Film Coating, Lipid Coating, Hotmelt Coating

Spray coating in the fluidized bed or spouted bed.

Functionalization of particle surfaces.

Sensory attractiveness.

Protective mechanisms.

Release control.

Targeted influencing of the surface structure of particles through the application of functional coatings.

Spray coating – film coating, lipid coating or hot melt coating – in the fluid bed and spouted bed is an effective process for applying protective films and functional layers, for example to increase shelf life or storage stability. Colored brandings can be realized as well as the enhancement of sensory attractiveness, for example for odor and taste masking. Particle properties such as those for retardation or controlled release can also be specifically influenced by means of film coating, lipid coating or hot melt coating.

It is important to apply the coating material very uniformly. Application and solidification take place in a single system. The film material is applied from a solution, a suspension or as a melt. The specific choice of process parameters prevents the formation of liquid bridges and avoids undesirable agglomeration during film application.

Particles of different shapes and sizes can be moved in the fluid bed or spouted bed and sprayed with liquids in the process. Particles and granules previously produced by spray granulation, agglomeration, active material layering or spray drying can be additionally functionalized by spray coating. Typical particle sizes are 100 micrometers to 3 millimeters.

Film coating, lipid coating or hot melt coating processes in fluid bed systems and spouted bed systems can be carried out in batch operation or in a continuous process.

For protective coatings and new functions for micro- and nanopowders, Glatt offers core-shell coating in the pulsating gas stream of Glatt powder synthesis.

These product properties can be specifically influenced by means of film coating, lipid coating or hot melt coating in the fluid bed or spouted bed:

Active

Ingredient Release

Odor and

Taste

Shelf-life /

Storability

Optical

Attractiveness

Surfaces

Structure

Light / UV

Sensitivity

Solubility

Flow Behavior

Sorption Behavior /

Hygroscopicity

Thermal

Stability

Chemical

Compatibility

Oxidation

Stability

Mechanical

Strength

Retardation /

Resolution Delay

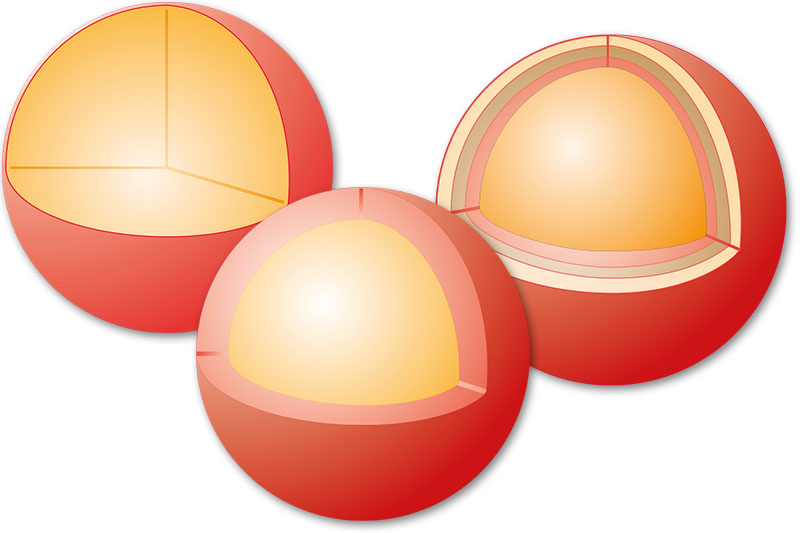

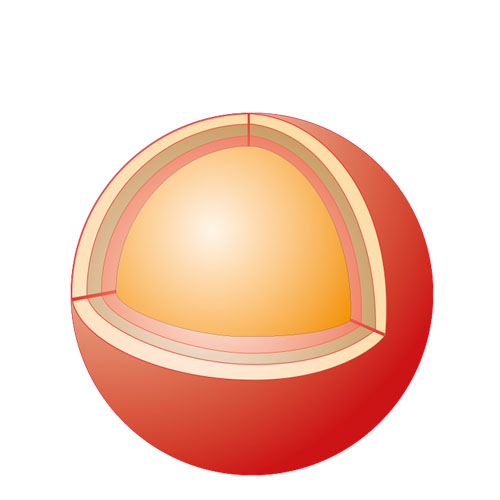

Multilayer Coating for Staggered Functionality

Wide range of variants

Coating layers can be realized in different ways, depending on the requirements for the product properties.

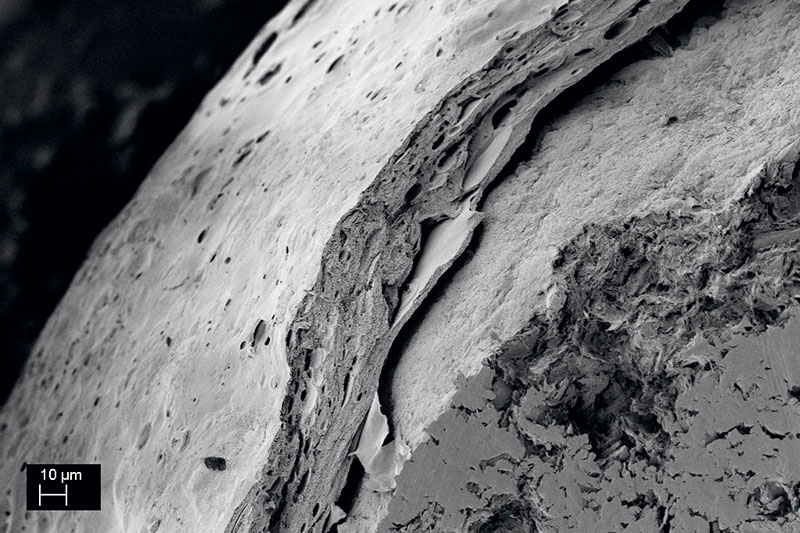

Film coating is a very effective process for applying ultra-thin, functional barrier, protective and color layers or other functional coatings. When coating from a solution or suspension, the liquid serves to transport the solid onto the surface of the particles. The aqueous or organic solvent evaporates, and the solid contained in it forms the coating layer.

- low mass fraction of the functional layer in relation to the particle core provided

- layer thicknesses between approx. 5 and 50 micrometers (and more)

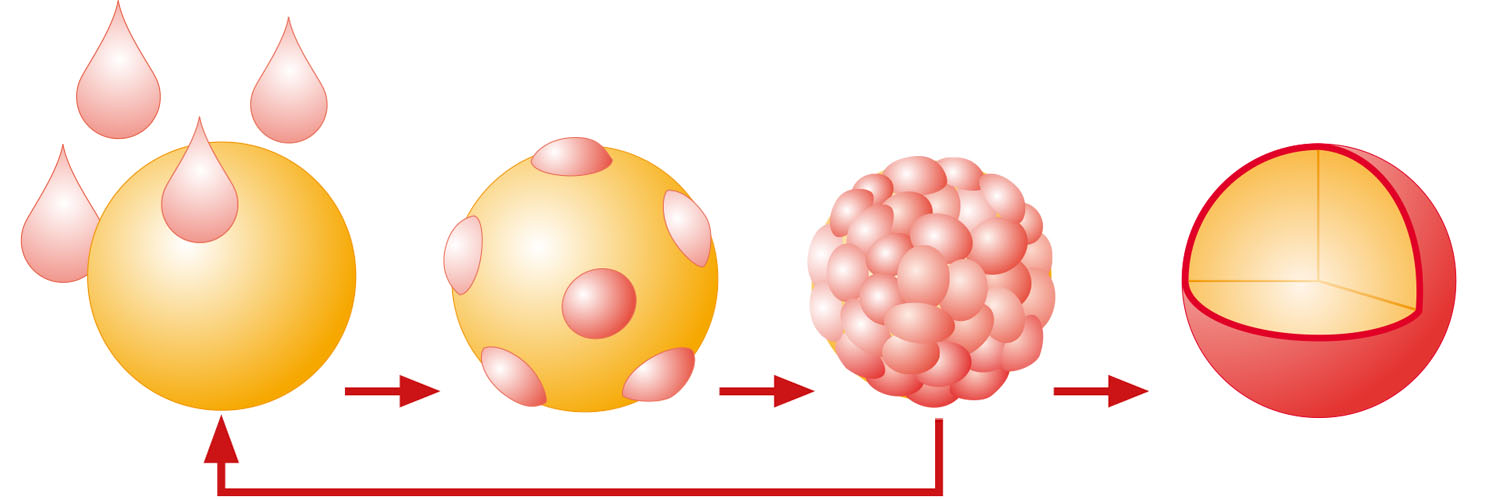

Lipid coating as well as hot melt coating are very effective processes for coating or encapsulating particles by applying melts and creating solid protective films for influencing particle properties by solidification.

- fast film application

- no solvent evaporation necessary

- small to large coating masses in relation to the particle applied

- layer thicknesses between approx. 25 µm and several 100 µm

- dense release layers with multilayer build-up

In hotmelt coating, the melt to be applied consists one hundred percent of coating material in a spreadable state. The particle shell is formed here by solidification of the sprayed-on melt. Well suited for rapid coating application. The use of melts as coating liquid also eliminates the energy-intensive evaporation of solvents.

For coating very finely divided or irregularly structured particles, spouted bed coating or fluid bed HS Wurster coating is suitable.

Product examples

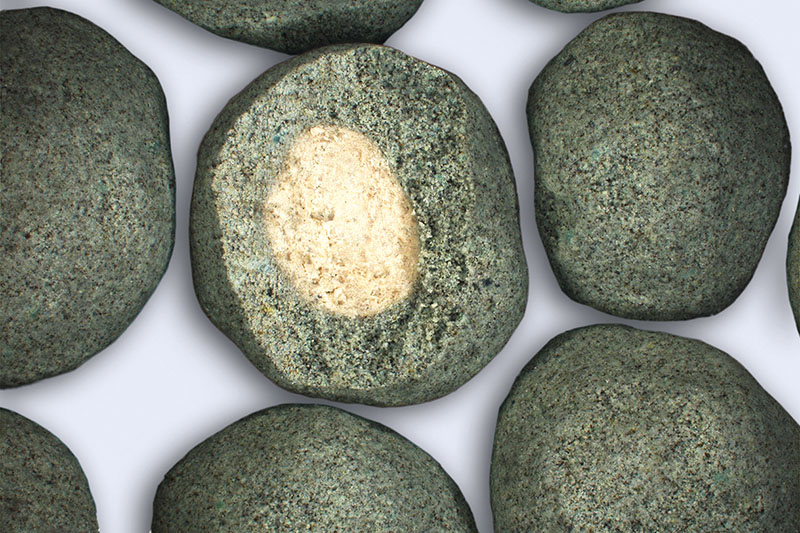

Fertilizer, branding by film coating

Enzymes, protection by film coating

Seed with functional layer by film coating

Catalysts with functional coating layer

Coated enzyme pellet, REM

The process of film coating, lipid and hotmelt coating in detail

Application of ultra-thin layers in film coating: The coating material is applied by spraying the solids-containing liquid onto the fluidized particles, and the film is dried and solidified in a single process step. The coating liquid is sprayed onto precoated solids. The supplied process air evaporates the liquid and dries the film layer. Small droplets and low viscosity ensure uniform distribution and thus a high-quality film.

Fast and high layer application in lipid coating or hotmelt coating. The particle shell is formed here by solidification of the sprayed-on coating material. No evaporation of solvents required.

Dense release layers in multilayer structures for increased functionality

Encapsulation of particles by means of film, lipid and hotmelt coating

Glatt film, lipid and hotmelt coating in the fluid bed, continuous operation

Glatt HS-Wurster High-speed coating in the fluid bed, batch operation

From the product idea to production

In our Glatt Technology Center, we provide you with access to sophisticated technologies and support in formulation, product and process development, tailored to your individual requirements. The process always starts with tests on a laboratory system. The in-house analytics laboratory enables in-process analyses to adapt particle properties to the respective application. For reliable scale-up, process and operating parameters are determined on pilot plants. Through contract manufacturing at Glatt, your new powders, pellets or granules can be manufactured, filled, packaged and delivered directly in agreed quantities. As a plant manufacturer, Glatt provides all services from project initiation, development and realization through to turnkey production in your own plant.

Further information on this topic and related topics can also be found in the following publications:

Published article: ‘Spray (micro)encapsulation of sensitive substances in matrix form – An overview of essential oil and vitamin case studies’ PDF, English

Published article: ‘Fomulation For Success – Fluid Bed Systemes as Key for the Production of Speciality Fertilizers’, PDF, English

Published article: ‘Optimizing end products with finely tuned process parameters’ PDF, English

Published article: ‘Enhancing product properties with fluid bed and spouted bed technologies’ PDF, English

Published article: ‘Hot-melt applications for the food and beverage industry – How to safely stabilize vitamins and probiotics’ PDF, English