, even the smallest quantities of doping elements can be homogeneously distributed in the product. You can react immediately to changing requirements and modify the desired product properties quickly and easily.

Fine atomization and interaction with the pulsating gas flow enable the production of powders in the micro- and submicrometer range. The large specific surface area of such powders has a very high reactivity. The result is, for example, improved catalytic properties or lower sintering temperatures.

Increased reactivity can also be achieved by thermodynamic disequilibrium states in the powder material. As a result of very rapid drying combined with rapid cooling at the reactor outlet, high-temperature phases are frozen or amorphous structures are formed, which often prove useful.

Spray calcination takes place in our pulsation reactors in a continuous mode of operation.

Product properties of micro and nano powders particles from spray calcination using Glatt powder synthesis in pulsating gas flow at a glance:

Narrow

Particle Size Distribution

High

Specific Surface Area

Highest

Degree of Purity

Highest

Homogeneity

Without

Hard Aggregates

Unique

Particle Structures

Micro- and nanopowders produced by Glatt powder synthesis are characterized by particular homogeneity:

The dissolved raw materials allow uniform distribution of even low concentrations of dopants in the product. Controlled atomization and subsequent secondary atomization result in narrow particle size distributions. The strong mixing of process gas and product in the synthesis reactor leads to very low temperature and residence time gradients.

This homogeneity is a basic prerequisite for high-quality powders that exhibit reproducible properties during further processing as well as in the final application.

Product example

Synthesized BSCF powder, catalytically active oxide ceramic, spray calcinatio, REM

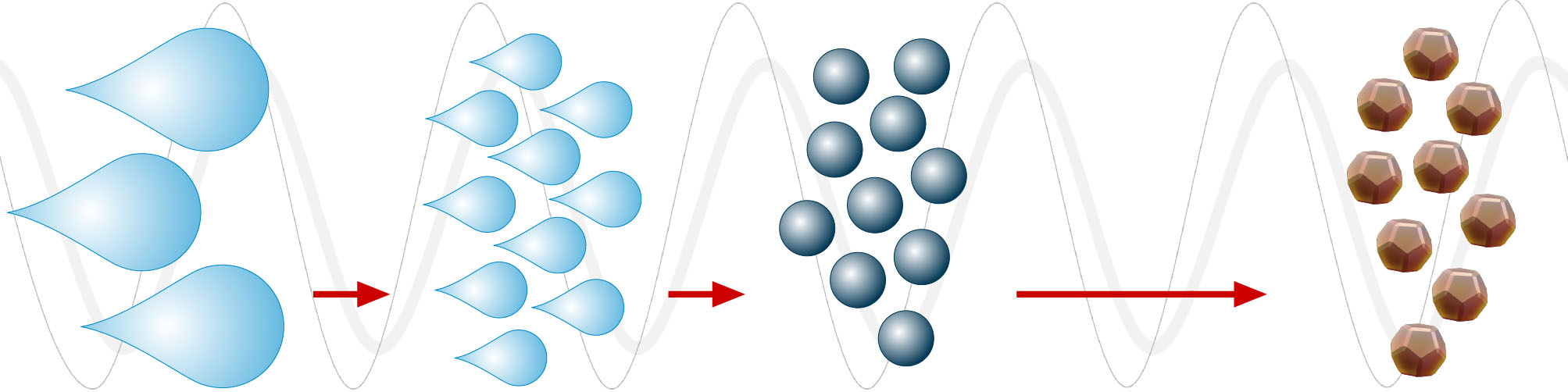

The spray calcination process in detail

In particle design with Glatt powder synthesis, process steps such as drying, particle formation and calcination are combined in a single step. During powder production, all particles undergo the same thermal treatment.

- Spraying a raw material solution into the gas stream produces small droplets

- Pulsating gas flow produces even smaller droplets by secondary droplet decomposition

- Evaporation of the solvent causes solid powder particles to form very quickly from the droplets

- Optionally, the powder can be thermally posttreated (e.g. calcined) with appropriate temperature control

Glatt powder synthesis to develop and produce your specific high performance powder materials

Further information on this topic can also be found in the following publications:

Published article: ‘New Battery Material by Powder Synthesis’ PDF, English

Published article: ‘Coated zirconia for medical technology by specialized powder synthesis’ PDF, German

Published article: ‘Glatt Powder Synthesis – Pioneering Process for Groundbreaking Particle Synthesis’ PDF, English

Published article: ‘From Hot Gas Stream to Matt Finish by Glatt Powder Synthesis’ PDF, English

March 2022: Glatt expands technology center with new laboratory plant for powder synthesis